In the realm of mechanical tools, the effective functioning of any device relies heavily on the precise arrangement and interaction of its individual elements. Each component plays a crucial role, contributing to the overall performance and reliability of the system. A thorough comprehension of these elements not only enhances maintenance efforts but also aids in troubleshooting and optimizing efficiency.

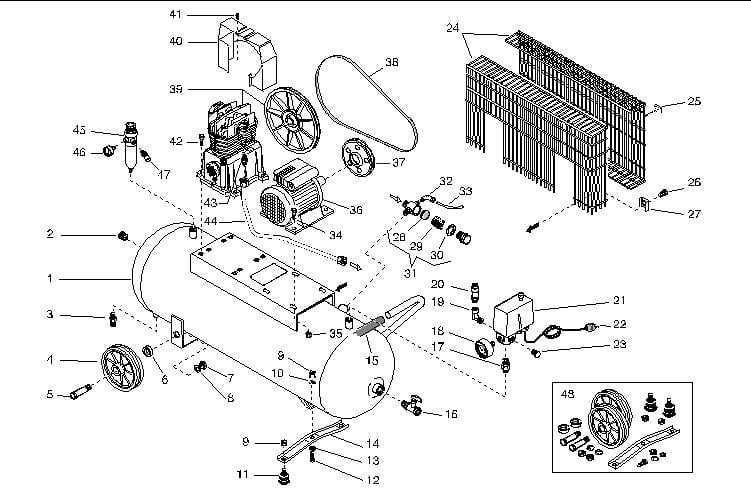

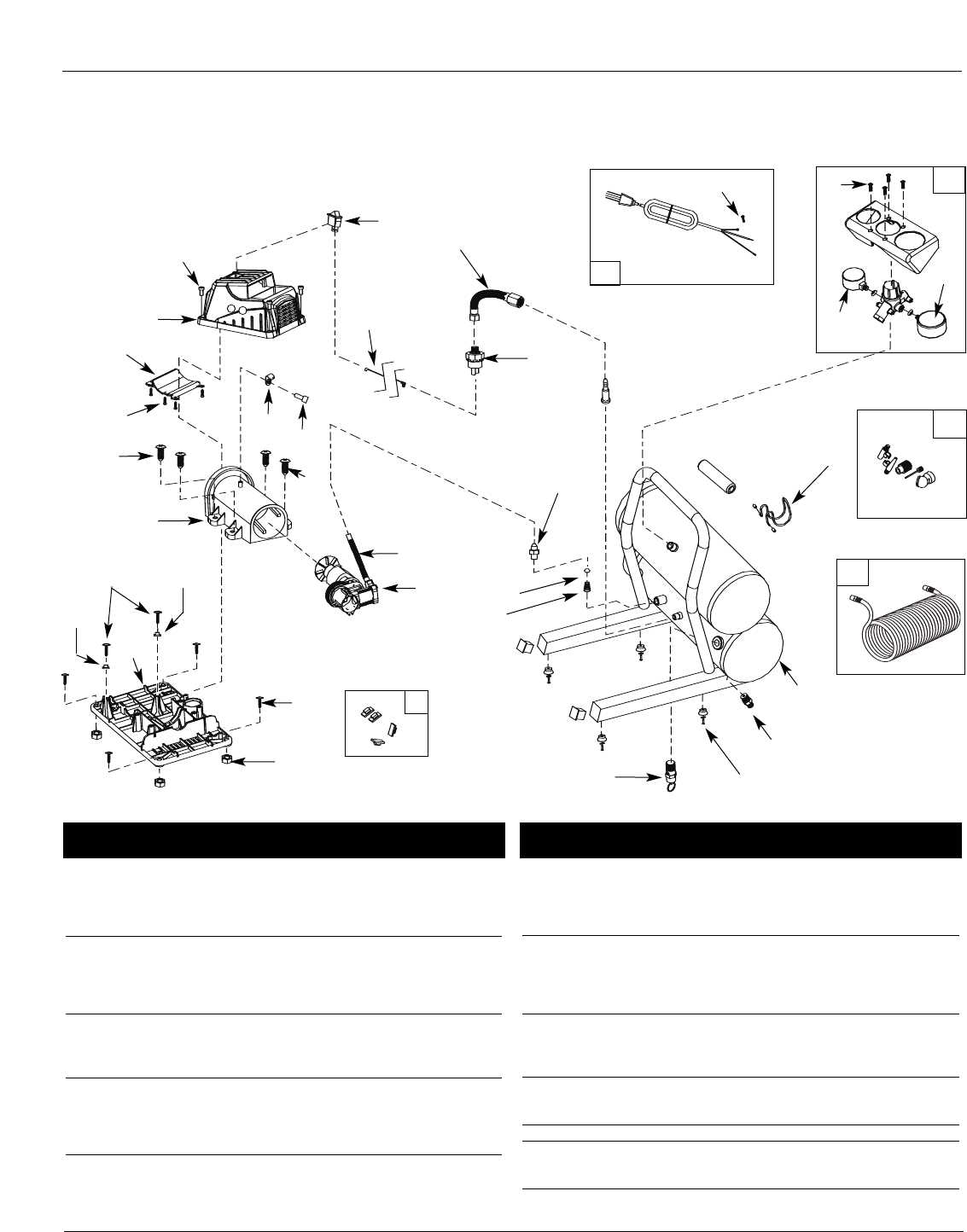

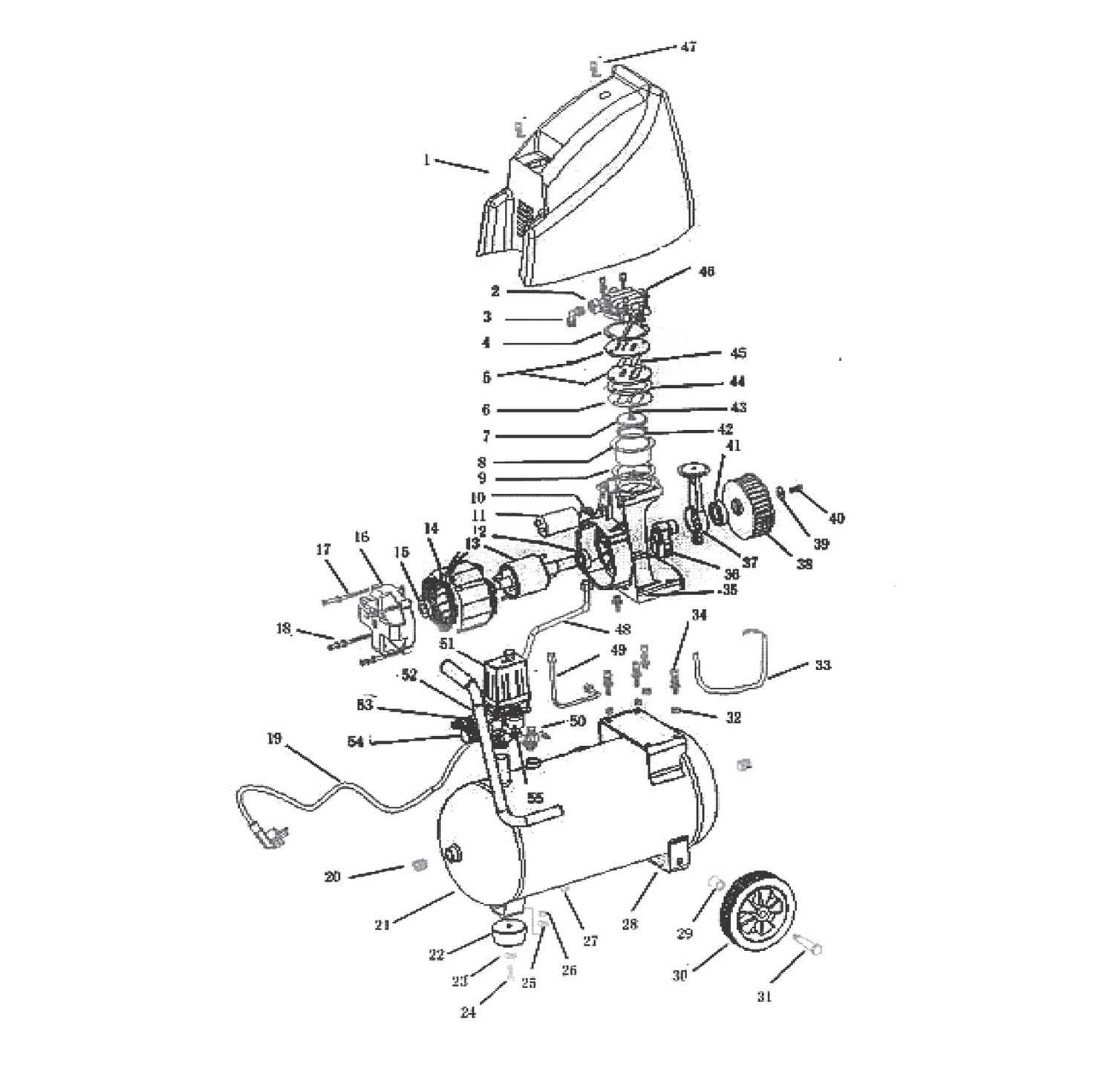

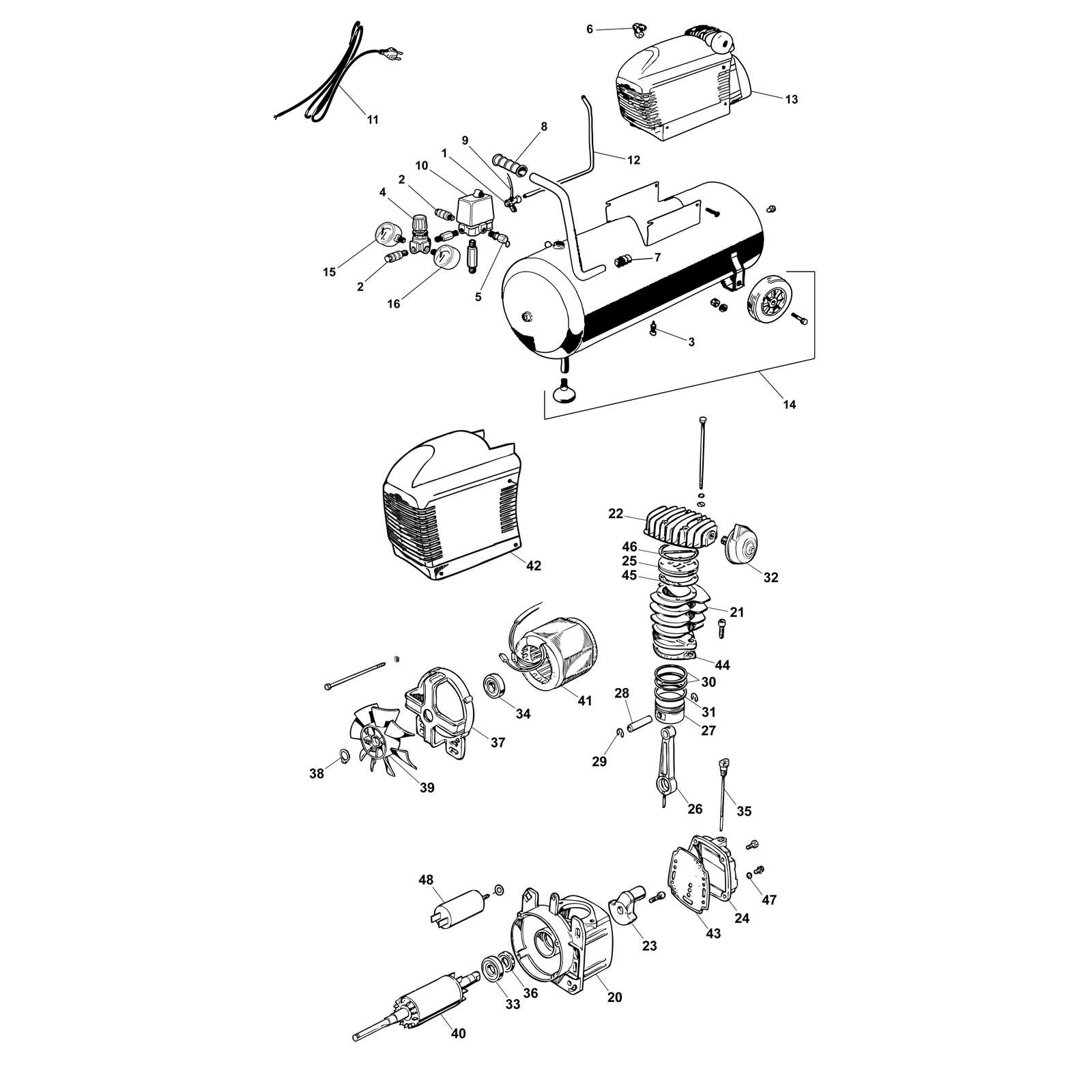

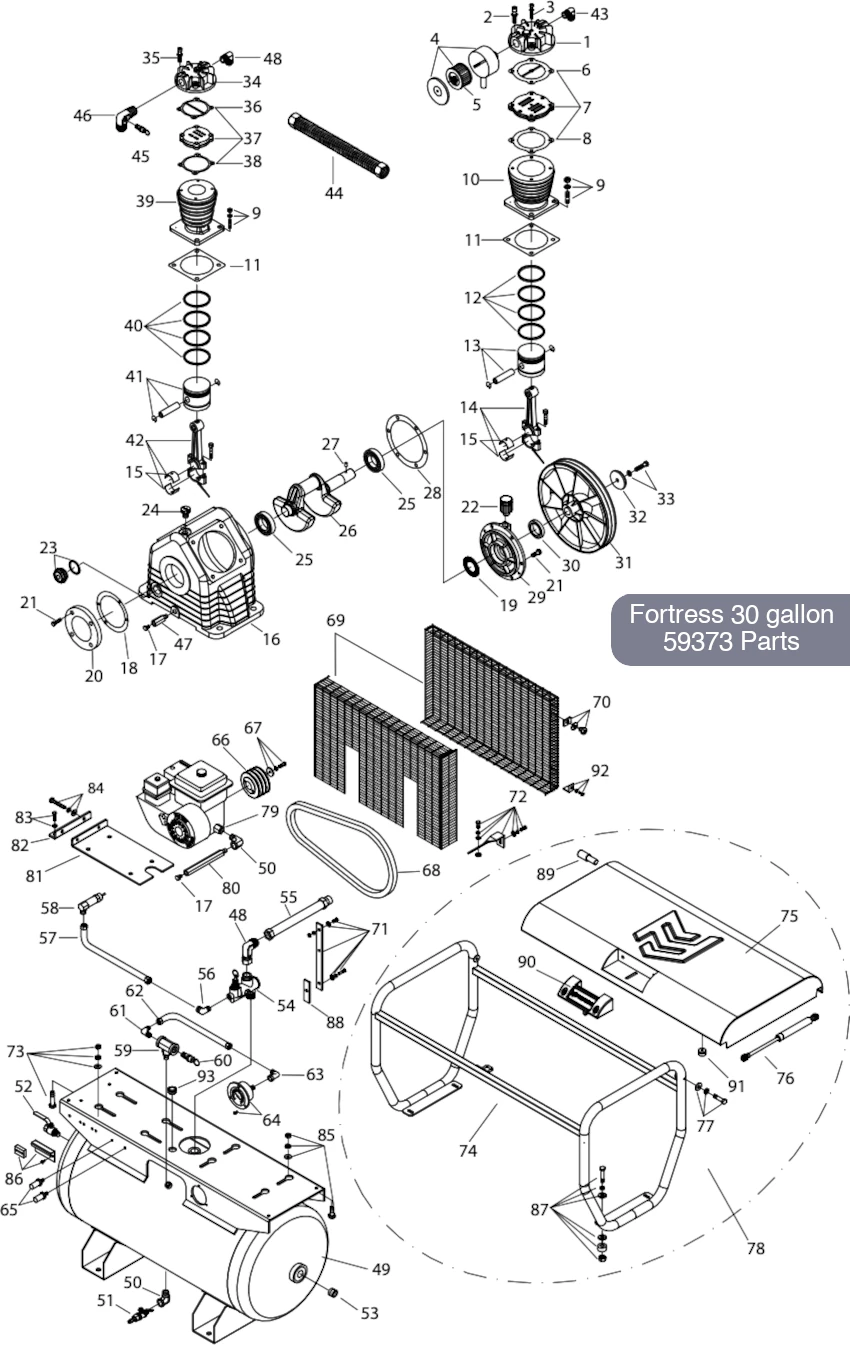

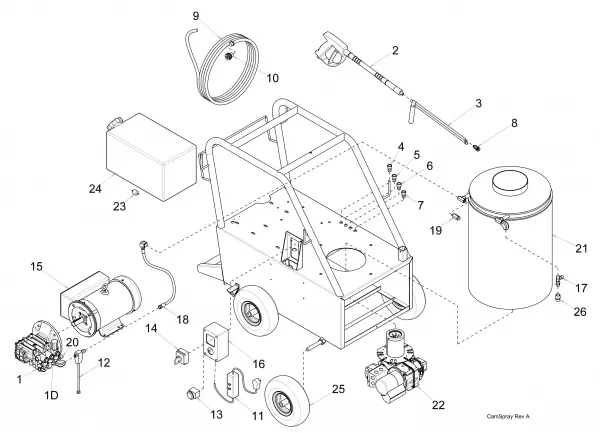

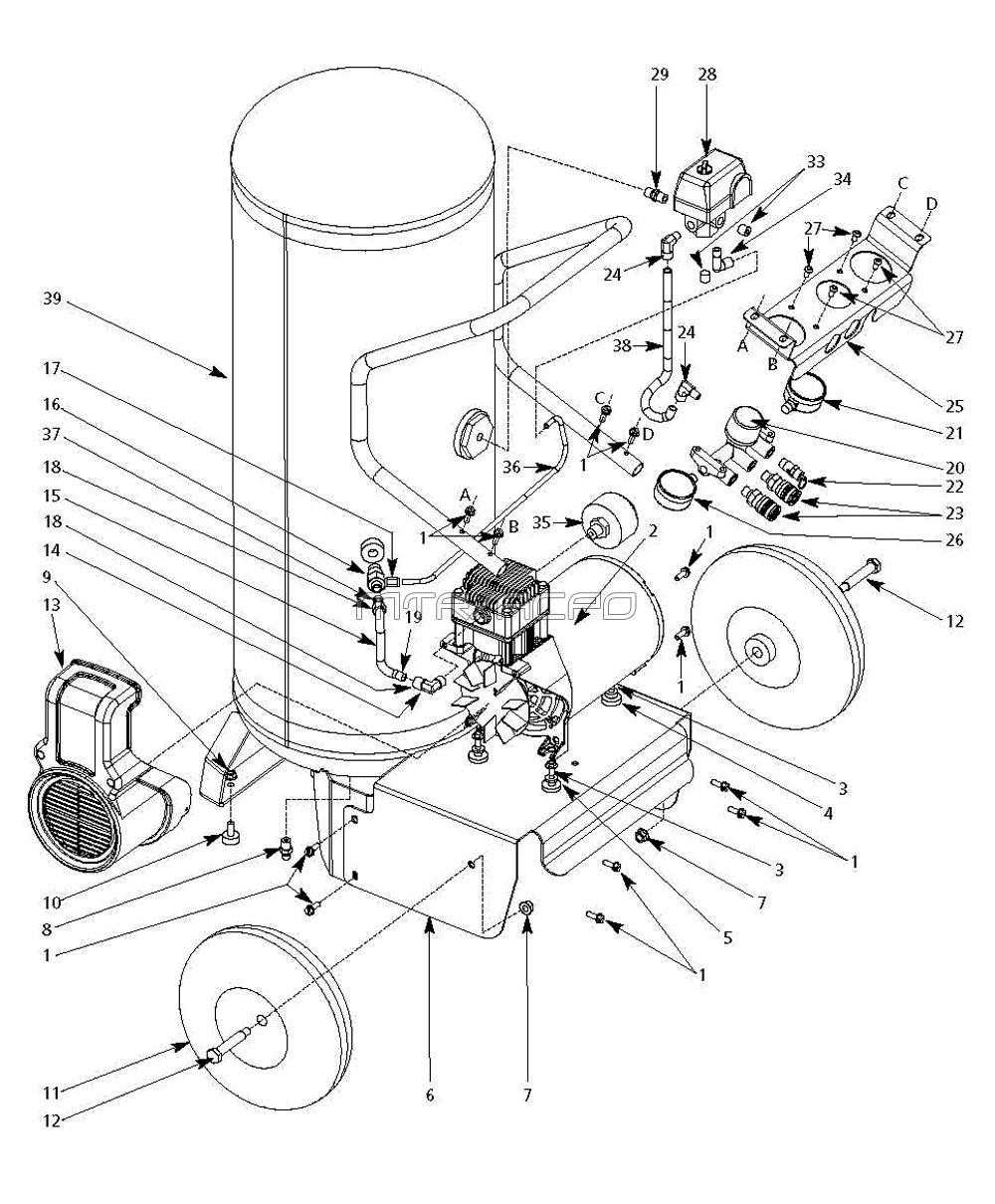

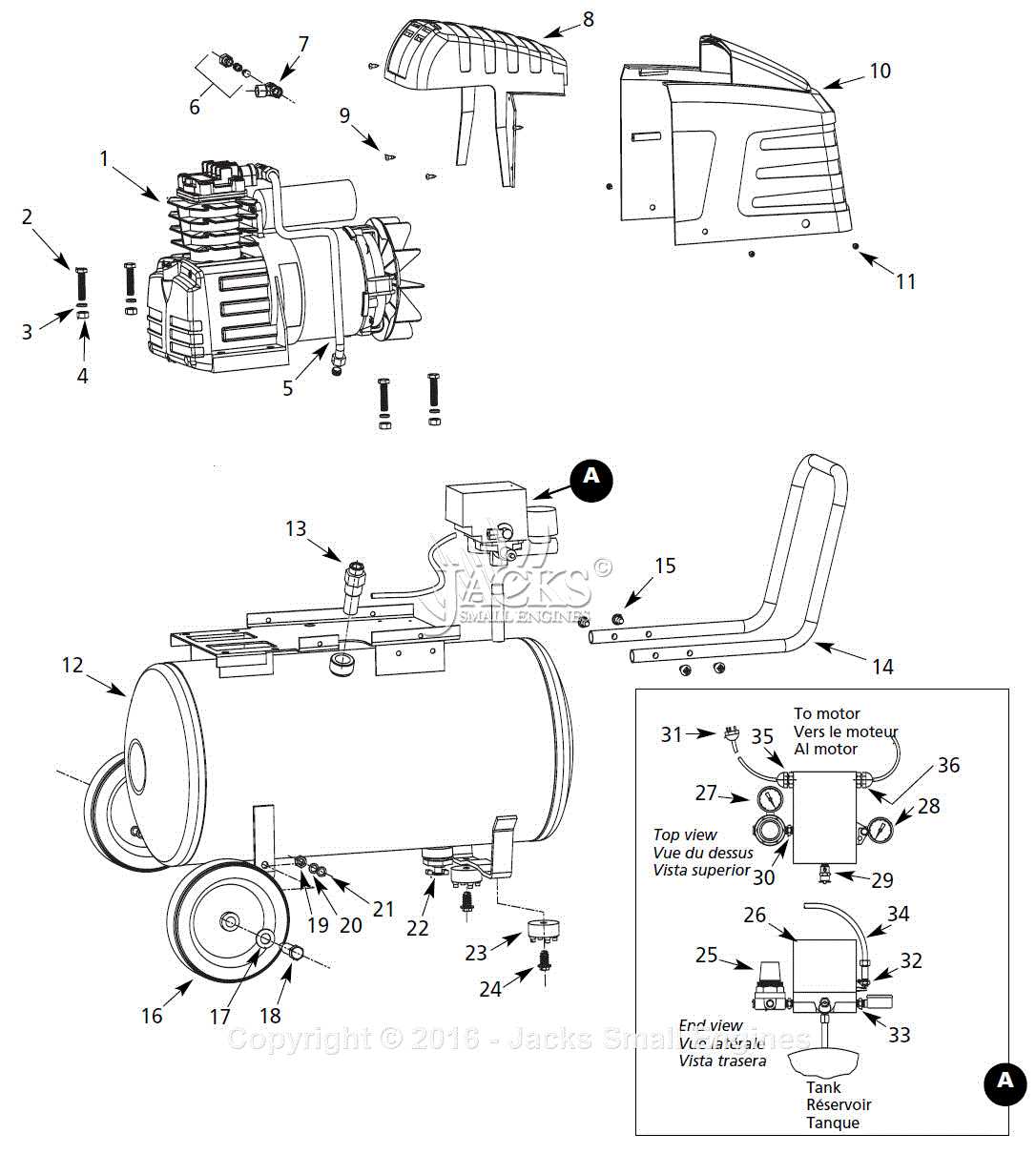

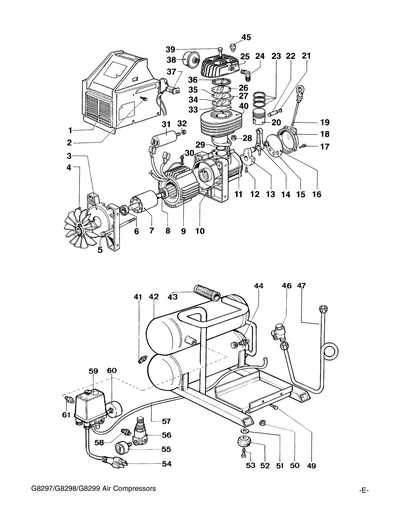

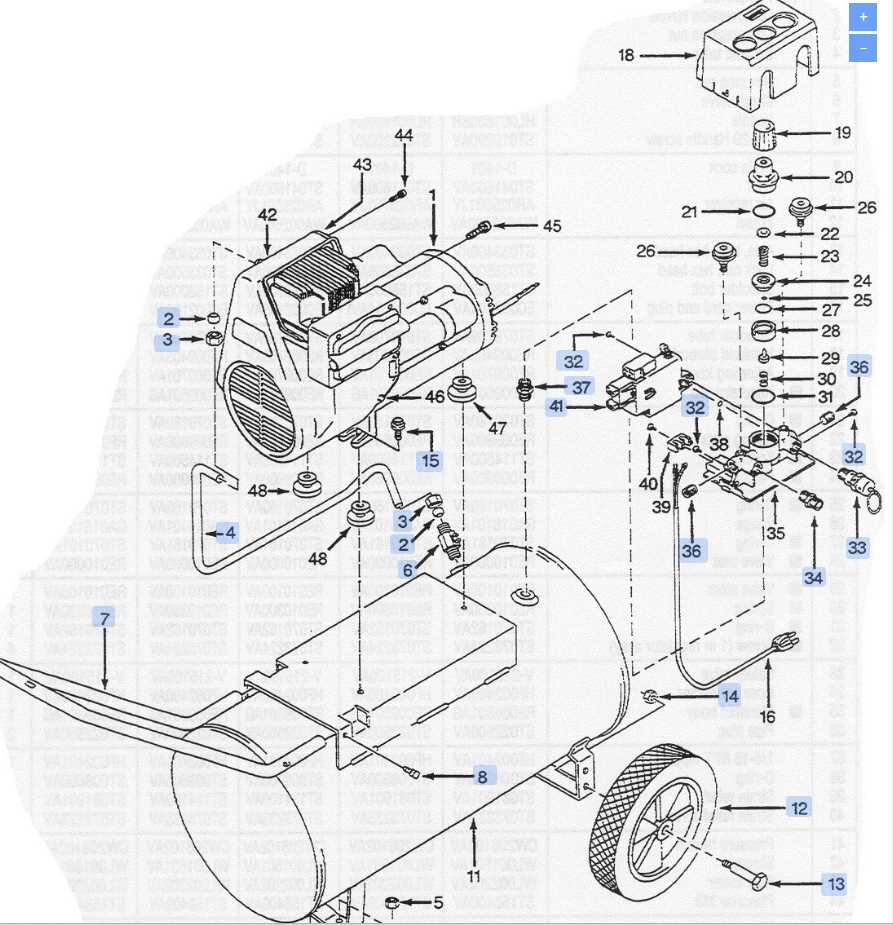

When exploring the intricacies of these systems, visual representations become invaluable. Diagrams that outline the configuration and relationships between various components serve as essential guides for both novice users and experienced technicians. Such illustrations can illuminate complex designs, making it easier to understand how each piece fits into the larger machinery.

Additionally, being familiar with the specific terminology associated with these elements can significantly enhance one’s ability to communicate effectively about maintenance and repair. Understanding the function of each section empowers users to take informed actions, ensuring longevity and optimal operation. This knowledge can transform routine upkeep into a more intuitive process.

Understanding Campbell Hausfeld Air Compressors

The machines designed for providing pressurized gas have become essential tools in various industries and workshops. Their functionality hinges on a variety of components working harmoniously to achieve optimal performance. Gaining insight into these devices helps users make informed decisions about maintenance and upgrades.

At the core of these devices is a mechanism that converts electrical energy into kinetic energy, allowing for an efficient transfer of force. This transformation is crucial for tasks ranging from powering pneumatic tools to inflating tires. Understanding the individual elements involved in this process is key to maximizing efficiency and lifespan.

Regular maintenance is vital to ensure these machines operate smoothly. Key aspects include checking seals, monitoring pressure levels, and ensuring that filters are clean. By paying attention to these details, users can prevent common issues that lead to breakdowns or decreased performance.

Moreover, knowing how to identify and troubleshoot potential problems can save time and resources. Familiarity with the various components empowers users to handle minor repairs independently, thereby enhancing productivity and reducing downtime.

In conclusion, a comprehensive understanding of these pressure-generating devices is invaluable. It not only aids in effective usage but also enhances the overall longevity of the equipment, making it a worthwhile investment for any professional or hobbyist.

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial for effective maintenance and repair processes. These illustrations serve as vital tools that guide users in understanding the intricate relationships between various elements within a system. By providing clarity, they significantly enhance the overall efficiency of troubleshooting and assembly.

When individuals rely on accurate schematics, they can quickly identify the correct components needed for repairs, reducing the likelihood of errors. Clear illustrations allow users to visualize the positioning and function of each element, making it easier to comprehend complex mechanisms. This understanding minimizes the chances of misinterpretation, leading to more successful outcomes.

Moreover, well-crafted visuals contribute to the longevity of equipment. Properly executed repairs, informed by accurate representations, ensure that systems function optimally over time. This not only enhances performance but also reduces maintenance costs, as informed users are less likely to encounter recurring issues due to oversight.

In summary, the significance of precise component illustrations cannot be overstated. They are essential for efficient repairs, user comprehension, and long-term equipment reliability. Emphasizing the need for accuracy in these resources ultimately benefits both the user and the machinery involved.

Common Components of Air Compressors

Understanding the essential elements of pressure generating devices is crucial for their effective operation and maintenance. These systems comprise various components that work together to convert power into stored energy, enabling a range of applications from powering tools to inflating tires.

Key Elements

At the core of these systems lies the motor, which serves as the driving force, converting electrical or fuel energy into mechanical energy. Connected to the motor is the pump, responsible for compressing the gas and increasing its pressure. Additionally, a receiver tank stores the compressed gas, allowing for a steady supply during operation.

Supporting Features

Other notable components include pressure switches, which regulate the pressure levels, and filters that ensure the gas remains clean and free of contaminants. Moreover, hoses and fittings facilitate the transfer of compressed gas to various tools, making these systems versatile in their applications.

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repair tasks. These visual guides provide a comprehensive view of components, their arrangement, and how they interact. Familiarizing oneself with this type of documentation can greatly enhance your ability to troubleshoot and replace parts accurately.

Key Elements of an Assembly Illustration

When examining an assembly illustration, several critical elements should be noted:

| Element | Description |

|---|---|

| Labels | Typically include part numbers and descriptions, which help in identifying each component. |

| Connections | Arrows or lines that indicate how parts are interconnected or interact with each other. |

| Legends | Key to understanding symbols and color codes used within the illustration. |

| Views | Different perspectives may be shown, such as top, side, or exploded views, providing clarity on complex assemblies. |

Steps to Effectively Utilize an Assembly Illustration

To make the most of an assembly illustration, follow these steps:

- Identify the specific component you need by locating its label.

- Examine the connections to understand how the component integrates with others.

- Refer to the legend to clarify any unfamiliar symbols or colors.

- Use multiple views to gain a comprehensive understanding of the assembly.

Identifying Replacement Parts Easily

When it comes to maintaining equipment, knowing how to find the right components is crucial for seamless operation. Identifying the necessary items can save both time and money, ensuring that your machinery runs efficiently. This section will provide insights on how to navigate the process of locating specific elements for your equipment.

Understanding the anatomy of your device is the first step. Familiarize yourself with its structure and functions. This knowledge will empower you to recognize worn or damaged components that need replacement.

| Component Type | Common Signs of Wear | Replacement Options |

|---|---|---|

| Seals | Leaks, decreased pressure | OEM, aftermarket alternatives |

| Filters | Reduced airflow, contamination | Original, compatible brands |

| Pistons | Noisy operation, loss of power | Standard, high-performance models |

| Valves | Irregular operation, hissing sounds | Direct replacements, upgrades |

Utilizing manuals or online resources can further assist in pinpointing the right items. Detailed documentation often includes helpful illustrations and part numbers that simplify your search. Additionally, connecting with communities or forums dedicated to similar machinery can provide valuable recommendations and experiences shared by others.

Maintenance Tips for Air Compressors

Regular upkeep is essential for ensuring optimal performance and longevity of your pneumatic equipment. Implementing a consistent maintenance routine can prevent breakdowns, enhance efficiency, and save on repair costs. Below are some effective strategies to keep your machinery in top condition.

Routine Checks

Establish a schedule for regular inspections to identify potential issues early. Pay attention to the following aspects:

| Component | Check Frequency | Recommended Action |

|---|---|---|

| Oil Level | Weekly | Top up or replace as needed |

| Filters | Monthly | Clean or replace when dirty |

| Hoses and Connections | Monthly | Inspect for wear and leaks |

| Belt Tension | Every 3 Months | Adjust or replace as necessary |

| Safety Valves | Every 6 Months | Test for proper operation |

Cleaning and Lubrication

Maintaining cleanliness and proper lubrication is crucial for performance. Remove dust and debris regularly, and ensure moving parts are adequately lubricated to minimize friction and wear.

Where to Find Genuine Parts

Locating authentic components for your equipment can be crucial for maintaining performance and longevity. Ensuring that you acquire the right items not only enhances functionality but also safeguards against potential damage caused by inferior alternatives. Here are some effective avenues to explore.

Official Manufacturer Sources

- Visit the manufacturer’s official website to access their online store.

- Contact customer service for recommendations on authorized dealers.

- Look for warranty information that may include details on where to purchase genuine items.

Authorized Retailers and Distributors

- Research local hardware stores known for carrying quality brands.

- Check online marketplaces that partner with reputable suppliers.

- Inquire about any local distributors who specialize in your specific equipment line.

By exploring these options, you can ensure that you find reliable components that meet the necessary standards for your machinery.

Common Issues and Solutions

When operating machinery designed for pressurized tasks, users often encounter a range of challenges. Understanding these common problems and their solutions can greatly enhance efficiency and longevity.

- Insufficient Pressure:

- Check for leaks in hoses and connections.

- Inspect the pressure switch settings.

- Ensure that the intake filter is clean and unobstructed.

- Excessive Noise:

- Examine for loose components or fasteners.

- Lubricate moving parts as necessary.

- Consider replacing worn-out bearings or seals.

- Overheating:

- Verify that the cooling system is functioning properly.

- Keep the unit in a well-ventilated area.

- Reduce workload or duty cycle if consistently overheated.

- Vibration:

- Check for imbalanced or misaligned components.

- Ensure the equipment is placed on a stable, level surface.

- Inspect the mounting hardware for any signs of wear.

- Inconsistent Performance:

- Review the maintenance schedule and follow recommended practices.

- Replace worn or damaged parts immediately.

- Calibrate settings according to the manufacturer’s specifications.

Addressing these common issues promptly can prevent further complications and maintain optimal functionality of your equipment.

Upgrading Your Air Compressor System

Enhancing your pneumatic system can significantly improve its efficiency and performance. By investing in advanced components and technologies, you can achieve better power output, reduced noise levels, and increased longevity. This section will explore various strategies for optimizing your setup.

One effective way to elevate performance is by upgrading the motor to a more powerful or energy-efficient model. This can provide a substantial boost in capability, allowing you to handle more demanding tasks with ease. Additionally, consider replacing outdated valves and regulators with modern, precision-engineered alternatives that offer improved flow rates and control.

Furthermore, implementing better filtration systems can enhance the quality of the air, reducing wear on internal mechanisms and extending the lifespan of your equipment. Regular maintenance and timely replacements of key elements, such as seals and gaskets, are also essential for maintaining optimal functionality.

Finally, evaluating your existing storage solutions and expanding your reservoir can lead to increased output and reduced cycle times. Investing in these upgrades not only enhances performance but can also save you money in the long run by minimizing energy consumption and maintenance costs.