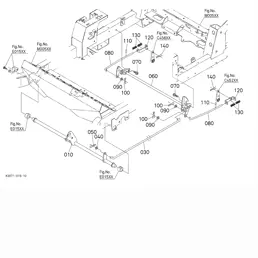

The cutting mechanism of any modern lawn equipment plays a crucial role in ensuring a smooth and efficient mowing experience. Whether for residential or commercial use, the intricate design and interconnected components of the system are essential for delivering optimal performance. It’s important to familiarize yourself with the layout and individual elements that work together to provide a precise cut on various types of terrain.

Each part of the cutting system contributes to the overall functionality, working in unison to maintain balance, reduce wear, and ensure longevity. By understanding the positioning and relationships between different components, you can effectively maintain and troubleshoot the equipment. This knowledge is particularly valuable when considering repairs or replacements to extend the life of your machinery.

In the following sections, we will explore the critical elements of the cutting mechanism, highlighting their roles and how they interact. By gaining a clearer perspective on this, you’ll be better prepared to address any issues and keep your equipment running smoothly.

Kubota Z421 Deck Overview

The cutting platform of this model is designed for precision and efficiency, allowing users to maintain large areas with ease. Engineered for durability and performance, the structure supports a range of cutting conditions, ensuring smooth and consistent results.

Main Features

- Reinforced structure for extended longevity

- Adjustable height settings to suit various terrains

- Optimized airflow for superior grass discharge

Performance and Design

Built with a focus on robustness, the cutting system integrates advanced features that promote even cutting and reduce maintenance requirements. The streamlined design ensures seamless operation, while the rugged construction allows for tackling tough mowing tasks effortlessly.

- Sturdy components that handle high workloads

- Easy-to-access maintenance points for quick adjustments

- Enhanced safety mechanisms to protect both the operator and the machine

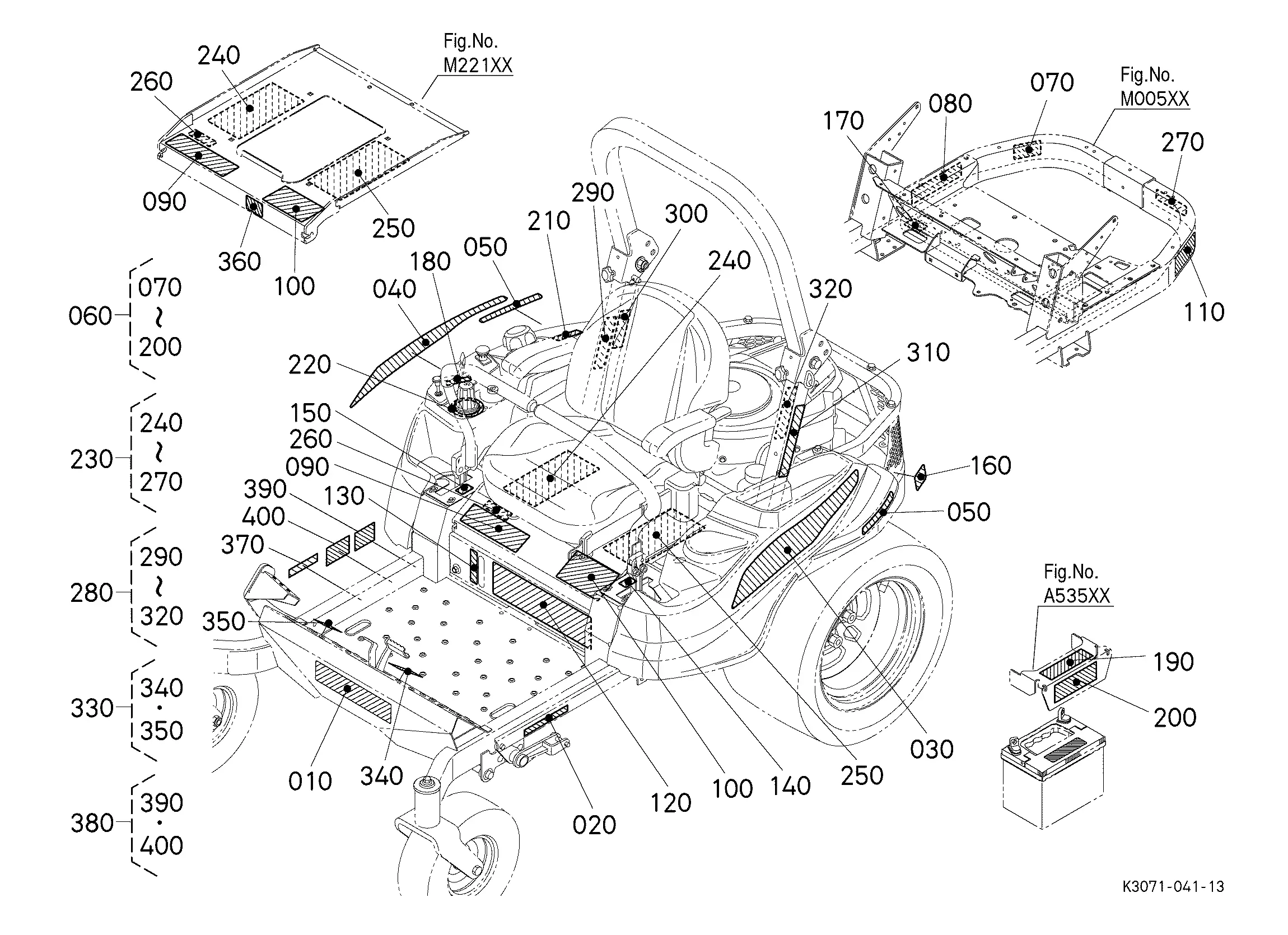

Main Components of Kubota Z421 Deck

The structure of this mower’s cutting system consists of several interconnected elements, each playing a key role in delivering optimal performance. These parts work together to ensure even grass cutting, durability, and efficient operation, making the machine highly effective for lawn maintenance.

Cutting Blades

The core of the system is the set of sharp blades designed to provide a clean and precise cut. These components rotate at high speeds and are crafted from robust materials to withstand wear and tear while maintaining their sharpness over time.

Spindle Assembly

Supporting the movement of the blades, the spindle assembly connects them to the machine’s power source. This essential element ensures the smooth and consistent rotation required for effective cutting. Proper maintenance of this part is crucial for avoiding vibrations and ensuring longevity.

How to Identify Parts in the Z421 Deck

Recognizing components within your machine’s cutting platform is essential for ensuring proper maintenance and replacement when necessary. A clear understanding of each element will help in keeping the equipment running efficiently and prolong its lifespan.

Main Structural Elements

- The frame forms the foundation, supporting all other pieces. It’s crucial to check its condition regularly to avoid any structural issues.

- The cutting blades are central to performance, ensuring a clean and even cut. Their sharpness and alignment need periodic evaluation.

- Spindles are responsible for the movement of the blades. Ensuring these are well-lubricated and free from damage is key to smooth operation.

Smaller, Vital Components

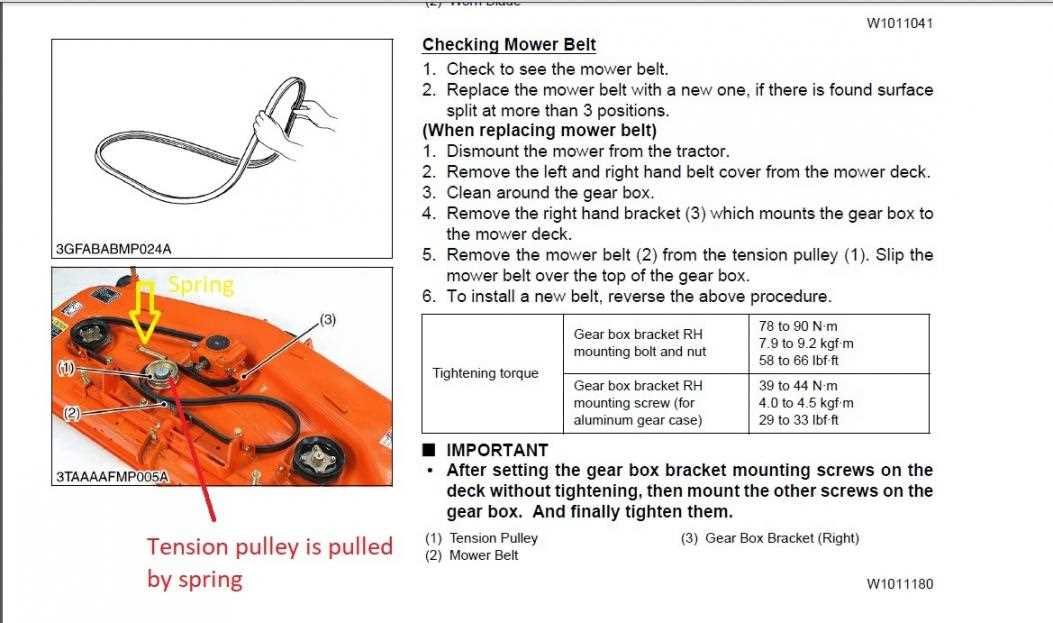

- Belt systems play a pivotal role in transferring power from the engine to the blades. Monitoring their tension and wear is important to avoid breakdowns.

- Pulleys aid in directing belt movement, ensuring everything runs efficiently. Inspect these for any signs of wear or misalignment.

Kubota Z421 Deck Maintenance Guide

Proper upkeep of the cutting platform is essential for maintaining the overall performance and longevity of your equipment. Regular attention to critical components ensures smooth operation and extends the life of the machinery. In this section, we will explore key practices for maintaining and optimizing the cutting mechanism to achieve efficient and consistent results over time.

Begin by inspecting the surface for any accumulated debris or signs of wear. Removing grass clippings, dirt, and other buildup helps prevent potential blockages that could affect performance. A clean surface also allows for more accurate cutting and reduces the risk of damage.

Next, focus on blade care. Sharp and balanced blades are vital for producing a clean, even cut. Regularly checking and sharpening them ensures they remain effective, reducing strain on the motor and improving fuel efficiency. Additionally, examine the alignment to prevent uneven wear and potential issues during operation.

Lubrication of moving components is another crucial aspect of routine care. Apply appropriate grease or oil to bearings and other joints to ensure they function smoothly and reduce friction. This helps avoid premature wear and keeps the mechanism running efficiently.

Lastly, perform routine inspections of the belts and pulleys to ensure they are in good condition. Replace worn or damaged belts promptly to prevent interruptions during ope

Common Issues with Z421 Deck Parts

When it comes to maintaining the efficiency and longevity of your equipment, it’s important to be aware of common problems that may arise over time. Regular use and exposure to outdoor elements can lead to a variety of issues that require timely attention. Understanding these potential challenges can help ensure smoother operation and reduce downtime.

- Belt Slippage: One of the most frequent concerns is the slipping of the drive belt. This can occur due to wear, improper tension, or debris buildup, leading to reduced performance.

- Uneven Cutting: A common problem many users experience is an uneven cut. This could be caused by dull blades, uneven tire pressure, or misaligned components.

- Blade Vibration: Vibration during operation often points to issues with the cutting blades. This can be due to imbalance, damage, or improper installation.

- Rust and Corrosion: Exposure to moisture and harsh conditions can result in rust forming on key metal components, which can weaken their structure and affect overall performance.

- Spindle Failures:

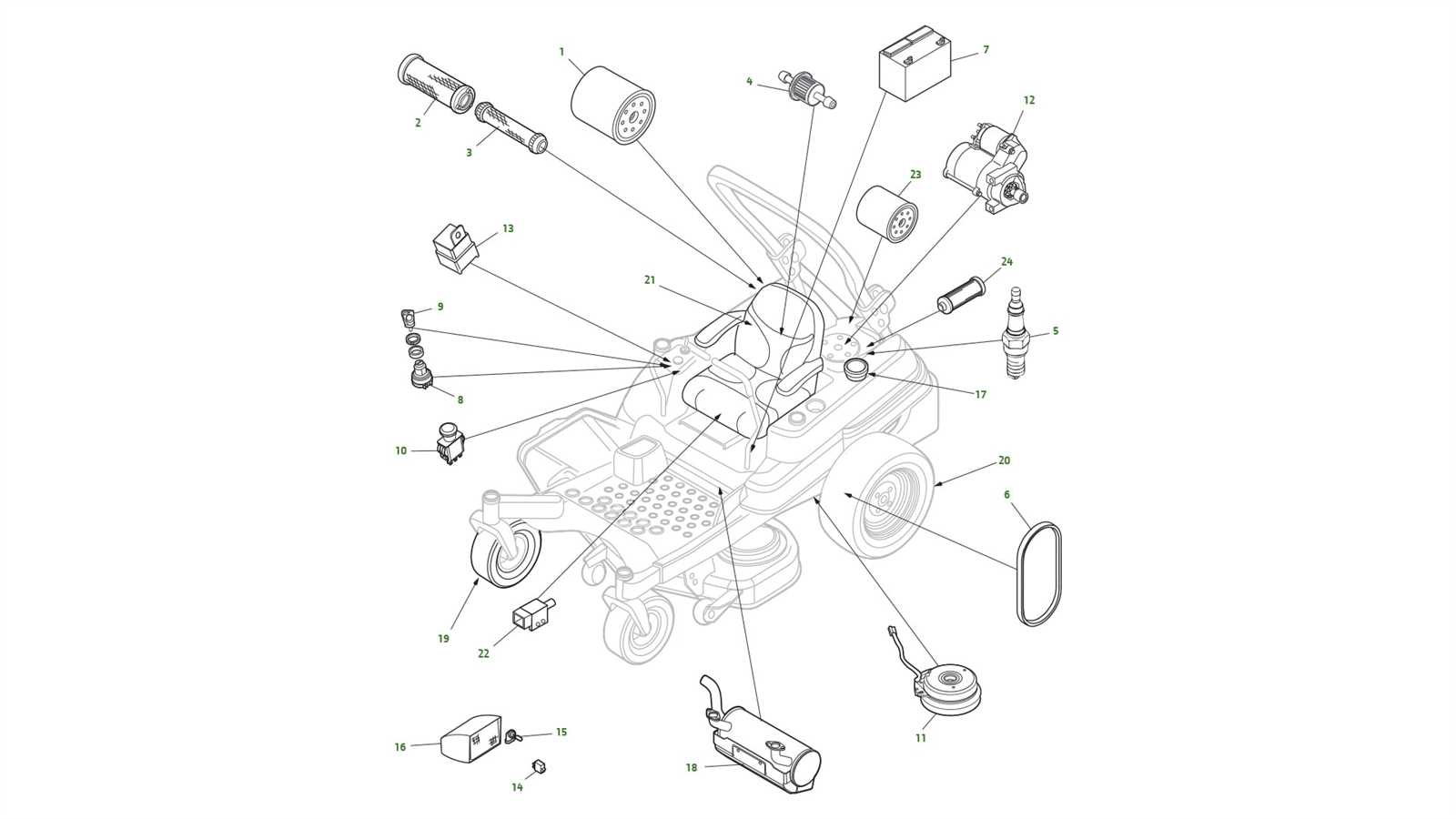

Replacing Worn-Out Mower Cutting System Components

Over time, frequent use of a cutting system leads to wear and tear on essential elements. Regular inspection and timely replacement of worn-out components are crucial to maintaining efficiency and prolonging the equipment’s lifespan. Understanding which elements are prone to damage can help prevent unexpected issues and ensure smooth operation.

When it’s time to replace the aging components, it is important to use compatible parts for seamless functionality. Below is a guide to common items that might need replacement and tips on identifying when they are due for servicing:

Component Signs of Wear Replacement Tips Blades Dull edges, uneven cuts Sharpen or replace if excessively worn Belt Cracks, fraying Inspect regularly and replace when signs of deterioration appear Spindles Unusual vibrations, noisy operation Replace if damaged or causing instability Upgrading for Better Performance

Enhancing the efficiency and durability of your mowing equipment is crucial for achieving optimal results in any landscaping project. By focusing on key improvements, you can ensure a more effective cut, smoother operation, and longer-lasting functionality. There are several areas where thoughtful upgrades can make a significant difference in performance, from improving blade quality to adjusting the overall setup for better ergonomics.

Below is a comparison table showcasing potential upgrade areas and their benefits:

Upgrade Area Benefit Blade Sharpness and Type Improved cutting precision and reduced wear Height Adjustment System More flexibility for varying grass lengths Anti-Scalp Features Prevents damage to uneven terrain Vibration Control Enhances operator comfort and control Build Material Where to Find Kubota Z421 Deck Parts

When it’s time to maintain or repair your equipment, knowing where to locate the necessary components can be essential for ensuring its longevity. Whether you’re replacing worn-out elements or upgrading certain features, finding reliable sources for these items is crucial. Several options are available that can meet your needs, offering both convenience and quality.

Authorized dealerships are often the first place to start your search. These locations provide certified products that are designed specifically for your machinery, ensuring compatibility and performance. Additionally, they may offer expert advice and assistance in choosing the correct components for your maintenance needs.

Another option is to explore online retailers specializing in agricultural or landscaping machinery. These platforms typically offer a wide range of options, often at competitive prices. Many online stores provide detailed descriptions and customer reviews, helping you make informed decisions. Moreover, they frequently offer shipping options that can deliver the required items directly to your door.

If you’re looking for a cost-effective solution, consider searching for second-hand or refurbished elements through classified ads or local sel