Effective lawn maintenance requires a comprehensive understanding of the various components that contribute to the functionality of cutting machinery. Each section of these devices plays a crucial role in ensuring efficient operation, from the cutting mechanisms to the support structures. This knowledge not only aids in effective usage but also simplifies maintenance and repair tasks.

Within the realm of gardening machinery, familiarity with the configuration of different assemblies is essential for troubleshooting and optimizing performance. By examining the specific arrangements and relationships between parts, operators can identify potential issues and implement solutions swiftly. This insight empowers users to keep their equipment in peak condition, ensuring lush and healthy lawns.

Visual aids such as schematics serve as invaluable resources for both seasoned professionals and novices. They offer a clear representation of how components interact and function together, enabling better comprehension of overall mechanics. Understanding these intricacies ultimately enhances the user’s ability to manage their tools effectively, resulting in superior landscaping results.

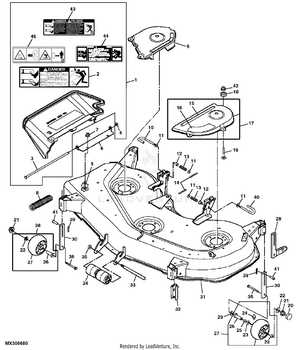

Understanding the LX279 Mower Deck

The cutting mechanism of lawn care machines is essential for achieving smooth, even results when maintaining a well-manicured lawn. This system, which consists of various interconnected components, works in unison to ensure that grass is properly trimmed and collected. Gaining a clear understanding of how each part functions within this mechanism can help in both maintenance and troubleshooting, allowing users to optimize the performance of their equipment.

Key Components of the Cutting System

The main elements involved in the cutting process include rotating blades, support brackets, and the housing that contains them. Each of these components plays a critical role in ensuring that the blades rotate smoothly and efficiently. Regular inspection of these parts for wear and damage can significantly improve the overall performance of the system, allowing for cleaner cuts and reducing the likelihood of malfunctions during operation.

Maintaining Optimal Performance

To keep the system operating at peak efficiency, it’s important to regularly inspect and replace worn components. Lubricating moving parts and checking for any obstructions can prevent unnecessary strain on the machine. Additionally, keeping the blades sharp and free from debris ensures that the cutting action remains effective, reducing the effort required to maintain your lawn while also prolonging the lifespan of the equipment.

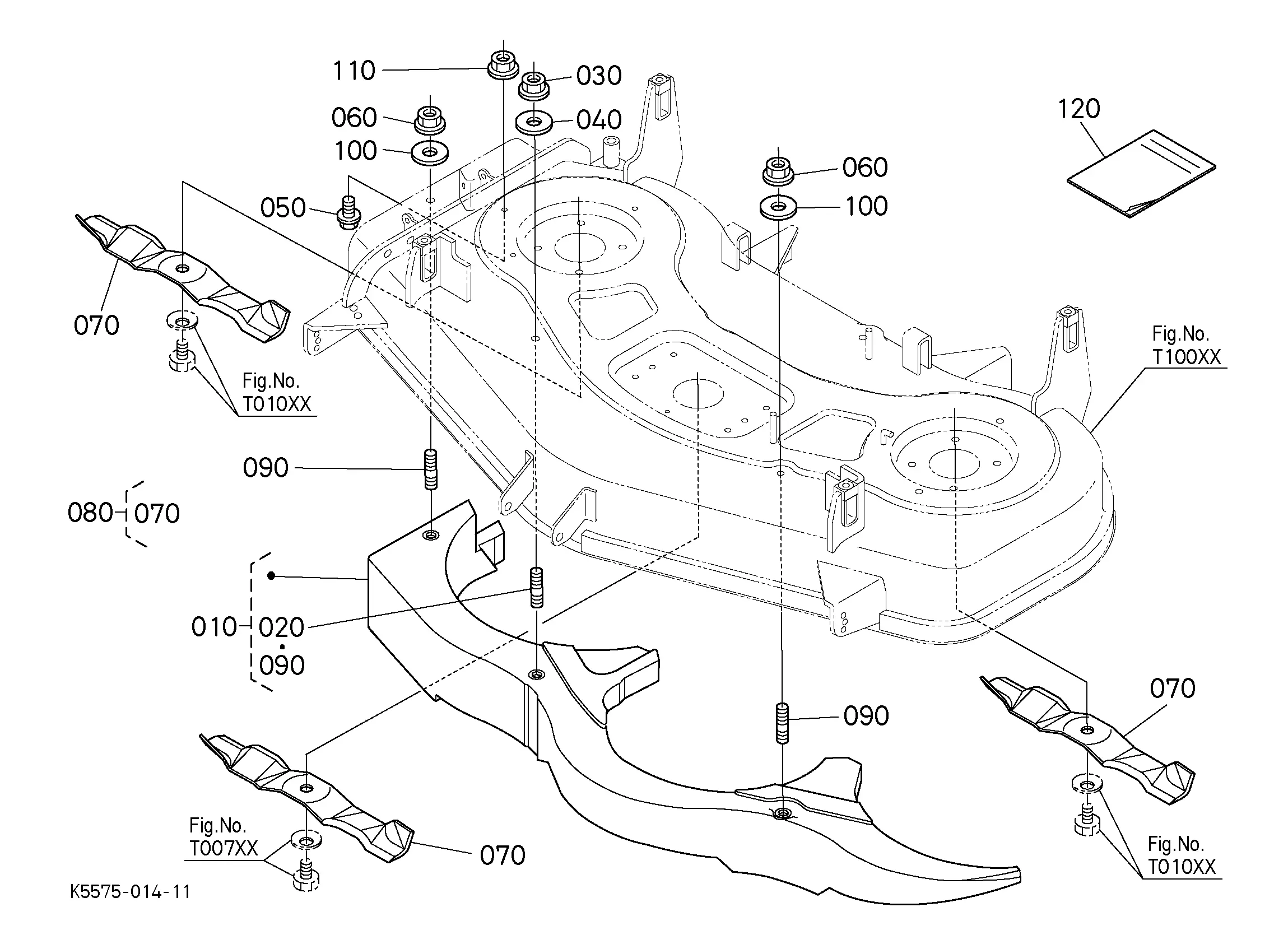

Components of the 48C Mower Deck

The assembly in question consists of several key elements that work in unison to ensure smooth operation and effective grass cutting. Each individual component plays a crucial role in providing a precise, clean finish. The combination of structural parts, rotating blades, and supporting elements makes the entire system highly efficient and durable under various conditions. Understanding the functions of each part allows for proper maintenance and troubleshooting when needed.

Below is an overview of the main elements that make up this cutting apparatus:

| Component | Description |

|---|---|

| Housing | The protective casing that holds all internal components together and ensures their alignment during operation. |

| Blades | Sharp, rotating elements designed to cut through grass, providing a clean and even trim across the surface. |

| Spindles | Mechanical devices that house and support the rotating blades, allowing them to spin efficiently while minimizing friction. |

| V-Belts | Rubber belts that transmit power from the engine to the spindles, ensuring the rotation of the blades. |

| Pulley System | A set of pulleys that assist in distributing power from the engine to the various rotating elements of the system. |

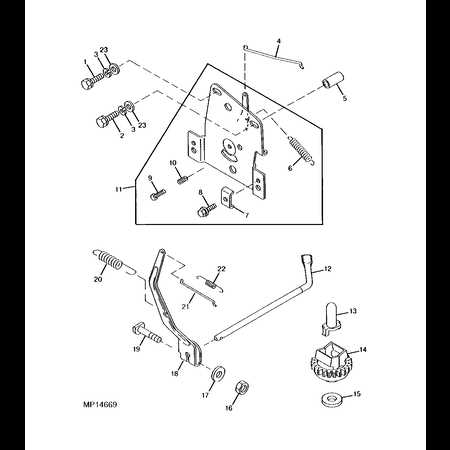

| Lift Mechanism | A system that allows the operator to adjust the height of the cutting blades for varying grass lengths and terrain conditions. |

| Anti-Scalp Wheels | Small wheels positioned around the housing to prevent the blades from scalping the grass, maintaining an even cut across uneven ground. |

Each part works synergistically to provide an optimal cutting experience, enhancing both performance and longevity when properly maintained. Regular inspection and replacement of worn parts are key to sustaining top-tier operation over time.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your equipment operates at peak efficiency. By following a few simple guidelines, you can extend the lifespan of your machinery and enhance its overall functionality. Proper care not only prevents costly repairs but also guarantees smooth operation during use.

1. Clean the Equipment

After each use, it’s crucial to remove any debris, grass clippings, and dirt. This helps prevent buildup that can lead to rust and other issues. Use a brush or a blower to keep all surfaces clear and ensure proper airflow.

2. Inspect and Replace Blades

Keep blades sharp for optimal cutting performance. Dull blades can tear grass rather than cut it cleanly, which may lead to disease. Check for wear and replace them as needed to maintain a healthy lawn.

3. Check Fluid Levels

Regularly monitor oil and fuel levels to prevent engine strain. Change the oil according to the manufacturer’s recommendations to ensure smooth operation and longevity of the engine.

4. Tighten Loose Parts

Periodically inspect all fasteners and components for looseness. Vibration during operation can cause parts to become loose over time. Ensuring everything is tightly secured can prevent damage and improve performance.

5. Store Properly

When not in use, store your equipment in a dry, sheltered location. This protects it from the elements and minimizes wear. Additionally, consider using a cover to shield it from dust and moisture.

By incorporating these maintenance practices into your routine, you can ensure that your machinery remains reliable and efficient for years to come.

Common Issues with Mower Decks

Maintaining the cutting system of lawn care equipment is essential for achieving an even, efficient cut. Various challenges can arise that affect performance, often resulting in uneven trimming, poor grass collection, or mechanical failure. Understanding these common issues is crucial for proper upkeep and troubleshooting.

- Clogging and Buildup: Grass and debris can accumulate, hindering the system’s ability to cut effectively. Regular cleaning is needed to avoid blockages.

- Uneven Cuts: If the machine is not leveled properly or blades are damaged, the result is an inconsistent lawn appearance. This often requires adjusting the equipment’s height or replacing worn parts.

- Worn Blades: Dull or damaged cutting edges make the cutting process inefficient. Regular inspection and timely blade sharpening or replacement are necessary for optimal performance.

- Vibration: Excessive shaking during operation often indicates loose components or misalignment, which can cause further damage if not addressed promptly.

- Drive Belt Issues: A worn or broken belt can disrupt the power transfer to the blades. Regular monitoring of belt tension and condition helps prevent failures.

- Rust and Corrosion: Exposure to moisture can lead to rust, especially on metal parts. Proper storage and occasional lubrication can mitigate this risk.

Identifying these common issues early and performing regular maintenance ensures that the equipment continues to operate smoothly and effectively, reducing the likelihood of major repairs or replacements.

Finding Replacement Parts Easily

Locating suitable components for your equipment can streamline maintenance and enhance performance. By knowing where to search and which resources to utilize, you can ensure your machinery remains in optimal condition.

- Online retailers: Numerous websites specialize in equipment components, offering detailed catalogs and diagrams.

- Local dealers: Authorized sellers often have the latest parts and expert advice on compatibility.

- Forums and communities: Engaging with fellow enthusiasts can provide insights on sourcing rare items.

- Manufacturer websites: Official sites frequently feature parts lists and ordering options directly.

Utilizing these resources can significantly reduce downtime and enhance the efficiency of your machinery.

How to Read the Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repairs. These visuals provide a comprehensive overview of components, helping users identify each element’s placement and function. By familiarizing yourself with the layout and symbols used, you can streamline the repair process and ensure you have the necessary items for any job.

Start by examining the key, which often explains the various symbols and numbers associated with each component. This guide helps clarify how different parts interact within the larger system. Focus on the labeled sections to pinpoint specific items, noting their arrangement and connections to enhance your understanding.

It’s also beneficial to reference the list accompanying the illustration, as it provides detailed descriptions and part numbers for easy ordering. Cross-referencing the visual with this list can prevent confusion and ensure you obtain the correct replacements. Mastering these techniques will ultimately simplify your repair tasks.

Tools Needed for Mower Repair

To effectively maintain and fix your grass-cutting equipment, having the right tools is essential. This ensures that repairs are done efficiently and safely, leading to optimal performance.

- Wrenches: Adjustable and socket wrenches for loosening and tightening bolts.

- Screwdrivers: Both flat-head and Phillips for various screws.

- Pliers: Needle-nose and slip-joint for gripping and manipulating components.

- Torque Wrench: For applying precise torque to fasteners.

- Blades: Sharp replacement blades for optimal cutting.

In addition to these, a few specialized tools may be required based on specific issues.

- Oil Filter Wrench: To easily change the oil filter.

- Battery Tester: For checking battery health.

- Spark Plug Socket: Necessary for replacing spark plugs.

Investing in quality tools can make all the difference in maintenance tasks, ultimately extending the life of your equipment.

Upgrading Your Mower Deck

Improving the cutting performance of your lawn equipment can make a significant difference in the quality of your lawn care. Whether you want a more even cut, better grass collection, or increased durability, upgrading essential components can provide long-term benefits. In this section, we’ll explore key areas for enhancing your machine’s functionality and efficiency.

Key Components to Consider

When thinking about enhancements, several critical elements can contribute to improved performance. These include the blade system, frame, and attachment mechanisms. Upgrades in these areas can lead to smoother operation, reduced maintenance costs, and overall enhanced efficiency. Carefully selecting quality replacements or enhancements ensures that your equipment will meet your needs for years to come.

Popular Upgrade Options

Here are a few upgrades that can help elevate your machine’s capabilities:

| Upgrade | Benefits |

|---|---|

| High-Performance Blades | Sharper, longer-lasting blades for a cleaner cut and better efficiency. |

| Reinforced Frame | Increased durability and strength for handling tougher terrains. |

| Mulching Kit | Improved grass recycling and reduced waste with a more eco-friendly approach. |

| Quick Attach System | Faster and easier attachment/detachment of equipment for time-saving and convenience. |

By choosing the right parts, you can ensure your machine works at peak performance, providing a more efficient and enjoyable experience every time you use it. Consider what upgrades best suit your needs and preferences to get the most out of your investment.

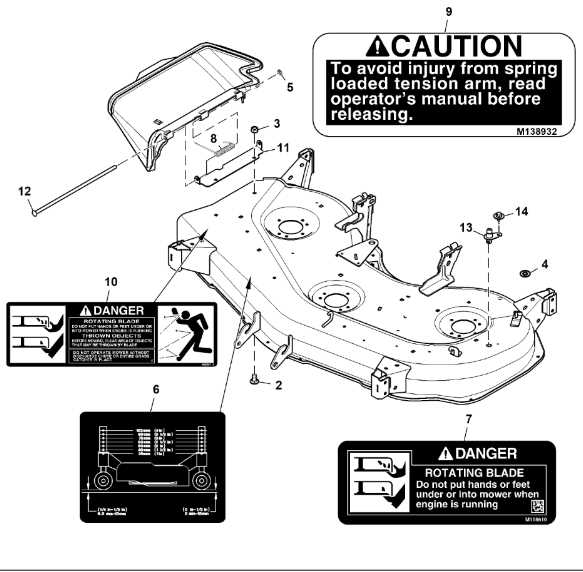

Safety Precautions During Repairs

When performing maintenance or repairs on outdoor machinery, ensuring personal safety should be the top priority. Proper precautions not only protect the individual but also ensure the longevity and efficiency of the equipment. Working with mechanical components can pose risks if the correct safety measures are not followed, so it is essential to understand and adhere to recommended guidelines throughout the process.

Preparation Before Starting

Before beginning any repair work, make sure the equipment is turned off and completely powered down. Disconnect the battery or any power sources to avoid accidental starts. Wear appropriate protective gear, such as gloves, goggles, and steel-toed boots, to guard against sharp edges and flying debris. A well-organized workspace is essential for both efficiency and safety, so ensure that tools and replacement parts are within easy reach.

Handling Tools and Components

Use only the recommended tools for the task at hand. Ensure that all tools are in good condition, with no loose or broken parts. When handling components, especially heavy or sharp objects, exercise caution. Store small parts in labeled containers to prevent loss or misplacement during the repair process. Always follow the manufacturer’s instructions and guidelines to avoid any accidents or damage to the machinery.

By taking these precautions seriously, you can minimize the risks associated with equipment repairs and ensure a smooth, safe process for both yourself and the machinery.