In the world of home improvement and renovation, the efficiency of an application device plays a crucial role in achieving seamless results. Familiarity with the individual elements that contribute to its functionality enhances the user experience and ensures optimal performance. This section delves into the essential components, providing insights into their roles and importance.

Each segment of the device works in harmony to facilitate smooth operation and effective results. From the mechanism responsible for fluid movement to the sections that allow for precise adjustments, understanding these components is vital for both novice and experienced users alike. By mastering the intricacies of this application tool, one can elevate their projects to a new level of quality and efficiency.

Additionally, recognizing the interplay between various elements can aid in troubleshooting and maintenance, ensuring longevity and reliability. A well-informed user can easily identify issues and address them promptly, minimizing downtime and enhancing overall productivity. This knowledge not only empowers users but also fosters a deeper appreciation for the technology behind their essential tools.

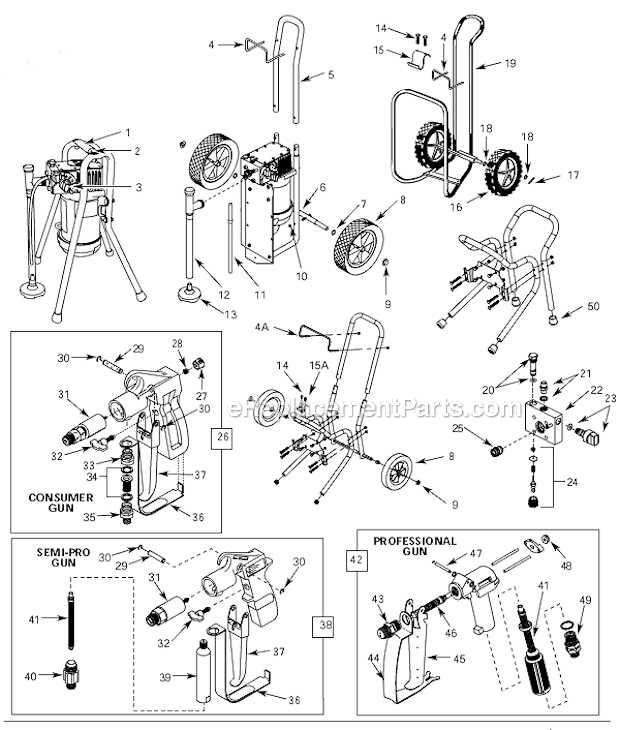

Understanding the essential elements of high-quality spraying devices is crucial for achieving optimal results in various applications. These components work in harmony to ensure efficiency and effectiveness during operation, providing users with the tools necessary for successful tasks.

Essential Elements

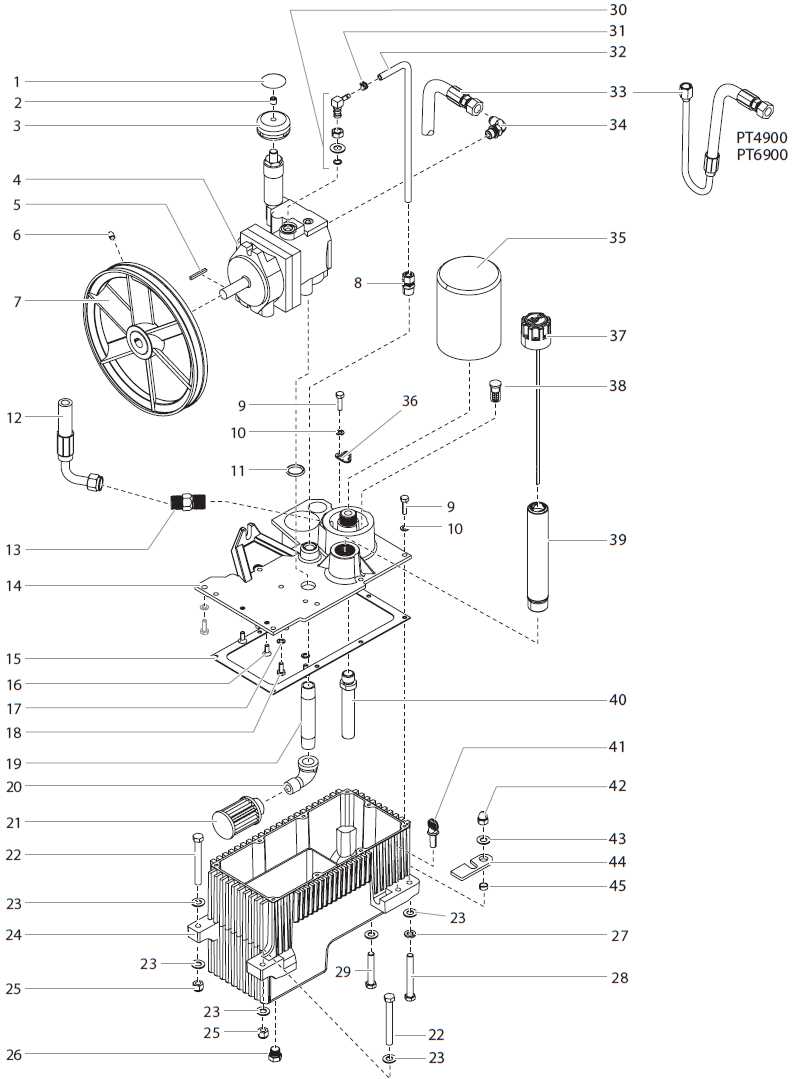

- Motor: The heart of the system, driving the entire operation.

- Pump: Responsible for pressurizing the fluid, ensuring a consistent flow.

- Gun: The point of application, allowing for precise control and even coverage.

- Nozzle: A critical component that dictates the spray pattern and width.

- Hoses: Flexible conduits that transport the material from the pump to the gun.

Additional Features

- Filters: Prevent clogs by removing debris from the fluid.

- Pressure Control: Enables adjustment of the spraying force for various materials.

- Wheels: Enhance portability, allowing for easy movement around the workspace.

Understanding the Function of Each Part

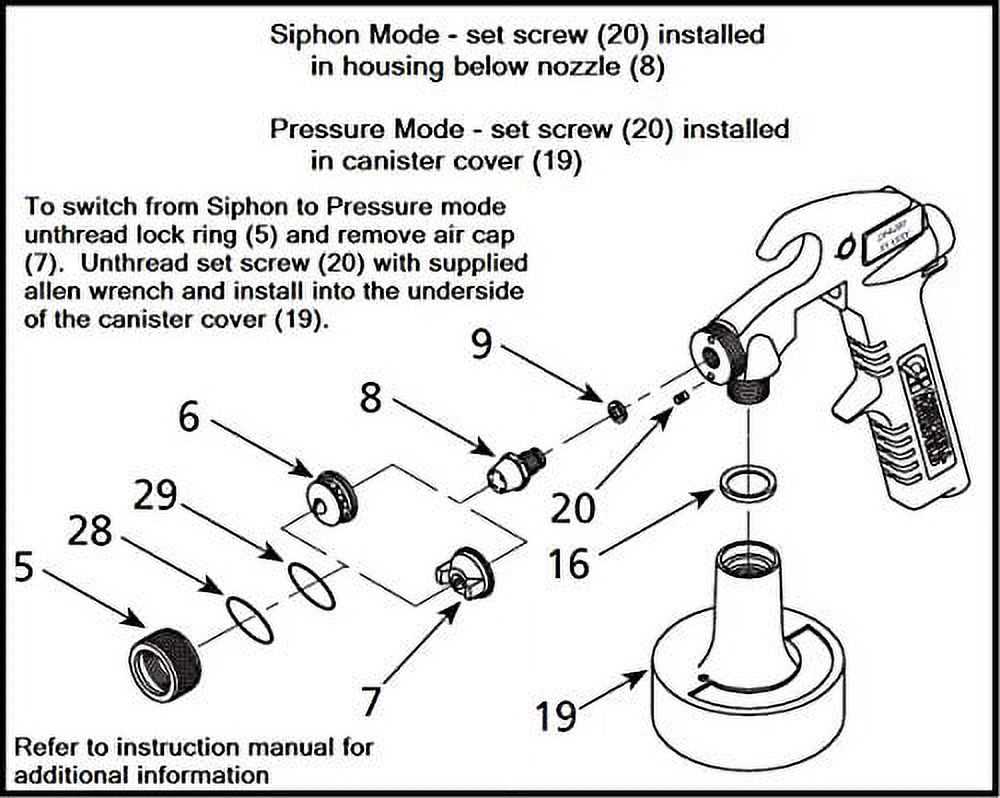

The various components of a spraying apparatus each play a crucial role in the overall performance and efficiency of the device. By grasping the purpose of these individual elements, users can enhance their understanding of how the equipment operates and optimize its usage for different tasks.

Every component contributes to the delivery of the liquid medium, ensuring it is applied uniformly and effectively. For instance, the motor is essential for generating the necessary pressure, while the hose transports the mixture to the nozzle. Additionally, the nozzle controls the flow and pattern of the application, affecting the final result significantly.

Moreover, the filter prevents debris from clogging the system, ensuring smooth operation and consistent output. Each element’s interaction is vital for achieving the desired finish, making it imperative to recognize their functions and maintain them properly for optimal performance.

Common Issues with Paint Sprayers

When using spray equipment, users may encounter several typical challenges that can affect performance and the quality of the finish. Understanding these issues can help in troubleshooting and ensuring a smoother application process.

- Clogs: One of the most frequent problems is clogging, which can occur in the nozzle or filter. This can lead to uneven spraying and require frequent cleaning.

- Inconsistent Flow: Variations in fluid delivery can result in splotchy coverage. This may be due to improper pressure settings or blockages within the system.

- Over-spray: Excessive misting of the material can create a mess and waste resources. Proper distance from the surface and technique can mitigate this issue.

- Poor Atomization: If the material does not break up into fine particles, it can lead to a rough finish. This may be caused by incorrect nozzle size or pressure adjustments.

- Equipment Malfunction: Mechanical failures can arise from wear and tear or lack of maintenance. Regular inspections and servicing can help prolong the lifespan of the device.

By being aware of these common challenges, users can take proactive measures to maintain their equipment and achieve better results.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your equipment. By following specific maintenance practices, you can extend its lifespan and maintain optimal performance, avoiding common issues that may arise from neglect. This section outlines key strategies to help you preserve your machinery in excellent condition.

Routine Cleaning

Maintaining cleanliness is vital for the functionality of your device. After each use, thoroughly clean all components to prevent the buildup of residue that can hinder performance. Utilize appropriate cleaning solutions and tools to ensure that every part is free from obstructions.

Periodic Inspections

Conducting regular assessments allows you to identify potential problems before they escalate. Check for any signs of wear or damage, and address issues promptly to prevent further complications. Staying proactive in your inspections can save you time and money in the long run.

| Maintenance Activity | Frequency | Notes |

|---|---|---|

| Clean components | After each use | Use suitable cleaning agents |

| Inspect for damage | Monthly | Look for wear and tear |

| Lubricate moving parts | Every 3 months | Follow manufacturer’s guidelines |

| Replace worn parts | As needed | Check during inspections |

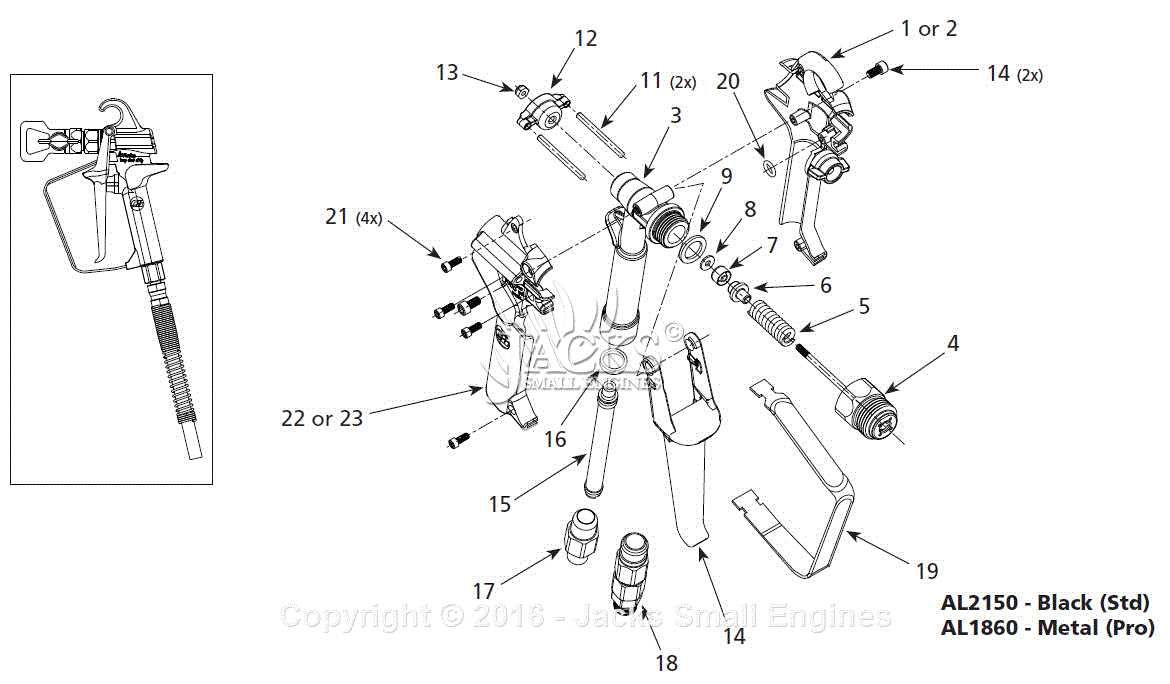

How to Identify Replacement Parts

Understanding how to recognize essential components for your equipment is crucial for maintaining optimal functionality. Knowing the specific attributes of each element will help ensure that you select the correct replacements when necessary. This guide aims to assist you in navigating the various aspects of identifying and sourcing these critical elements effectively.

Check the User Manual

The first step in identifying the necessary components is to refer to the user guide provided with your device. This document typically includes comprehensive information about each element, including its specifications and functionality. If the manual is unavailable, many manufacturers offer digital versions on their websites.

Visual Inspection

Conducting a thorough visual examination can significantly aid in recognizing components that may need replacement. Look for any signs of wear, damage, or malfunction. Additionally, taking clear photographs can be beneficial when seeking assistance or purchasing replacements online. Always ensure that you match the dimensions and specifications to guarantee compatibility.

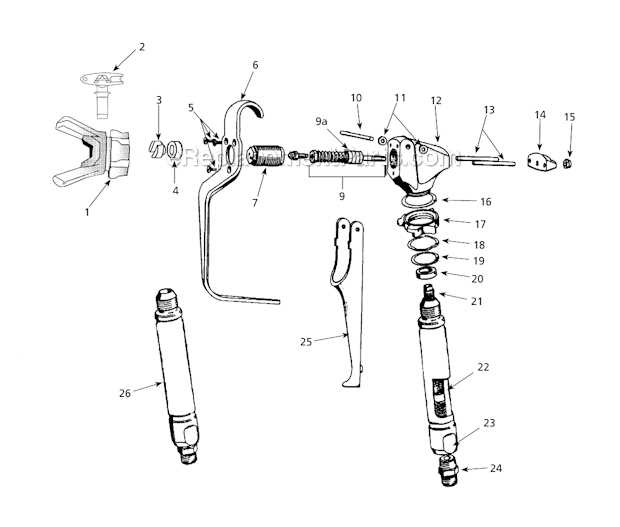

Using the Parts Diagram Effectively

Understanding the visual representation of components is essential for maintaining and repairing equipment. This guide provides insights into how to utilize such illustrations for efficient troubleshooting and assembly. Mastering this resource can significantly enhance your proficiency in handling machinery.

Begin by familiarizing yourself with the layout. Each section of the illustration often corresponds to specific functionalities or groups of elements. By recognizing these relationships, you can quickly locate issues and identify necessary replacements.

Pay close attention to the labels and notations. They offer crucial information about each element’s role and compatibility with others. Knowing these details will streamline your repair process and minimize the risk of using incorrect components.

Lastly, refer to the illustration regularly as you work on the equipment. Keeping it handy allows for real-time verification and aids in reinforcing your understanding of how various elements interact. This practice fosters greater efficiency and accuracy in your projects.

Benefits of Airless Painting Technology

The advancement in spraying technology offers numerous advantages that significantly enhance the efficiency and quality of surface application. This method allows for faster coverage and improved results, making it a preferred choice for many professionals and DIY enthusiasts.

Key advantages include:

- High Efficiency: The process enables quicker application, reducing the overall time required to complete projects.

- Smooth Finish: Provides a uniform and even coat, minimizing the appearance of brush or roller marks.

- Versatile Use: Suitable for a wide range of materials, including thick substances that may be difficult to apply with traditional methods.

- Less Cleanup: Often requires less cleaning effort, allowing for more focus on the task at hand.

- Greater Reach: Ideal for reaching tight spaces and high areas, ensuring comprehensive coverage without the need for ladders or scaffolding.

Overall, this innovative approach transforms how surfaces are treated, providing a practical solution for achieving professional-quality results with ease.