The efficiency of modern vehicles relies on a variety of systems working seamlessly together. Among these, one crucial unit ensures that driving in hot weather remains comfortable. This intricate mechanism is responsible for regulating the flow of air, transforming the interior climate into a controlled and pleasant environment.

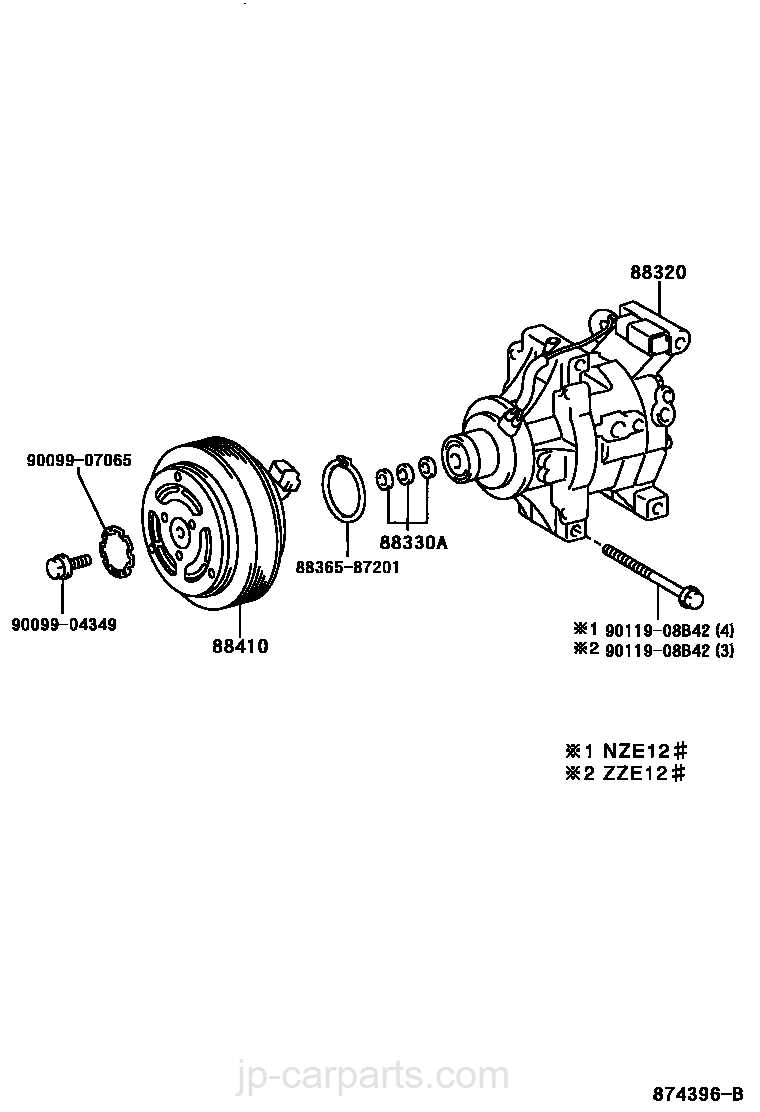

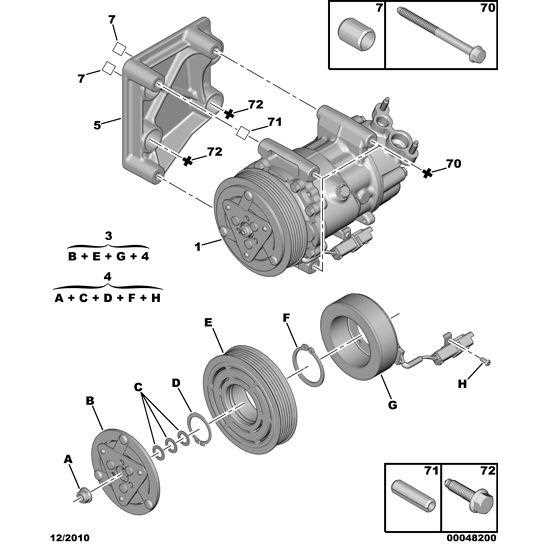

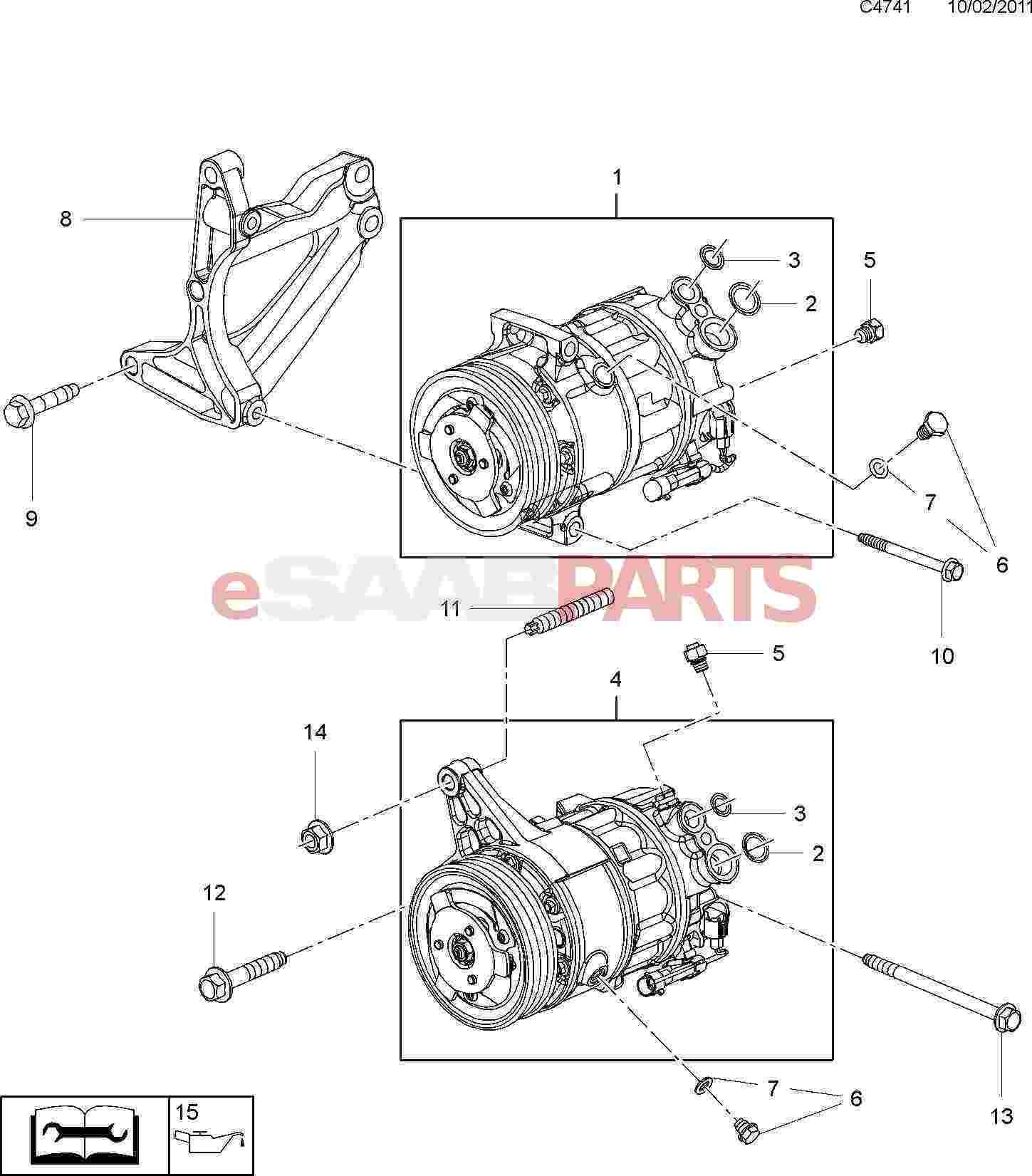

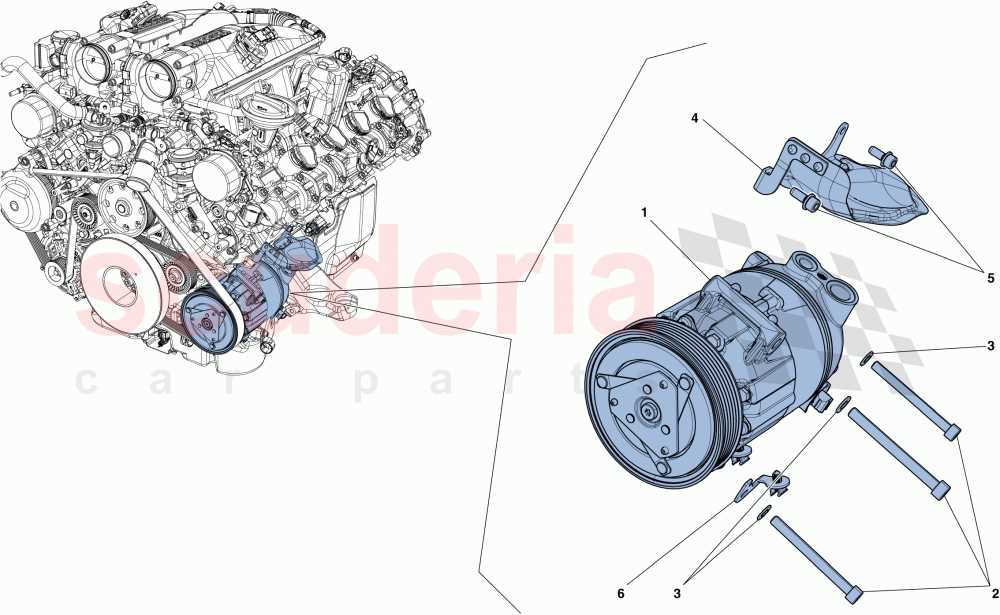

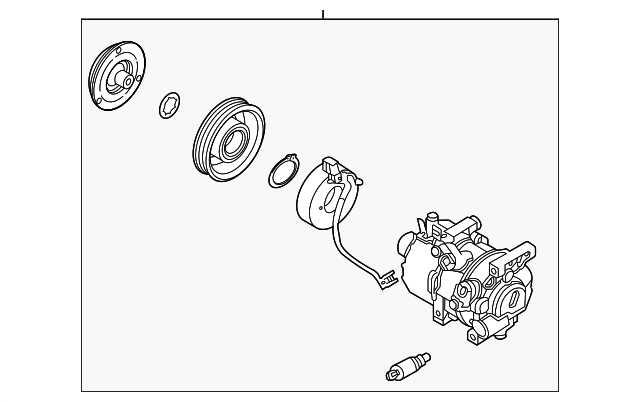

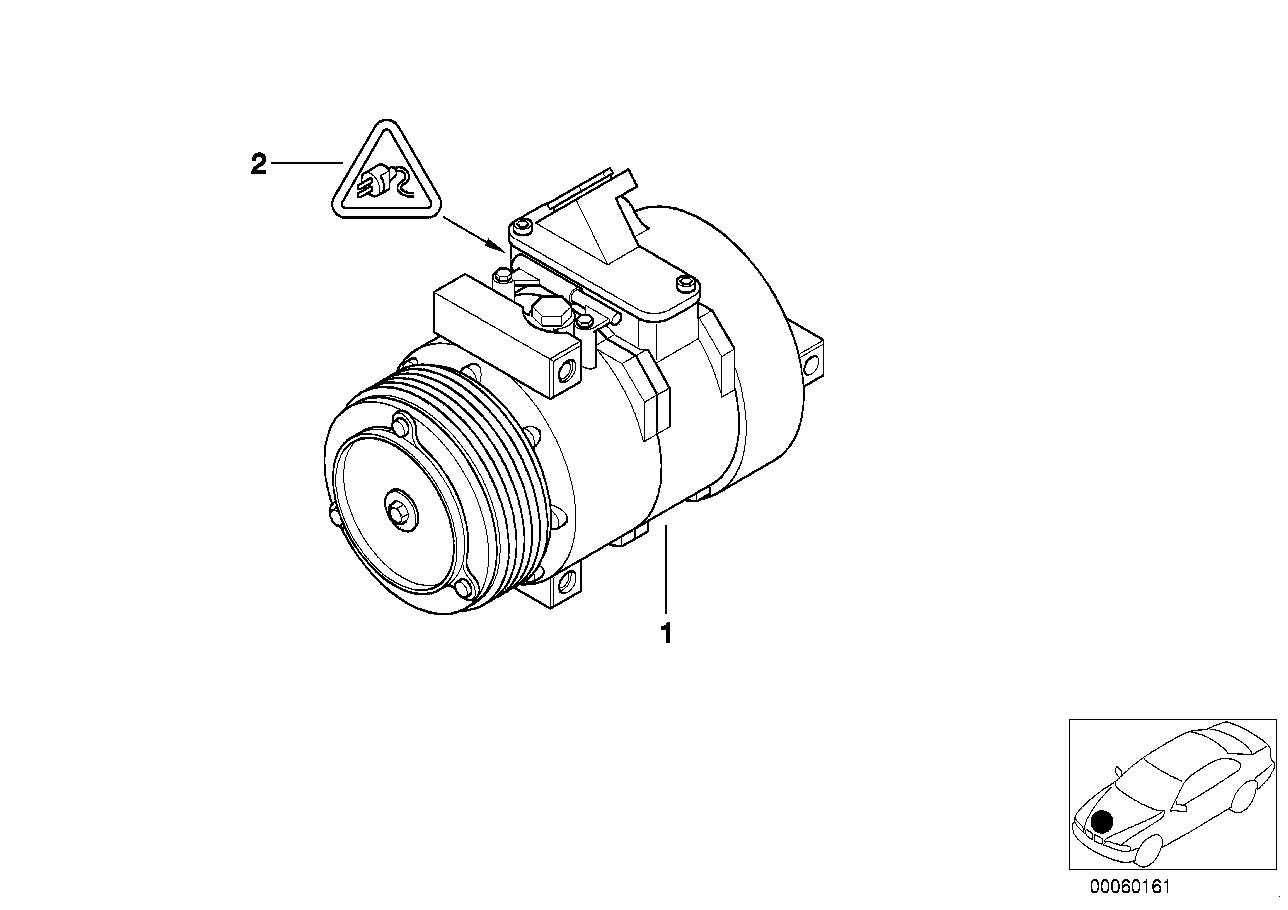

Inside this unit, several key elements interact to fulfill their role in the overall operation. Each component is meticulously designed to perform a specific function, contributing to the smooth and efficient circulation of air. Understanding how these elements are arranged and connected is essential for both maintenance and troubleshooting.

This guide delves into the specifics of this system, providing a clear and detailed view of its structural design. Whether you’re a professional or an enthusiast, exploring the technical layout of this system will enhance your understanding of its operation and help ensure optimal performance.

Understanding the Role of an AC Compressor

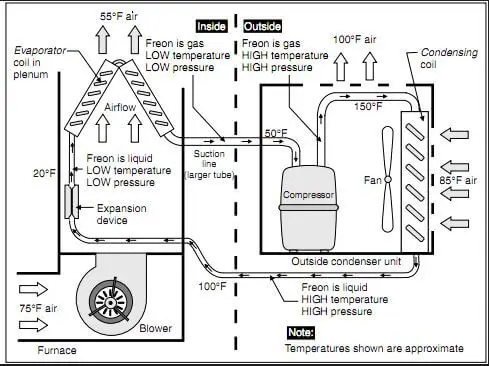

At the heart of any cooling system lies a key component responsible for regulating temperature by cycling refrigerant. This essential device works by transforming gas into a liquid state, facilitating the movement of cooled air throughout the system. The importance of this mechanism becomes evident in how it ensures consistent thermal regulation, especially in environments with fluctuating temperatures.

| Function | Description |

|---|---|

| Refrigerant Circulation | It propels the cooling fluid through the system, ensuring efficient heat exchange. |

| Pressure Management | By adjusting the state of the refrigerant, it maintains the pressure levels necessary for cooling. |

| Temperature Control | It contributes to the overall air conditioning process by regulating the flow of refrigerant, which cools the air. |

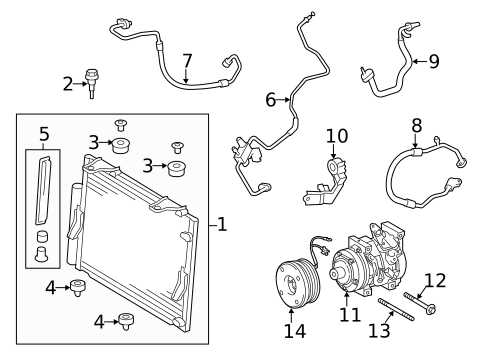

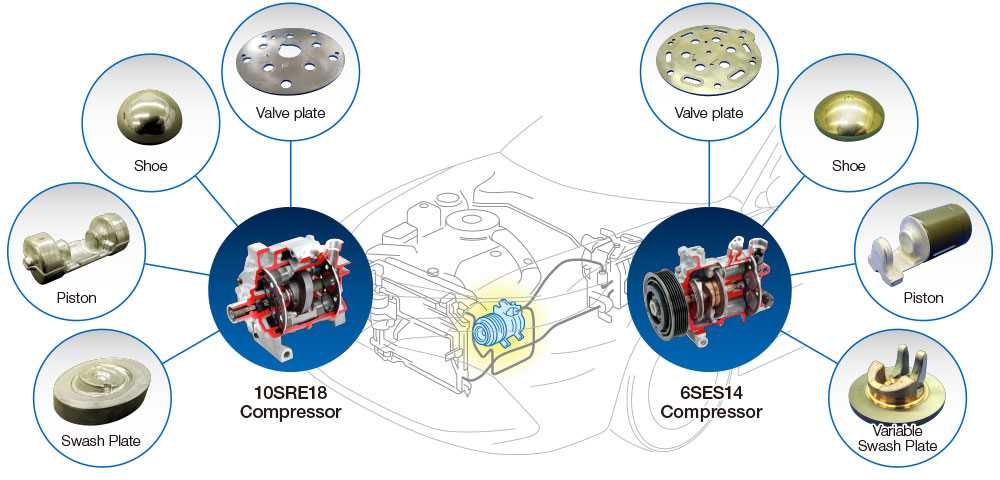

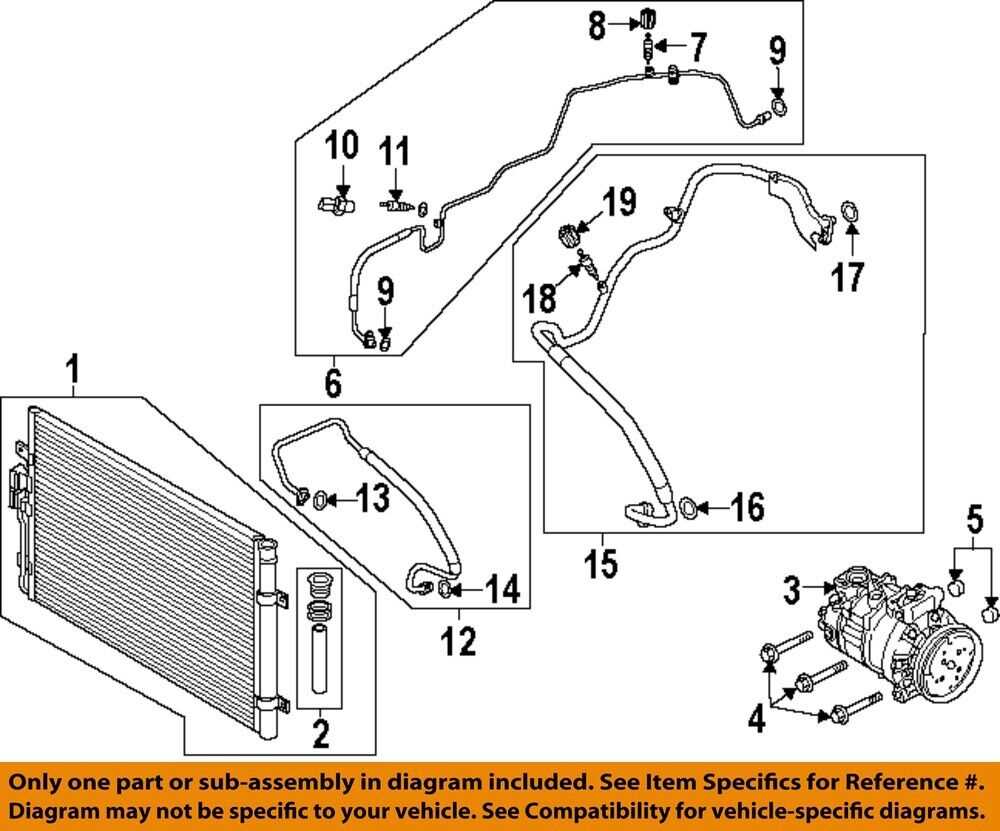

Main Components in an Air Conditioning Unit

An air conditioning system relies on the interaction of several critical elements to deliver cooling and comfort to a space. These elements work in harmony to regulate temperature and humidity, ensuring an efficient transfer of heat from inside the room to the external environment. Understanding how these key components function together is essential to grasp the overall operation of the system.

Heat Transfer Mechanism

At the core of any cooling system is the method of heat exchange. The unit pulls in warm air from the interior, absorbs the heat, and releases it outdoors, allowing the cooler air to circulate back into the room. This process is facilitated by a series of elements responsible for moving air and refrigerant through the system, ensuring continuous heat removal and cooling.

Refrigerant Circulation

One of the most important factors in this system is the substance that moves through the cooling unit. This chemical agent undergoes phase changes, absorbing and releasing heat as it cycles through various stages. The efficiency of this circulation is maintained by the coordination of several moving and stationary parts, each contributing to the smooth operation of the unit.

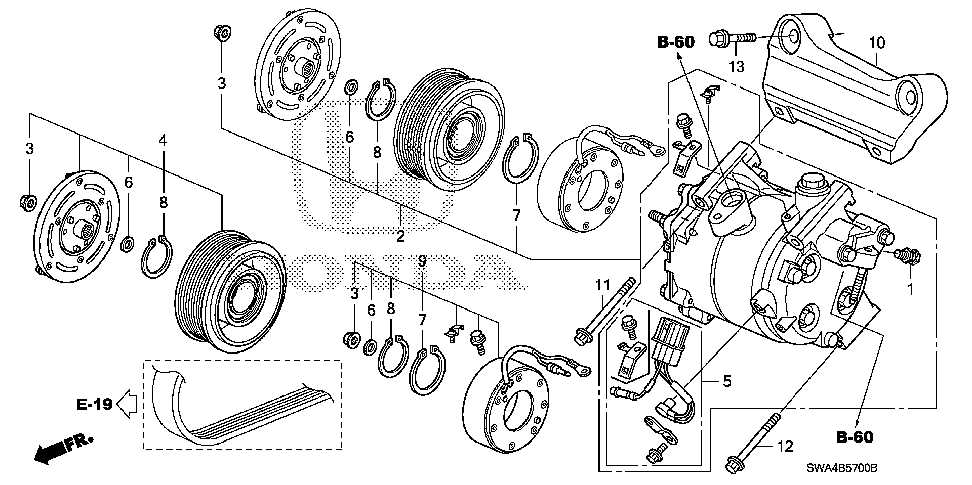

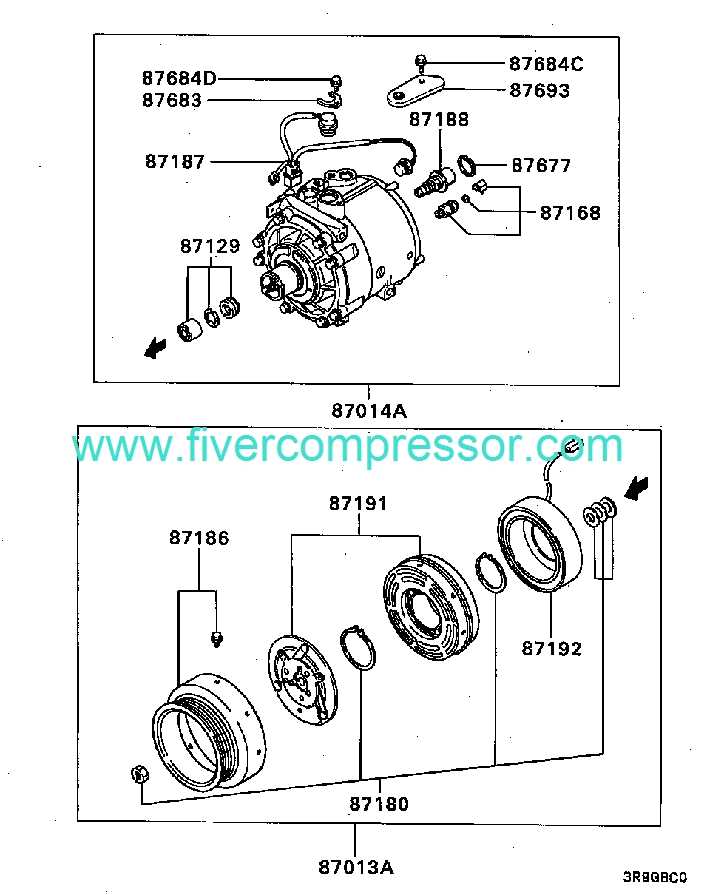

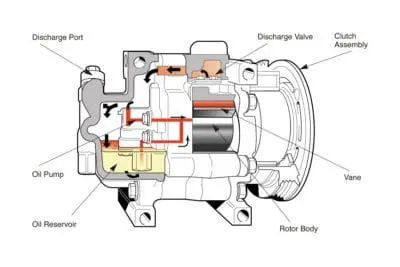

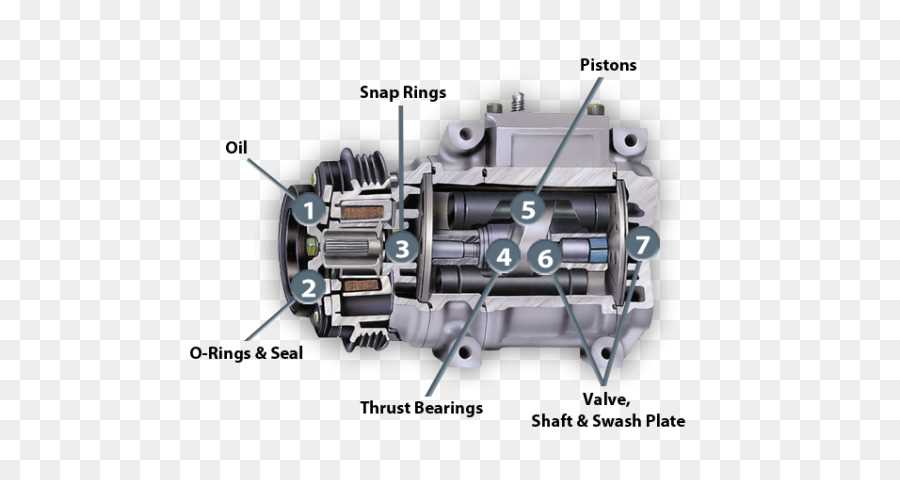

Functionality of Valves and Seals in Compressors

The performance and efficiency of mechanical systems often depend on the interaction of various internal elements. Two critical components that ensure smooth operation are the valves and seals. These elements work together to regulate fluid flow and maintain system integrity, playing a key role in maintaining the proper balance of forces inside the unit.

The Role of Valves

Valves are responsible for controlling the movement of gases or liquids through the system. By opening and closing at precise intervals, they allow the required flow while preventing backflow. This function is essential for maintaining pressure and ensuring the system operates at its optimal efficiency. Depending on the design, these elements may vary in complexity but always aim to enhance reliability.

Importance of Seals

Seals, on the other hand, are designed to prevent leaks and protect the internal environment from external contaminants. They create a secure boundary that keeps fluids contained within specific chambers, thereby preventing loss of efficiency and ensuring the system operates as intended. High-quality seals are vital for ensuring longevity and reducing wear on other components.

Common Materials Used in Compressor Construction

In any machinery, the choice of materials plays a critical role in ensuring durability, efficiency, and performance. Various components require specific material properties to handle the pressures and temperatures they are exposed to. Understanding the typical materials used allows for a deeper appreciation of the engineering behind these systems.

Metals for Strength and Durability

- Aluminum: Lightweight and resistant to corrosion, commonly used for housing and other external elements.

- Steel: Known for its strength and ability to withstand high pressure, often applied in internal mechanical structures.

- Copper: Excellent for heat transfer and electrical conductivity, frequently found in critical thermal and conductive areas.

Non-Metallic Components

- Plastics: Certain polymers are chosen for seals, gaskets, and insulation due to their flexibility and resistance to wear.

- Ceramics: Used in specific

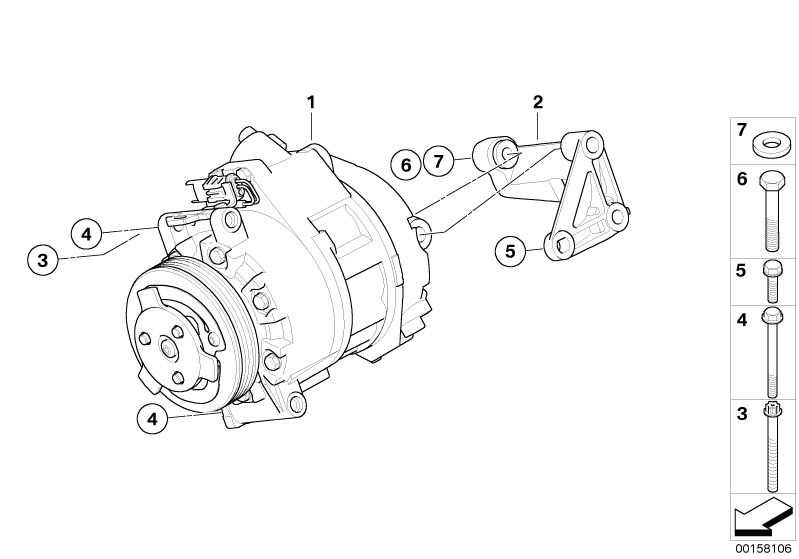

How Bearings Support Compressor Operation

Bearings play a crucial role in the functionality of various machines by ensuring smooth and efficient motion. Their design allows for reduced friction between moving elements, enabling systems to operate with greater precision and longevity. These components are particularly important in mechanisms where continuous, high-speed movement is required, as they help maintain stability and balance.

Types of Bearings Commonly Used

Different systems rely on various types of bearings, each designed to handle specific loads and conditions. For example, ball bearings are often employed to manage rotational motion and minimize wear, while roller bearings are better suited for heavier loads. The selection of the correct bearing type significantly influences the performance and durability of the system.

Key Functions of Bearings

Function Description Reducing Friction Minimizes resistance between moving parts, ensuring smooth operation and reducing energy loss. Supporting Rotational Motion Allows shafts Exploring the Use of Pistons and Cylinders

Pistons and cylinders are integral components found in various mechanical systems, serving critical roles in converting energy into motion. These elements work together to facilitate efficient operation, ensuring optimal performance in their respective applications. Understanding their function and design can provide insights into the mechanics behind energy transformation.

Functionality of Pistons

The piston serves as a vital component that moves within the cylinder. Its primary responsibilities include:

- Creating pressure through linear motion.

- Enabling the transfer of energy through mechanical means.

- Assisting in the intake and expulsion of gases or fluids during cycles.

Role of Cylinders

Cylinders provide the housing for pistons, ensuring smooth movement and containment of forces. Their significance lies in:

- Facilitating the controlled environment for pressure buildup.

- Providing structural integrity and support during operation.

- Minimizing friction to enhance efficiency and longevity.

In summary, the collaboration between pistons and cylinders is essential for achieving high performance and efficiency in numerous applications. Their design and functionality play a crucial role in mechanical systems, driving innovation and effectiveness in energy conversion processes.

Refrigerant Flow Regulation in Compressors

Effective management of refrigerant circulation is essential for the efficient operation of cooling systems. The control of this fluid’s movement plays a pivotal role in maintaining optimal temperature levels, ensuring energy efficiency, and enhancing overall system performance. Various mechanisms and components contribute to the regulation of this flow, each serving a specific function in the refrigeration cycle.

Key Components in Flow Regulation

- Expansion Devices: These components modulate the refrigerant’s pressure and flow rate, allowing for a precise adjustment based on system demands.

- Flow Control Valves: They adjust the volume of refrigerant entering the evaporator, maintaining the balance between supply and demand.

- Sensors and Thermostats: These instruments monitor temperature and pressure, providing feedback to the control system for efficient operation.

Methods of Flow Control

- Mechanical Regulation: Utilizes physical components to restrict or allow refrigerant flow based on system needs.

- Electronic Control: Involves the use of electronic sensors and actuators for more precise and responsive flow management.

- Variable Speed Drives: Adjust the speed of circulation devices to match the cooling demand, optimizing energy consumption.

Understanding these aspects of refrigerant circulation not only helps in optimizing cooling efficiency but also extends the lifespan of the entire system. Proper flow regulation ensures that each component operates under ideal conditions, reducing wear and enhancing reliability.

Maintenance Tips for Extending Compressor Life

To ensure the longevity of your cooling unit, it’s essential to implement a consistent maintenance routine. Regular care not only enhances performance but also prevents unexpected breakdowns and costly repairs. By following a few simple practices, you can significantly extend the operational lifespan of your system.

First, keep the surroundings clean and free from debris. Dust and dirt accumulation can obstruct airflow, leading to overheating and reduced efficiency. Regularly inspect and clean the exterior, ensuring that ventilation openings remain unobstructed.

Next, check and replace filters as needed. Clogged filters can restrict airflow, forcing the system to work harder, which may lead to premature wear. Adhering to a replacement schedule will help maintain optimal performance.

Additionally, ensure that the refrigerant levels are appropriate. Low refrigerant can indicate a leak, which can severely impact functionality. Regularly monitor levels and consult a professional for recharging or repairs when necessary.

Lastly, schedule routine professional inspections. Technicians can identify potential issues before they escalate and recommend necessary adjustments. By prioritizing regular maintenance, you enhance efficiency and prolong the life of your cooling unit.

Signs of Wear and Replacement Parts Overview

Identifying the need for new components in a cooling system is crucial for maintaining efficiency and functionality. Various indicators can signal that certain elements are no longer performing optimally. Regular inspection and understanding these signs can help in preventing further damage and ensuring a smooth operation.

Common Indicators of Deterioration

- Unusual Noises: Sounds such as grinding, rattling, or hissing may suggest issues with internal mechanisms.

- Reduced Efficiency: Noticeable declines in cooling performance can indicate that certain elements are failing.

- Leaks: Fluid leaks around the unit are a strong sign of wear, often pointing to seal deterioration.

- Increased Energy Consumption: A sudden spike in energy bills may be a result of malfunctioning components working harder than usual.

Replacement Options

When signs of wear become evident, timely replacement is essential. Below are common options available:

- Rebuild kits: Often include essential items for restoring function.

- Seals and gaskets: Key for preventing leaks and maintaining efficiency.

- Electrical components: Including relays and sensors that ensure proper operation.

- Fan assemblies: Vital for adequate airflow and heat exchange.

Choosing high-quality replacements can enhance reliability and extend the lifespan of the entire system. Regular maintenance and timely updates are vital for optimal performance.