When it comes to maximizing efficiency and precision in your woodworking projects, a thorough understanding of your equipment is essential. Familiarizing yourself with the various elements that constitute your machine not only enhances its performance but also extends its lifespan. Knowing how each segment functions and interconnects can empower you to tackle maintenance and repairs with confidence.

In this section, we will explore the intricate layout of a commonly used woodworking instrument, breaking down its critical components. This knowledge can be particularly beneficial for hobbyists and professionals alike, allowing for a smoother workflow and reducing the likelihood of unexpected disruptions during your projects. By delving into the specifics, you can ensure that your tool operates at its best, ultimately leading to superior results.

Whether you are assembling a new unit or troubleshooting an existing one, understanding the organization of each piece can make the process significantly easier. We will provide insights that will help you navigate through the various sections and understand their roles. This foundational knowledge is key to becoming more adept at using and caring for your machinery.

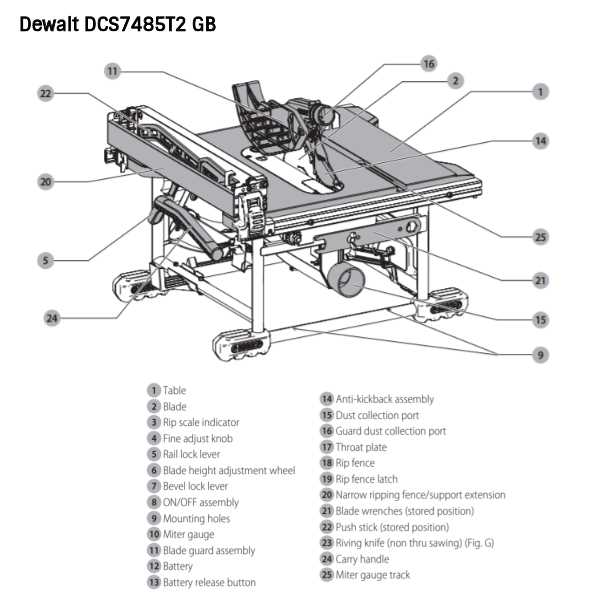

Dewalt Table Saw Overview

This section provides a comprehensive look at a leading tool designed for precision cutting and efficiency in various woodworking projects. Renowned for its robust construction and user-friendly features, this equipment caters to both professionals and hobbyists alike, making it an essential asset in any workshop.

Key Features

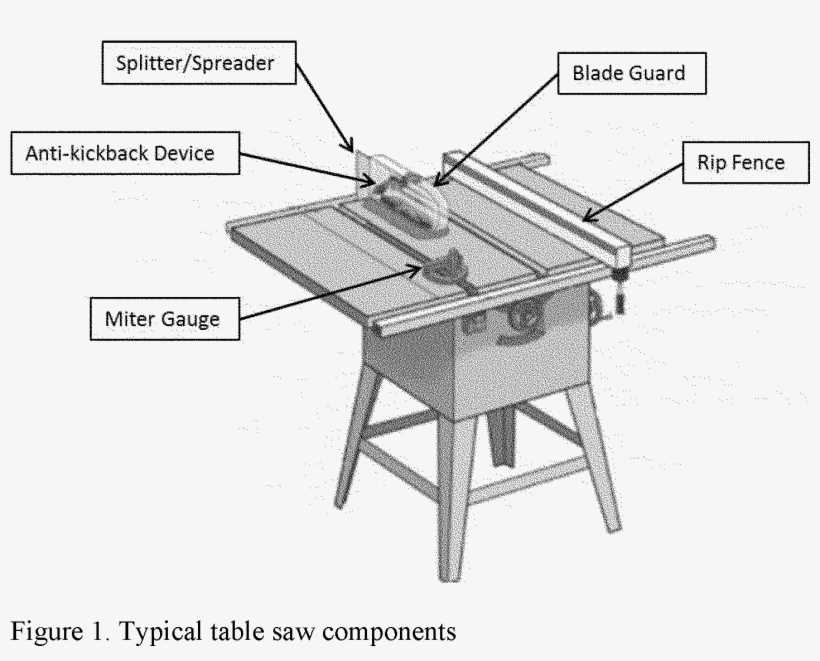

The tool is equipped with a powerful motor that ensures smooth operation and reliable performance. It often includes an adjustable blade height and angle settings, allowing for versatile cutting options. Safety features, such as blade guards and anti-kickback mechanisms, enhance user protection, promoting a secure working environment.

Applications

Key Components of Dewalt Saws

Understanding the essential elements of these power tools is crucial for both effective operation and maintenance. Each component plays a significant role in ensuring optimal performance, reliability, and safety during use. Familiarity with these elements can enhance the user experience and extend the tool’s lifespan.

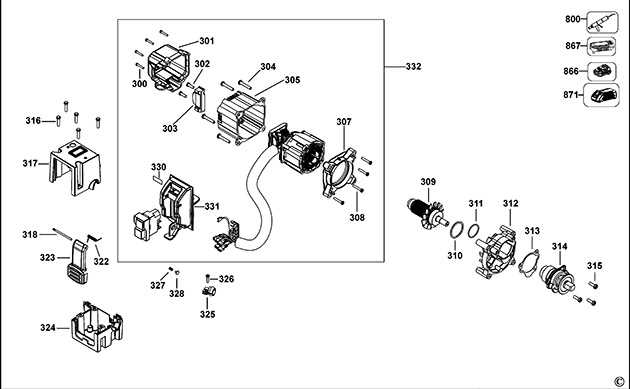

Motor: The heart of any cutting device, the motor provides the necessary power to perform tasks efficiently. A robust motor ensures that the tool can handle various materials without compromising on speed or precision.

Blade: The cutting edge is critical for achieving clean and accurate cuts. Different blade types are available to accommodate various applications, from fine woodworking to heavy-duty projects. Choosing the right blade can significantly impact the quality of work.

Table Surface: A flat and stable work surface is vital for precision cutting. It supports the material being worked on and helps maintain alignment during operations, thereby reducing the risk of errors.

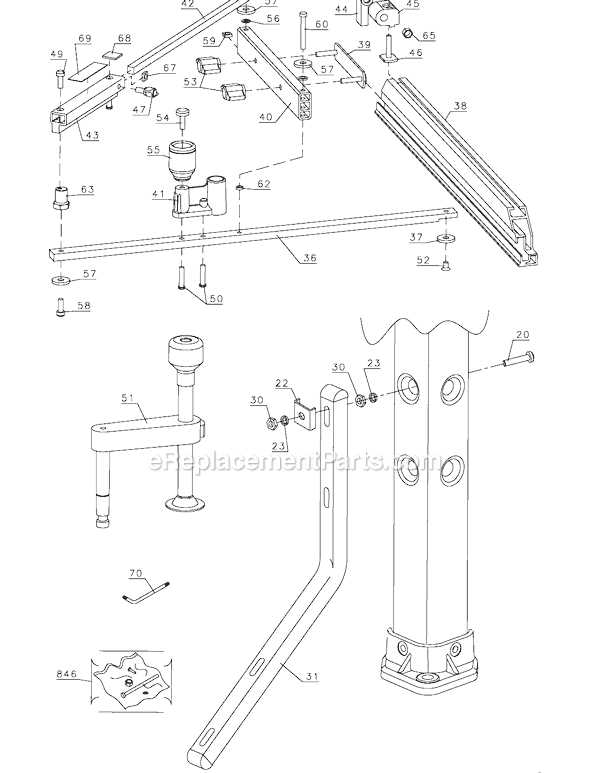

Fence: This adjustable guide allows for accurate and consistent cuts. A high-quality fence will minimize the chances of deviation, ensuring that every cut is precise and meets the intended measurements.

Safety Features: These tools often come equipped with various safety mechanisms, such as blade guards and emergency shut-off switches. Understanding and utilizing these features is essential for protecting the user from potential accidents.

By familiarizing oneself with these key components, users can maximize the efficiency and safety of their cutting tools, leading to better results in their projects.

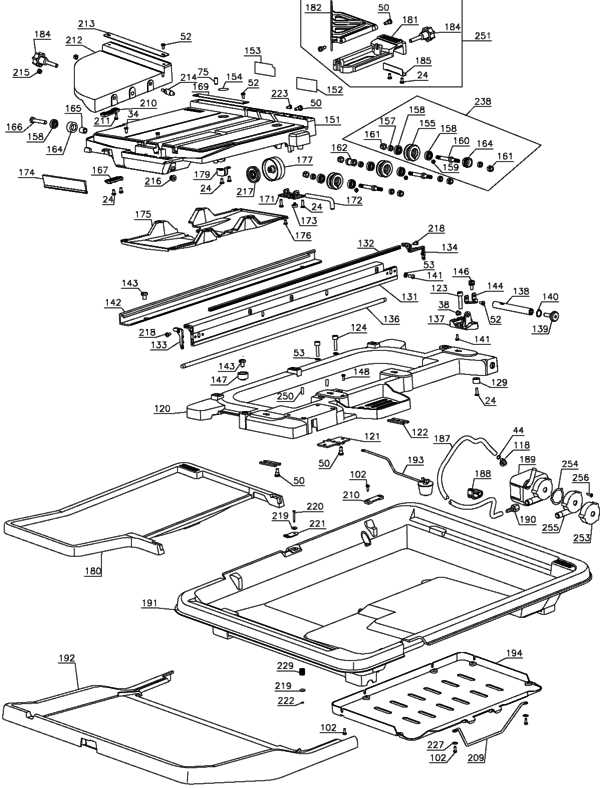

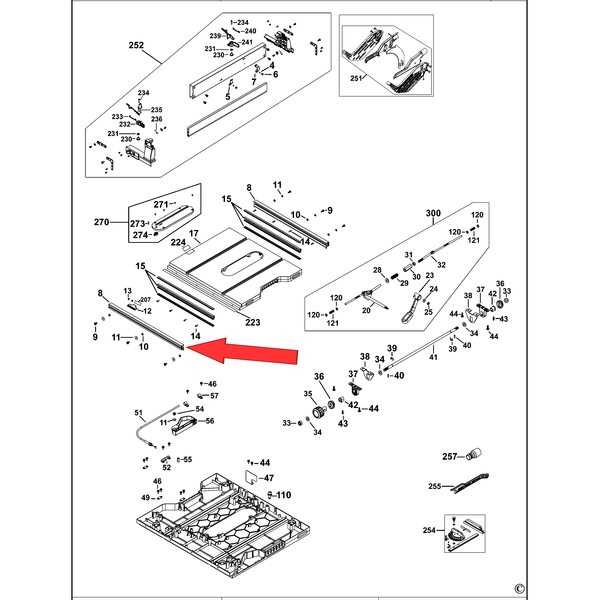

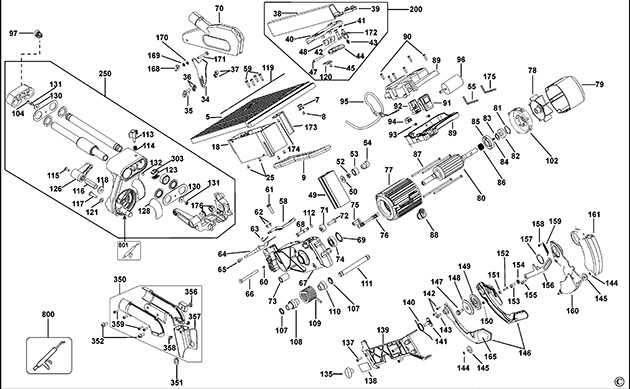

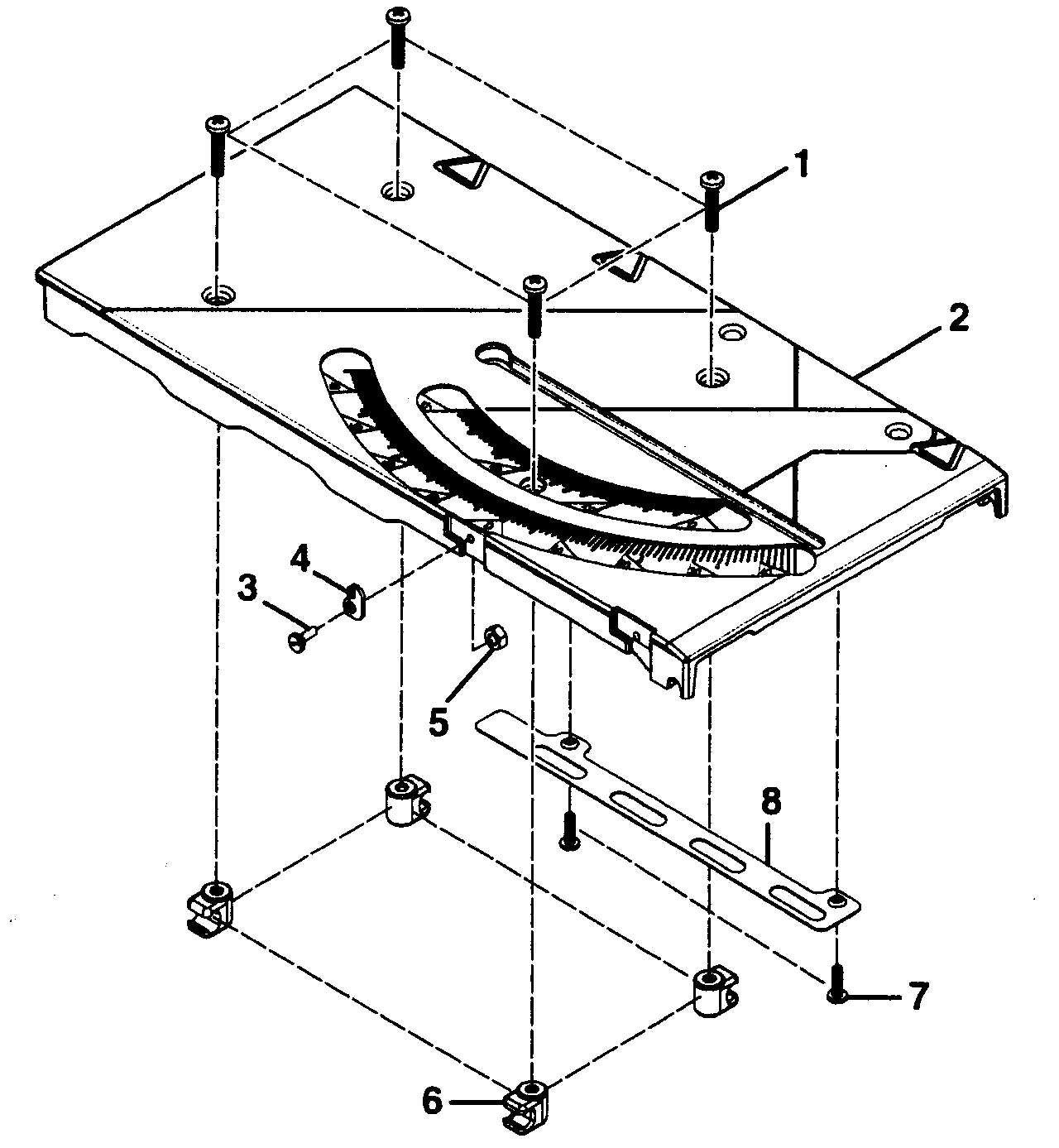

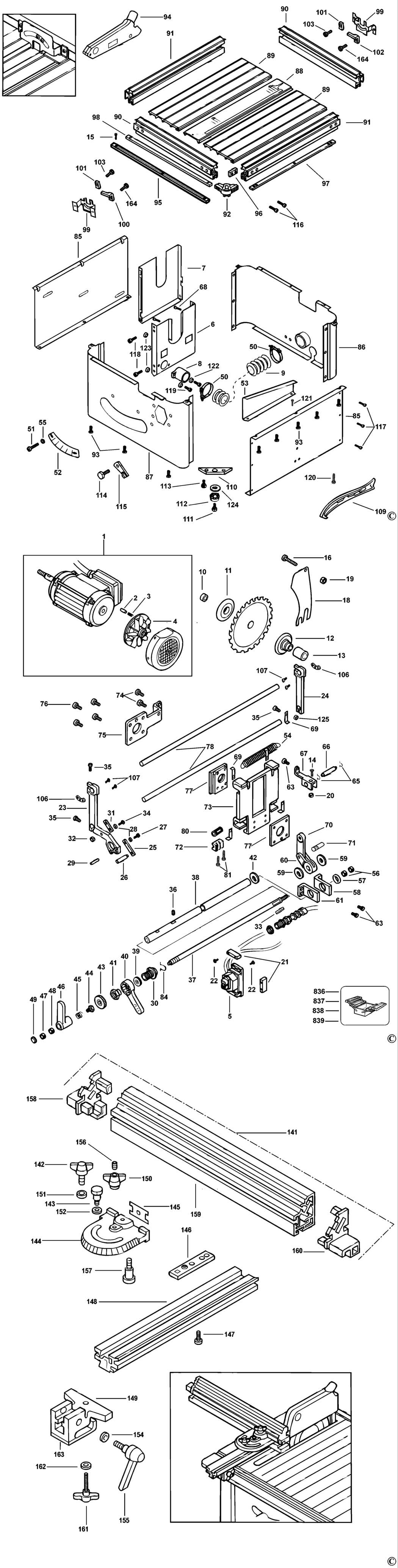

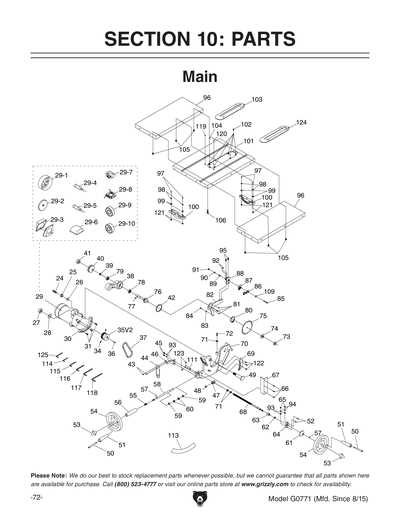

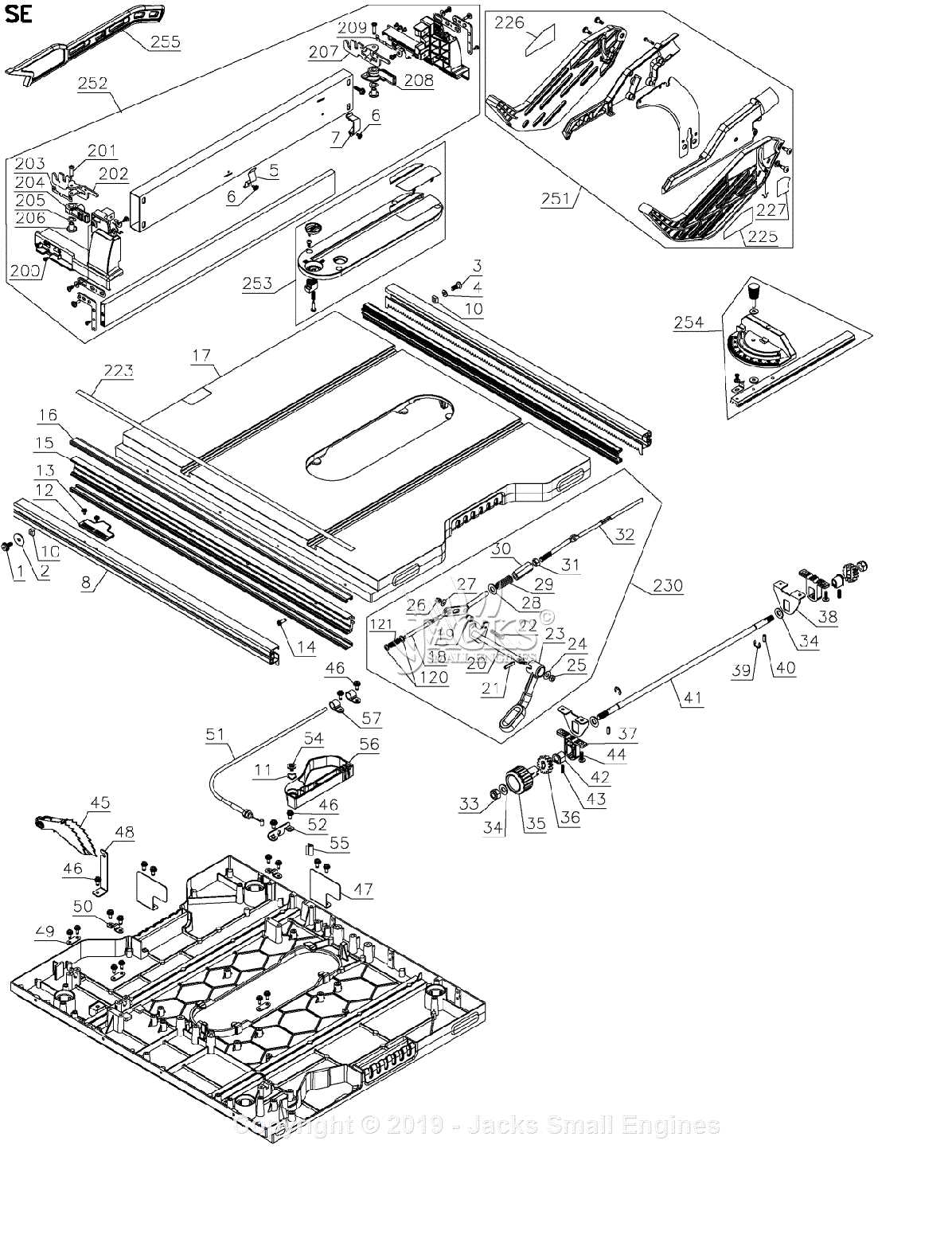

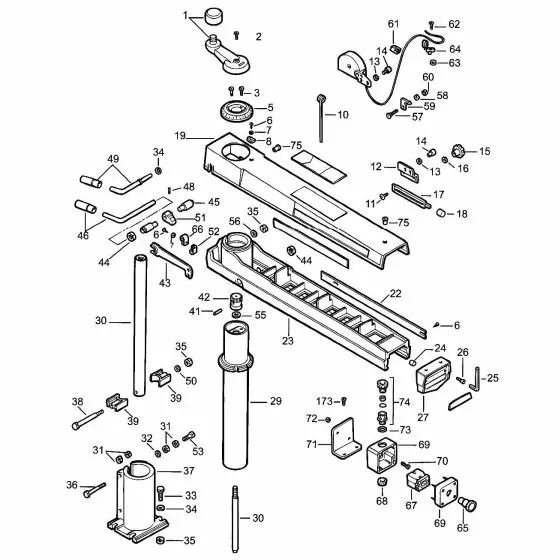

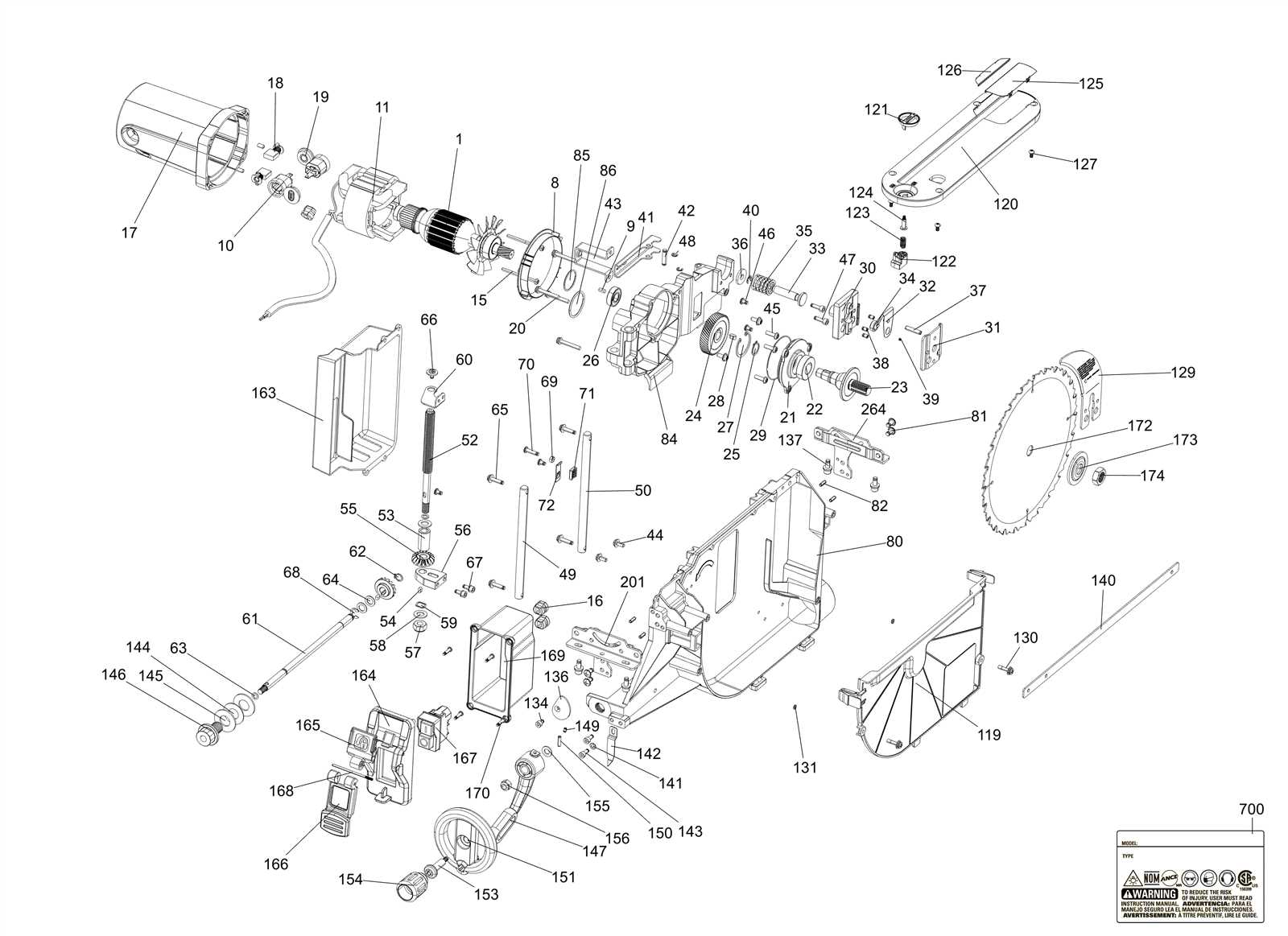

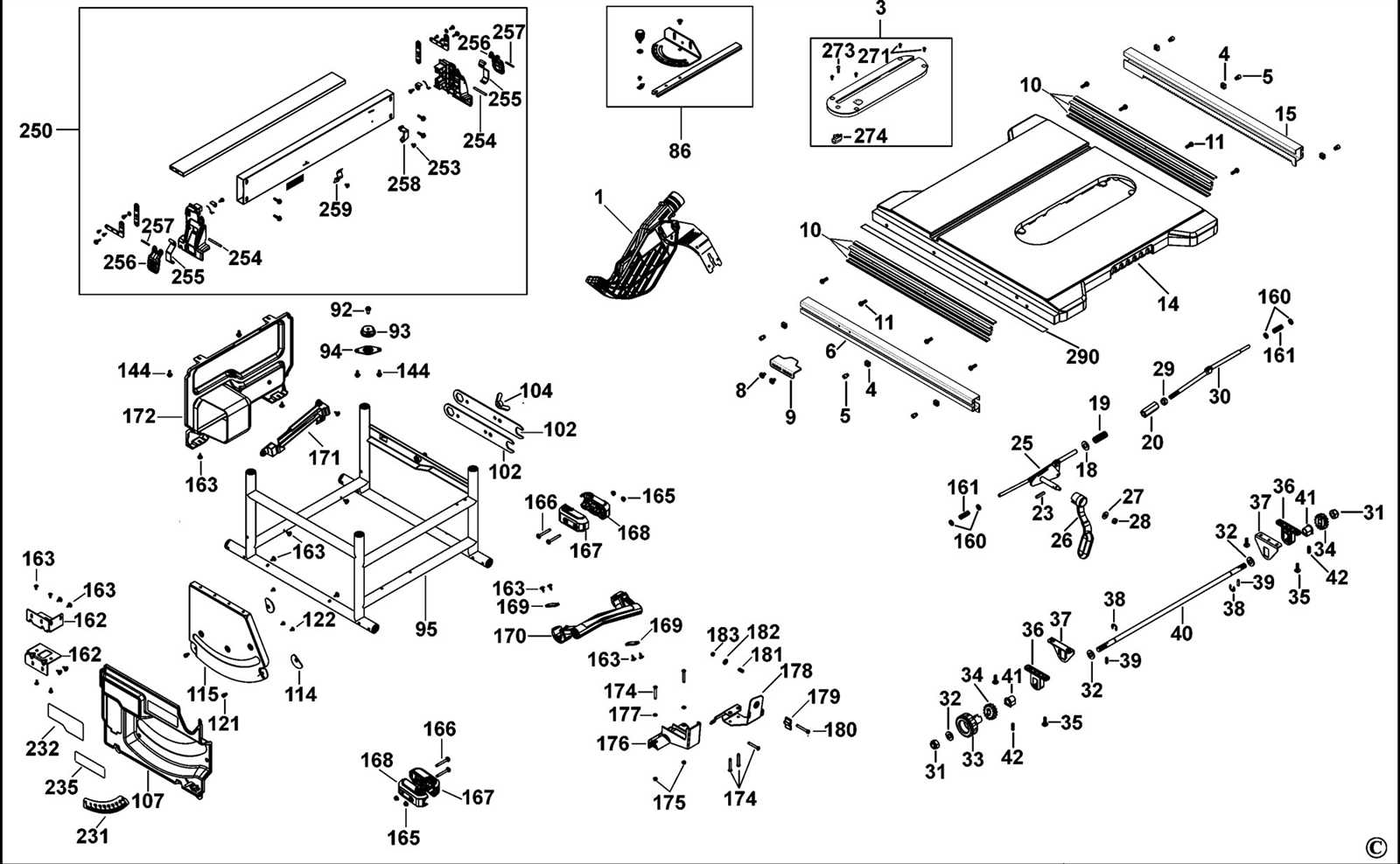

Understanding the Parts Diagram

Comprehending the schematic representation of a tool is essential for efficient maintenance and troubleshooting. This visual guide highlights the components, enabling users to identify and understand the function of each element within the machinery. Mastery of this layout not only aids in repairs but also enhances the overall usage experience.

Key Components Explained

Each segment illustrated in the schematic serves a unique purpose, contributing to the overall operation. Familiarizing oneself with these elements can prevent misuse and ensure longevity.

| Component | Description |

|---|---|

| Motor | Powers the entire mechanism, driving the blade for cutting tasks. |

| Blade | The sharp tool used to slice through materials, varying in type and size for different applications. |

| Fence | Provides a guide for accurate and straight cuts, adjustable to various widths. |

| Base | The sturdy platform that supports all components and ensures stability during operation. |

Benefits of Familiarity

Recognizing the elements in the schematic not only streamlines repair processes but also enhances safety. Knowledge of how each part interacts allows for informed decisions during usage, ultimately improving performance and user satisfaction.

Common Issues with Table Saw Parts

Understanding the typical challenges that can arise with essential components is crucial for maintaining optimal performance in woodworking equipment. Various factors can lead to malfunctions, impacting precision and safety during use. Identifying these common problems can help users troubleshoot effectively and ensure a longer lifespan for their machinery.

One frequent issue involves misalignment, which can result in inaccurate cuts and increased wear on the blade. Regularly checking the alignment of the components can prevent such discrepancies. Additionally, wear and tear on critical mechanisms can lead to reduced functionality. It’s important to inspect and replace any worn-out items promptly.

Another concern is the accumulation of debris, which can hinder movement and operation. Regular cleaning of the equipment can mitigate this problem. Furthermore, electrical failures may occur, often linked to damaged wiring or faulty switches. Ensuring all electrical components are in good condition is vital for safe operation.

Lastly, lubrication is essential for moving parts, as insufficient oiling can lead to grinding and friction. Regular maintenance practices, including lubrication, can significantly enhance the efficiency of the machinery and reduce the likelihood of mechanical failures.

Maintenance Tips for Longevity

Ensuring the durability and performance of your equipment requires regular upkeep and attention. By following specific guidelines, you can enhance its lifespan and efficiency, preventing unnecessary wear and tear.

Here are some essential maintenance practices:

| Task | Frequency | Tips |

|---|---|---|

| Clean surfaces | After each use | Remove dust and debris to prevent buildup. |

| Check alignment | Monthly | Ensure components are properly aligned for optimal performance. |

| Lubricate moving parts | Every few months | Use appropriate lubricants to reduce friction. |

| Inspect electrical components | Quarterly | Look for wear and replace damaged wires immediately. |

| Replace worn blades | As needed | Use high-quality replacements to maintain cutting efficiency. |

Upgrading Your Dewalt Table Saw

Enhancing your woodworking equipment can significantly improve performance and efficiency. By making thoughtful modifications, you can elevate the functionality and precision of your machinery, leading to better results in your projects.

Here are some upgrades to consider:

- Blade Replacement: Opt for high-quality blades tailored to specific materials.

- Fencing Systems: Install a more accurate and durable fence for better alignment.

- Motor Upgrades: Consider a more powerful motor for increased cutting capabilities.

- Extension Tables: Add an extension for larger workpieces and improved support.

Each of these enhancements can lead to the ultimate improvement in your equipment’s performance, allowing you to delve deeper into your woodworking projects with confidence.

Finding Replacement Parts Easily

Locating the necessary components for your tools can often feel like a daunting task. However, with the right approach and resources, you can simplify the process and ensure your equipment remains in optimal condition. Understanding where to search and how to identify what you need will save you both time and frustration.

Utilizing Online Resources

The internet is a treasure trove of information. Numerous websites provide detailed catalogs and descriptions, allowing you to find what you’re looking for with just a few clicks. Searching for your specific model along with the term “components” can lead you directly to reliable sources. Furthermore, forums and community groups can offer valuable insights and recommendations from fellow users.

Keeping Track of Model Numbers

One essential step is to keep your tool’s model number accessible. This information can significantly streamline your search. When you know the exact specifications, you can easily filter results and avoid confusion. Maintaining a record of your equipment, including its unique identifiers, will expedite any future replacements.

| Tip | Description |

|---|---|

| Check Manufacturer’s Website | Always visit the official site for the most accurate and updated information. |

| Join User Communities | Engage with other users for advice and tips on finding components. |

| Use Part Identification Tools | Leverage online tools to match your needs with available options. |

Comparing Models and Their Features

When exploring various woodworking machines, understanding the distinctions among different models is crucial. Each version offers unique characteristics that cater to diverse needs and preferences, making it essential to evaluate their specifications and functionalities.

For instance, one model might emphasize portability, featuring a lightweight design, while another could prioritize power, boasting a higher motor capacity. Additionally, some may include advanced safety features, enhancing user protection, whereas others focus on ease of use, streamlining setup and operation.

Examining cutting capabilities, precision adjustments, and accessory compatibility can also reveal significant differences. By delving into these aspects, users can make informed decisions tailored to their specific tasks and projects.

Essential Accessories for Table Saws

To enhance the efficiency and safety of woodworking tasks, having the right supplementary tools is crucial. These additions not only improve performance but also ensure precision in every cut.

- Push Stick: A vital tool for keeping hands at a safe distance from the blade.

- Blade Guard: An essential safety feature that protects users from accidental contact.

- Feather Board: Helps maintain consistent pressure against the material, promoting smoother cuts.

- Crosscut Sled: Ideal for making accurate crosscuts, providing stability during operation.

- Dust Collection System: Keeps the workspace clean and minimizes inhalation of harmful particles.

Incorporating these accessories can ultimately lead to better results and a more enjoyable woodworking experience.