In the realm of outdoor maintenance equipment, understanding the various components that contribute to optimal performance is essential for every operator. Whether you are a professional landscaper or a dedicated homeowner, familiarizing yourself with the intricate parts of your machine can enhance its functionality and longevity. Knowledge of these elements empowers users to make informed decisions regarding repairs and maintenance.

To effectively manage and troubleshoot your equipment, visual aids can play a crucial role. They provide clarity and help in identifying each component’s purpose and interconnections. By examining detailed illustrations, operators can gain insights into how different elements work together to achieve efficient cutting and trimming results.

As you delve into the specifics of your machinery, you’ll discover that a thorough understanding of its structure not only facilitates easier repairs but also enables better care practices. A well-maintained machine translates to improved performance and a more enjoyable lawn care experience, ultimately leading to healthier, more vibrant outdoor spaces.

Kubota ZD21 Mower Overview

This section provides a comprehensive look at a specific model designed for precision and efficiency in landscape maintenance. Engineered to tackle various terrain types, it combines power with user-friendly features, ensuring a smooth operation for professionals and homeowners alike.

Key Features

Equipped with a robust engine, this unit offers exceptional performance and durability. Its intuitive controls enhance maneuverability, making it suitable for intricate tasks. Additionally, advanced cutting technology ensures a clean finish, optimizing results with every use.

Benefits of Usage

Users benefit from reduced maintenance time and increased productivity. The compact design allows access to tighter spaces, while its ergonomic layout minimizes fatigue during extended use. Investing in this machine guarantees long-term efficiency and satisfaction.

Importance of Mower Deck Maintenance

Regular upkeep of cutting equipment is essential for ensuring optimal performance and longevity. Proper care not only enhances efficiency but also contributes to a better quality of work. Neglecting maintenance can lead to decreased effectiveness and potential damage, resulting in costly repairs.

Keeping all components in top condition helps prevent uneven cutting and reduces the risk of breakdowns. A well-maintained unit operates more smoothly and consumes less energy, saving both time and resources. Here are some key aspects of why maintenance is vital:

| Benefit | Description |

|---|---|

| Improved Performance | Regular checks and adjustments ensure that the machinery functions at its best, providing a clean and even cut. |

| Extended Lifespan | Consistent maintenance prevents wear and tear, significantly prolonging the lifespan of the equipment. |

| Cost Efficiency | Proactive care reduces the likelihood of major repairs, saving money in the long run. |

| Safety | Well-maintained machines are safer to operate, minimizing the risk of accidents caused by malfunctioning parts. |

In conclusion, dedicating time to the maintenance of cutting tools is not just a recommendation but a necessity for achieving peak performance and ensuring safety. Regular inspections, cleaning, and timely repairs are crucial practices that every operator should prioritize.

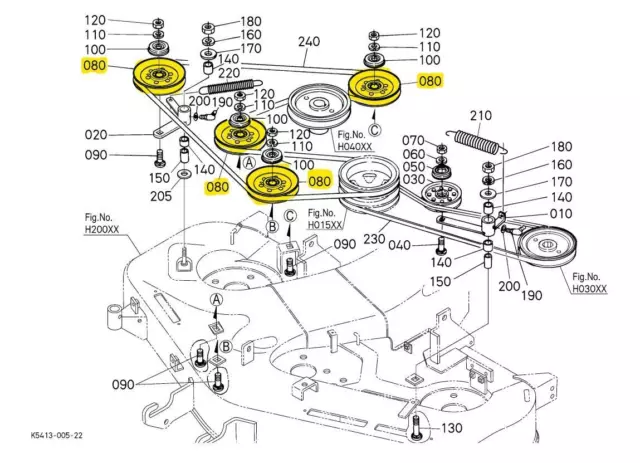

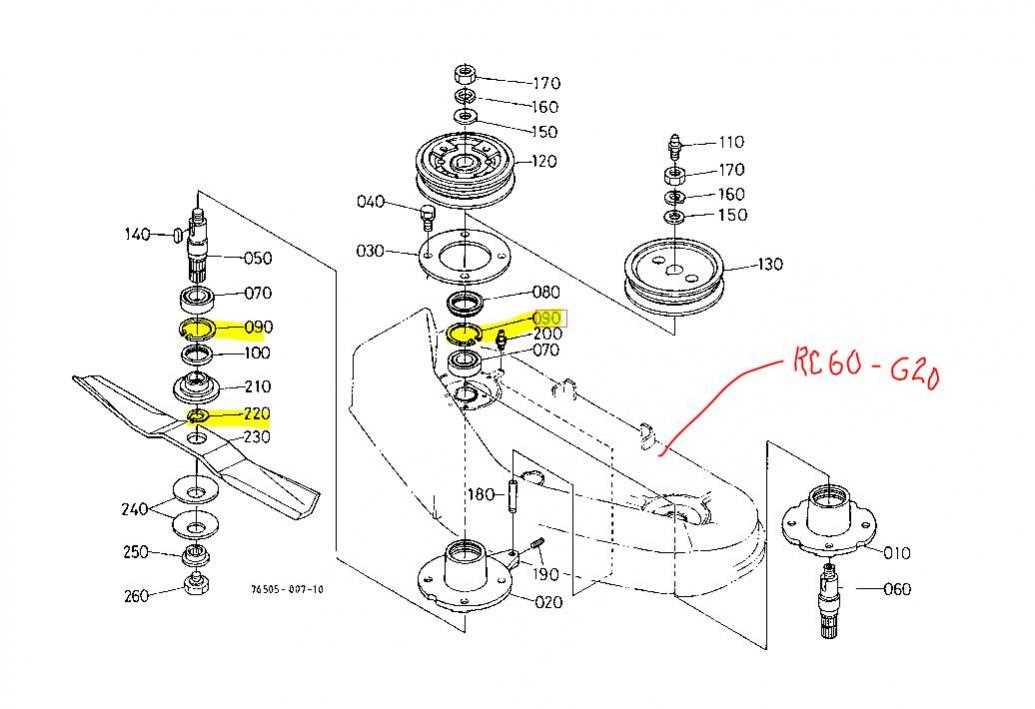

Key Components of the Mower Deck

The functionality and efficiency of a cutting mechanism largely depend on its essential elements. Understanding these components can greatly enhance maintenance and performance, ensuring a smooth operation during use.

- Cutting Blades: These are crucial for achieving a clean and even cut. Their design and sharpness play a significant role in the overall effectiveness.

- Spindle Assembly: This component houses the blades and allows them to rotate. It is vital for the stability and speed of the cutting elements.

- Deck Shell: The outer casing protects internal parts and supports the overall structure. Its design influences airflow and grass discharge.

- Lift Mechanism: This system enables the operator to adjust the height of the cutting blades, allowing for different grass lengths and types.

- Drive Belt: This component transfers power from the engine to the cutting assembly, ensuring that blades spin at the necessary speed.

Regular inspection and maintenance of these components can significantly extend the lifespan of the entire system, promoting optimal performance during operation.

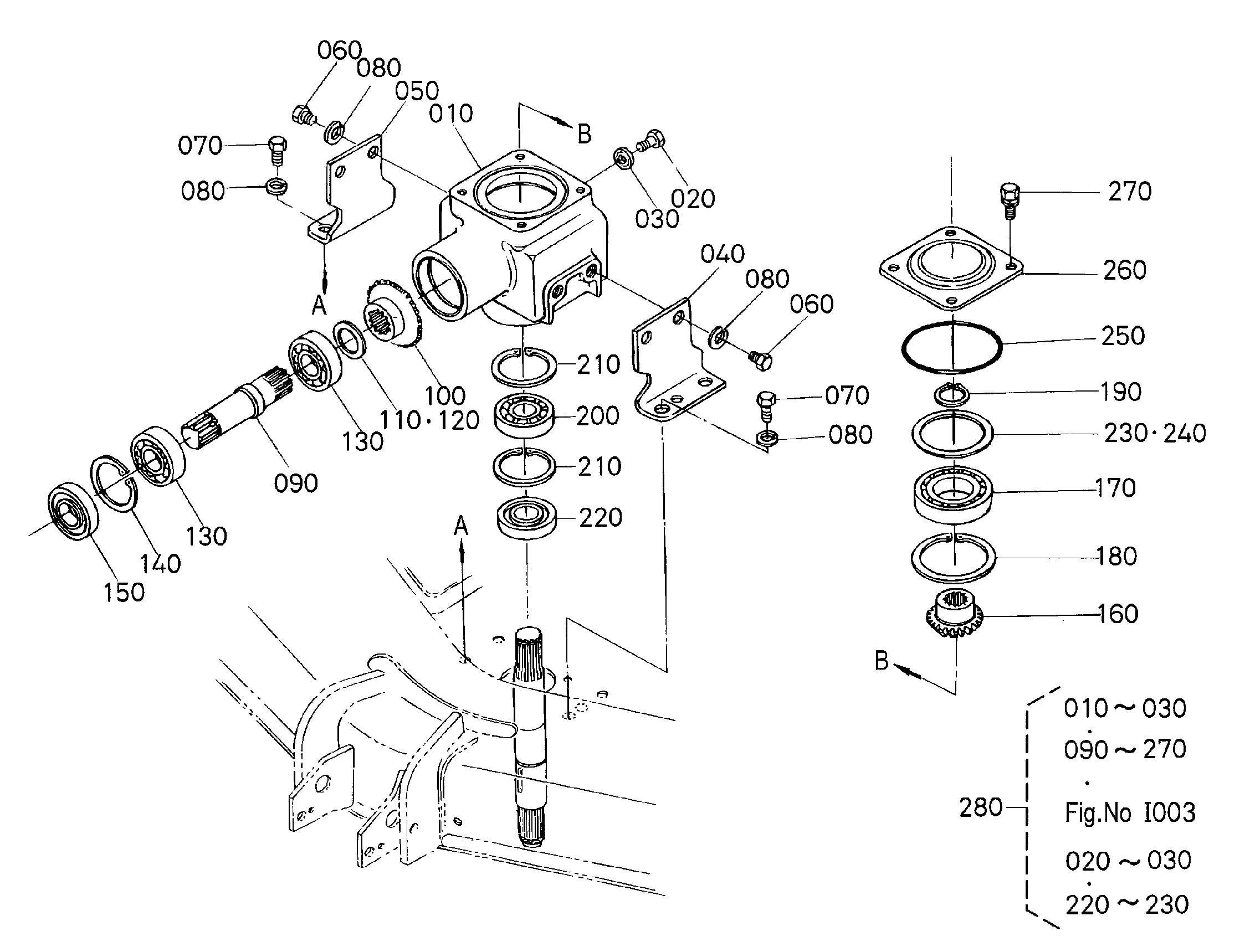

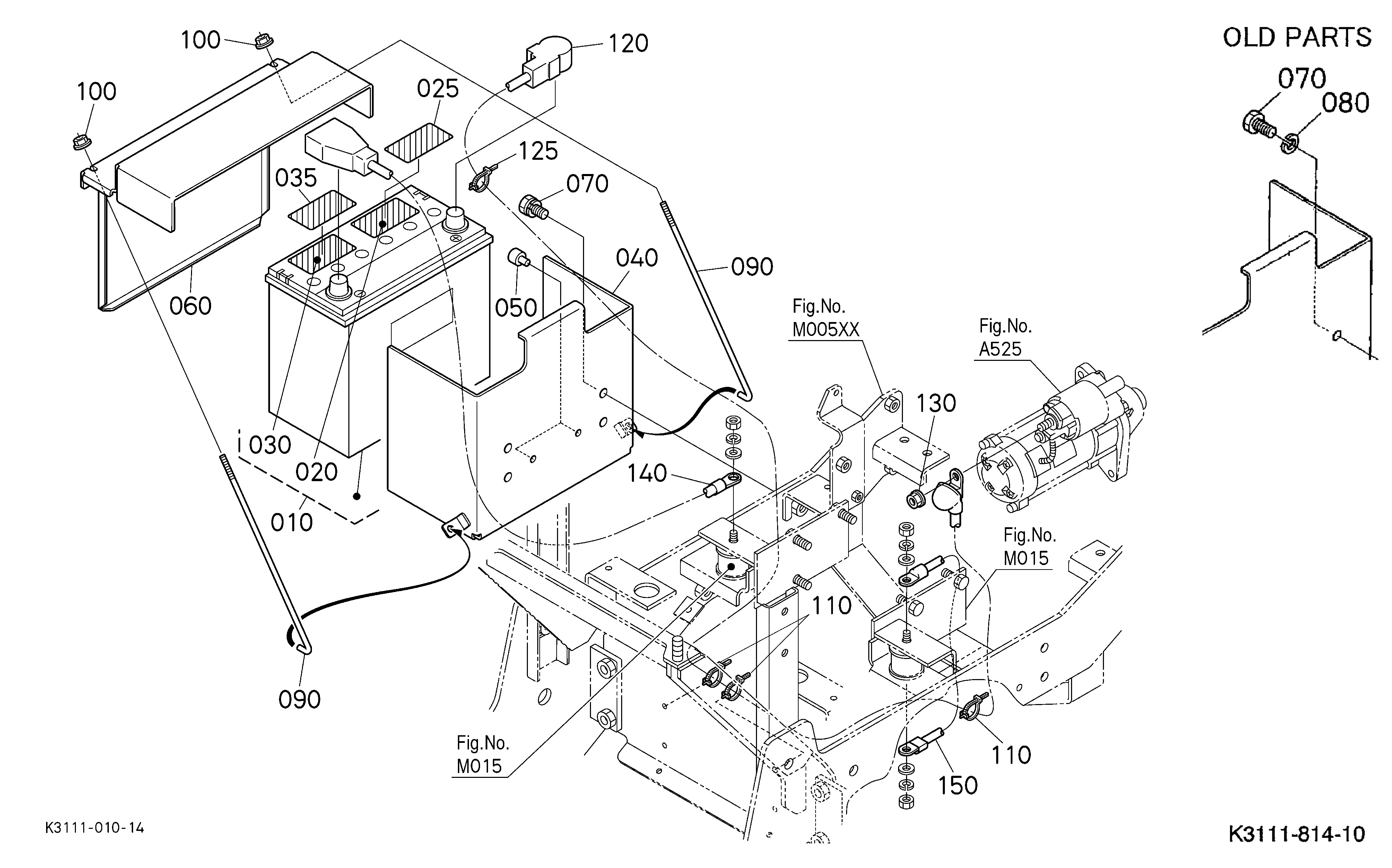

Understanding the Parts Diagram

The visual representation of components plays a crucial role in comprehending the assembly and functionality of machinery. It serves as a guide, helping users identify each element and its relationship to the overall system. A well-structured illustration provides clarity, ensuring that individuals can easily navigate through the various sections and understand how they interact.

By familiarizing oneself with the layout and nomenclature of the components, operators can enhance their maintenance skills and troubleshooting abilities. Recognizing the specific functions of individual pieces allows for more efficient repairs and replacements. Furthermore, this knowledge can significantly prolong the lifespan of the equipment, as regular upkeep becomes more straightforward.

Detailed schematics also aid in understanding the design intricacies and engineering behind the machinery. Users can appreciate the thoughtful arrangement of parts, which is essential for optimal performance. Ultimately, mastering the components’ representation empowers users to take better care of their equipment, ensuring reliability and efficiency in its operation.

Common Issues with Mower Decks

Maintenance equipment often encounters a variety of challenges that can impact performance and efficiency. Understanding these common problems is essential for effective upkeep and to ensure longevity. Below are some frequent issues and their potential solutions.

1. Uneven Cutting

One of the most prevalent concerns is uneven trimming, which can lead to an unsightly lawn. This issue may arise from:

- Incorrect blade height adjustment

- Worn or damaged blades

- Uneven tire pressure

Regular checks and adjustments can help maintain a consistent cut.

2. Clogging

Clogs can occur due to grass buildup, especially in wet conditions. This can hinder functionality and lead to:

- Reduced efficiency

- Increased wear on components

- Overheating

To prevent this, ensure timely cleaning and consider the frequency of use in different weather conditions.

Tips for Replacement and Repair

Maintaining and fixing your equipment can enhance its longevity and performance. This section offers practical advice for successful replacements and repairs, ensuring you get the most out of your machinery. Understanding the process can save both time and money while minimizing downtime.

Preparation Steps

Before you begin any repair or replacement, it’s essential to prepare adequately. Gather the necessary tools and materials, and review any relevant manuals or guides. This preparation will help streamline the process and prevent potential issues.

Replacement Process

When replacing components, follow these steps for a smooth operation:

| Step | Action |

|---|---|

| 1 | Disconnect the power source to ensure safety. |

| 2 | Carefully remove the old component, taking note of its placement. |

| 3 | Install the new component, ensuring it is securely fitted. |

| 4 | Reconnect the power source and test for functionality. |

By following these tips, you can effectively tackle replacements and repairs, leading to improved performance and reliability of your machinery.

Where to Find Replacement Parts

Finding suitable components for your equipment can enhance its performance and longevity. Whether you are maintaining or repairing, knowing the right sources is essential for a seamless experience.

Online Retailers

- Specialized websites offer a wide range of options.

- Marketplaces like Amazon and eBay can provide both new and used items.

- Manufacturer websites often have official listings.

Local Stores

- Visit nearby hardware or garden supply shops for immediate needs.

- Check with local dealerships that specialize in machinery.

- Ask for recommendations from fellow enthusiasts in your community.

Benefits of Using Genuine Parts

Utilizing authentic components for your equipment can significantly enhance performance and longevity. These original items are specifically designed to meet the precise specifications of the machinery, ensuring optimal operation and reducing the risk of malfunctions.

Enhanced Performance

When you choose original components, you are ensuring that every piece works seamlessly with the overall system. Here are some advantages:

- Improved efficiency during operation.

- Reduced wear and tear on surrounding parts.

- Consistent quality and reliability.

Cost-Effectiveness in the Long Run

While authentic items may have a higher upfront cost, their benefits often lead to savings over time. Consider the following:

- Lower maintenance costs due to fewer breakdowns.

- Extended lifespan of the machinery.

- Potential increase in resale value when the time comes.