When maintaining a lawn care machine, it’s essential to comprehend its various components and how they interact. A detailed exploration of these elements can significantly enhance the performance and longevity of your equipment. Whether you’re a hobbyist or a professional, knowing the inner workings will help you troubleshoot and make informed decisions.

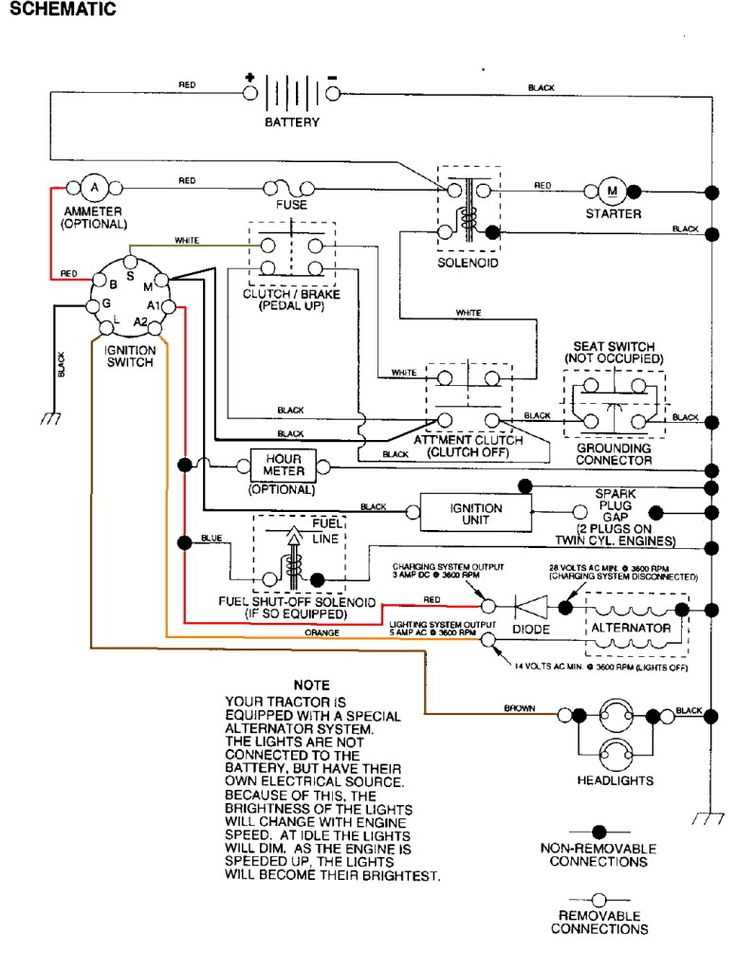

Illustrating the Relationships between different sections can aid in recognizing potential issues and guide you through the repair process. By visualizing how each part fits into the overall system, you’ll gain clarity on maintenance tasks and upgrades.

Furthermore, understanding the layout of these essential pieces can streamline your workflow. With the right information at hand, you can effectively manage repairs, ensuring that your lawn care tasks are executed flawlessly.

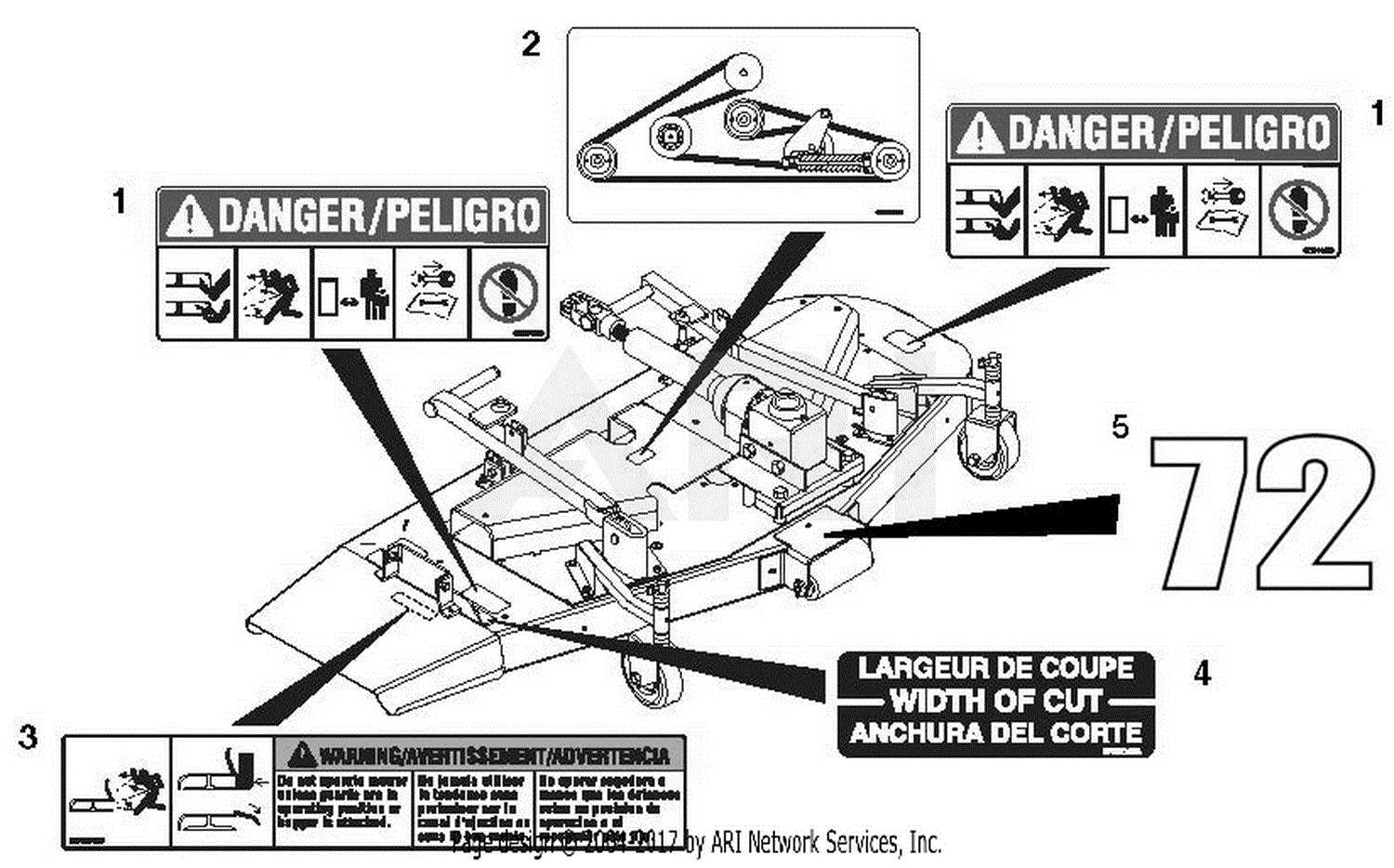

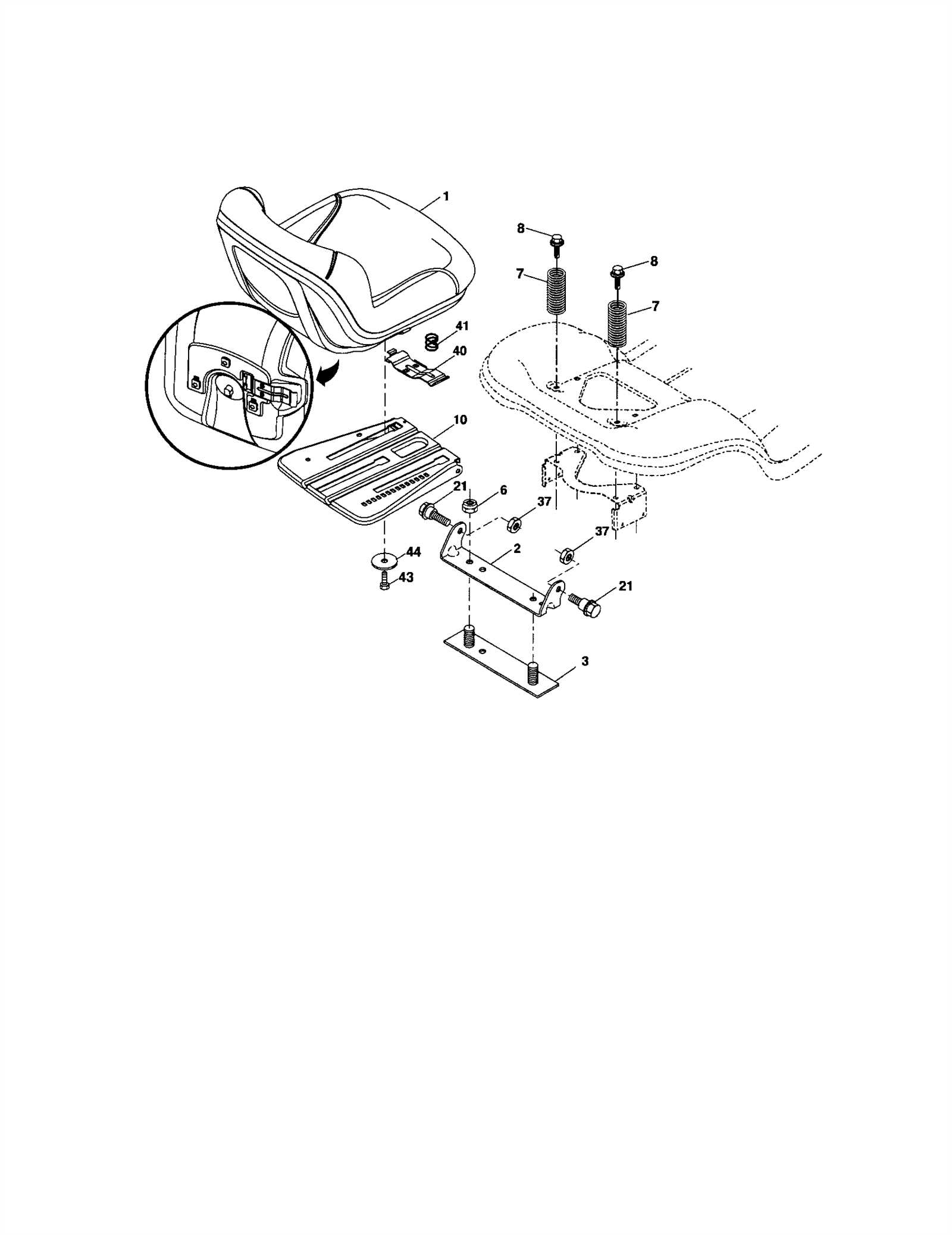

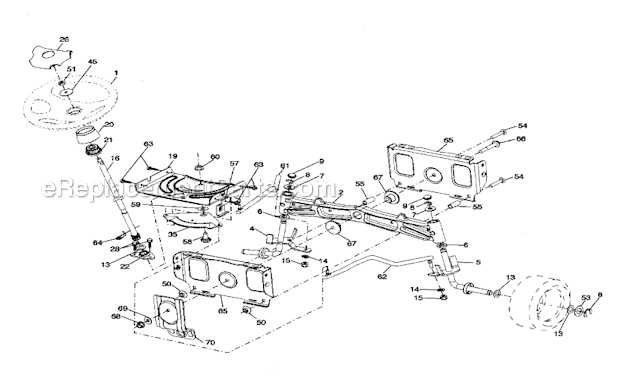

Understanding Craftsman YS4500 Deck Components

This section aims to explore the essential elements that contribute to the functionality and performance of your lawn care equipment. Recognizing these components allows for better maintenance and enhanced efficiency.

Key elements to consider include:

- Cutting mechanism: A crucial part that determines the quality of the cut.

- Support structure: Provides stability and durability during operation.

- Adjustment features: Allow for customized cutting heights and angles.

- Drive system: Ensures smooth movement and effective power transfer.

Understanding each element’s role is vital for optimal performance and longevity.

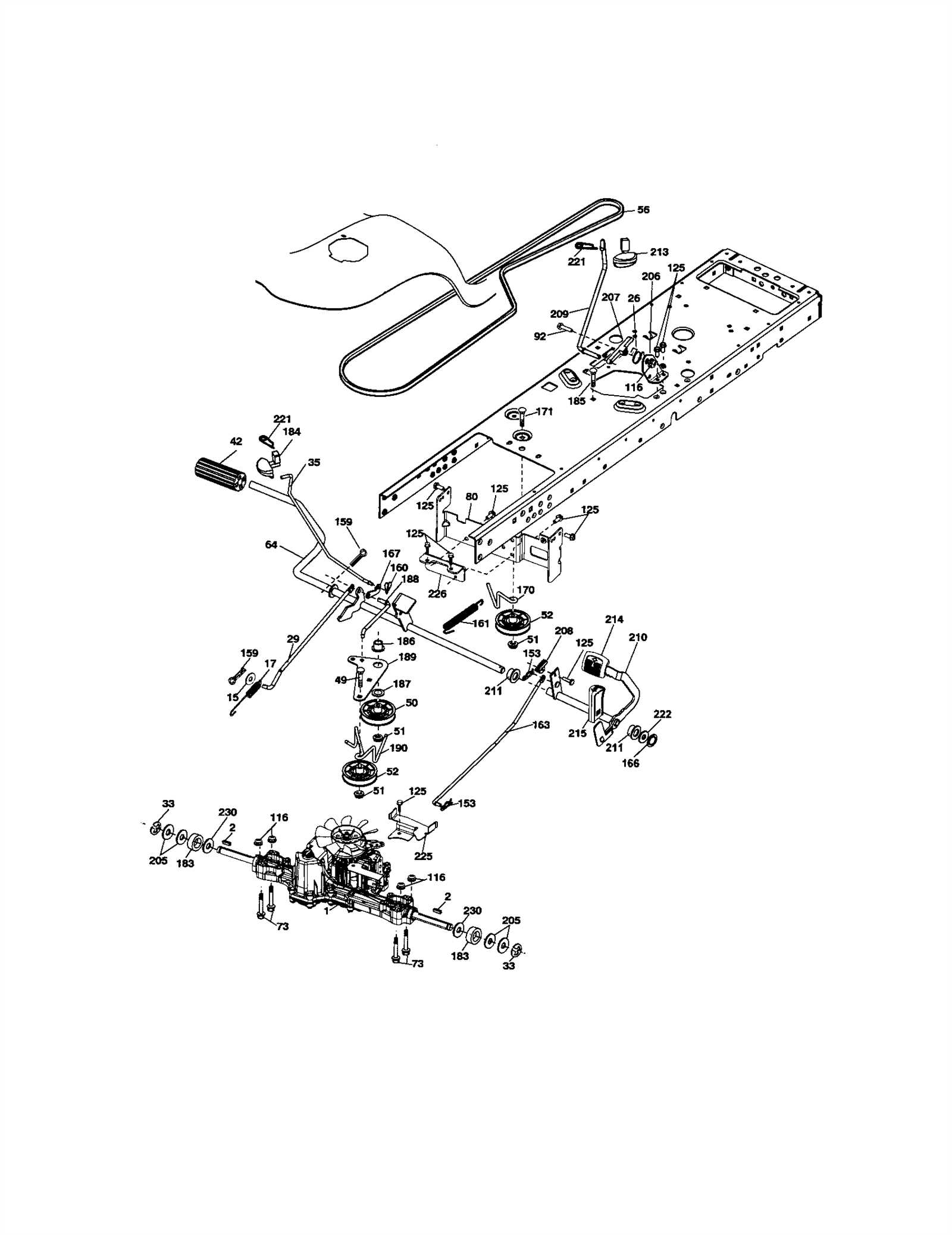

Key Features of the YS4500 Deck

The design and functionality of this particular cutting platform are crucial for achieving optimal performance and efficiency in lawn care. It combines durability and innovation to meet the needs of both residential and professional users. Understanding its main characteristics can help in making informed decisions regarding maintenance and usage.

| Feature | Description |

|---|---|

| Robust Construction | Engineered with high-quality materials to withstand rigorous use, ensuring longevity and reliability. |

| Adjustable Height | Allows for customizable cutting lengths, providing versatility for different types of grass and terrain. |

| Efficient Design | Optimized shape enhances airflow, resulting in a superior grass cutting and mulching performance. |

| Easy Maintenance | Features accessible components for straightforward upkeep, minimizing downtime and repair costs. |

| Compatibility | Designed to work seamlessly with various models, ensuring a broad application range and convenience for users. |

Common Issues with Deck Parts

Maintaining a lawn care machine requires attention to various components, each of which can encounter specific problems over time. Understanding these common difficulties can help owners identify and resolve issues efficiently, ensuring optimal performance and longevity of their equipment.

Frequent Problems

- Wear and Tear: Continuous use can lead to degradation, especially in high-contact areas.

- Alignment Issues: Misalignment can cause uneven cutting, affecting the quality of the lawn.

- Corrosion: Exposure to moisture may result in rusting, compromising the integrity of metallic components.

- Loose Fasteners: Vibration during operation can loosen bolts and screws, necessitating regular checks.

Symptoms to Watch For

- Uneven grass height post-mowing.

- Strange noises during operation.

- Visible damage or bending of components.

- Difficulty in maneuvering or controlling the machine.

Being aware of these issues can aid in timely maintenance and repairs, enhancing the overall efficiency of your lawn care machinery.

Benefits of Regular Maintenance

Consistent upkeep of your equipment offers numerous advantages that enhance performance and longevity. By dedicating time to regular checks and repairs, you can ensure efficient operation and prevent potential issues before they escalate.

- Improved Performance: Routine servicing helps maintain optimal functionality, ensuring that your equipment operates at its best.

- Extended Lifespan: Regular attention can significantly increase the durability of your machinery, allowing you to enjoy its benefits for a longer period.

- Cost Savings: Investing in maintenance can prevent costly repairs and replacements, ultimately saving you money in the long run.

- Safety Assurance: Keeping equipment in top condition reduces the risk of accidents, providing a safer working environment.

- Enhanced Efficiency: Well-maintained machinery often uses less energy, leading to lower operational costs and a smaller environmental footprint.

In conclusion, regular maintenance not only enhances performance but also safeguards your investment, making it a vital practice for any equipment owner.

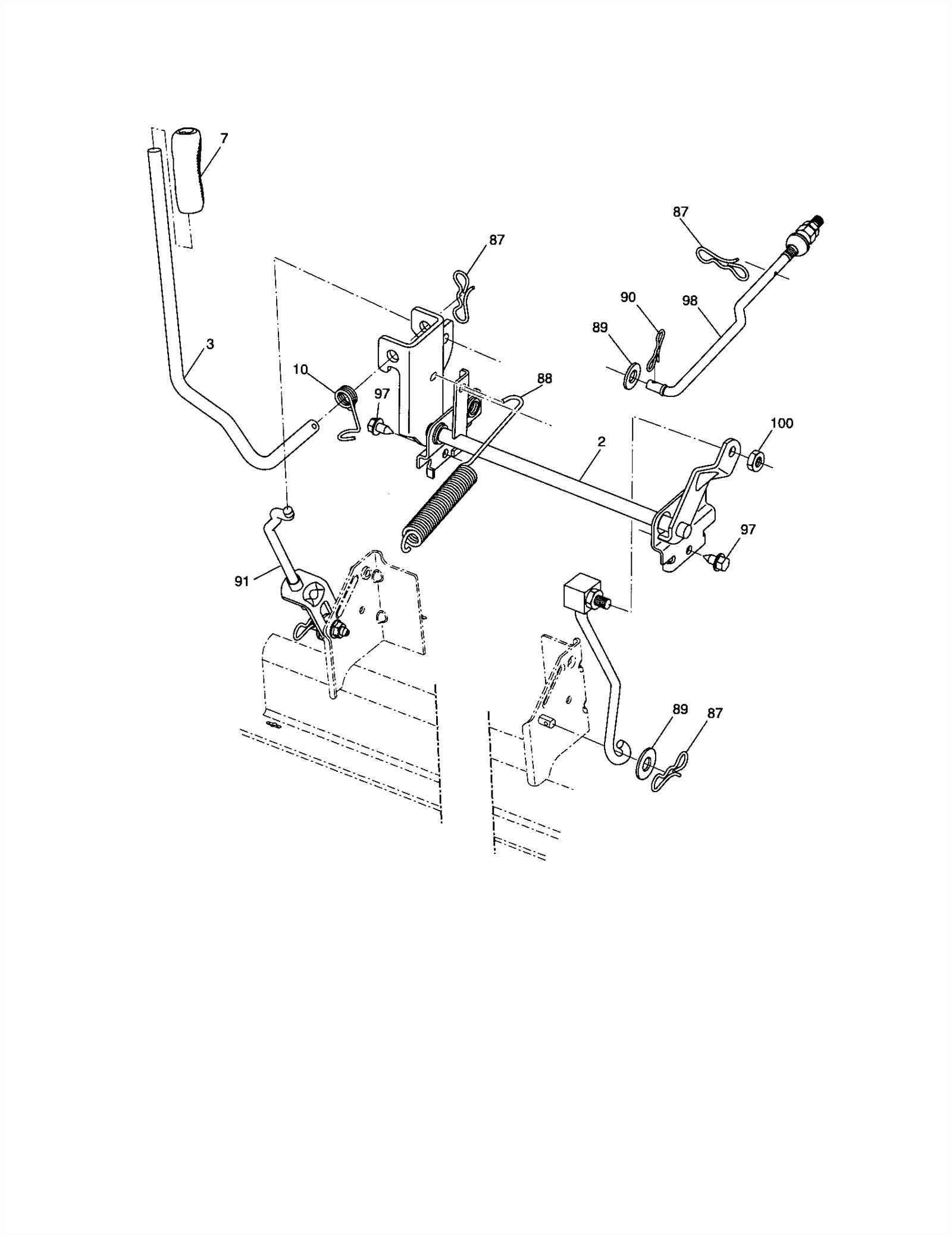

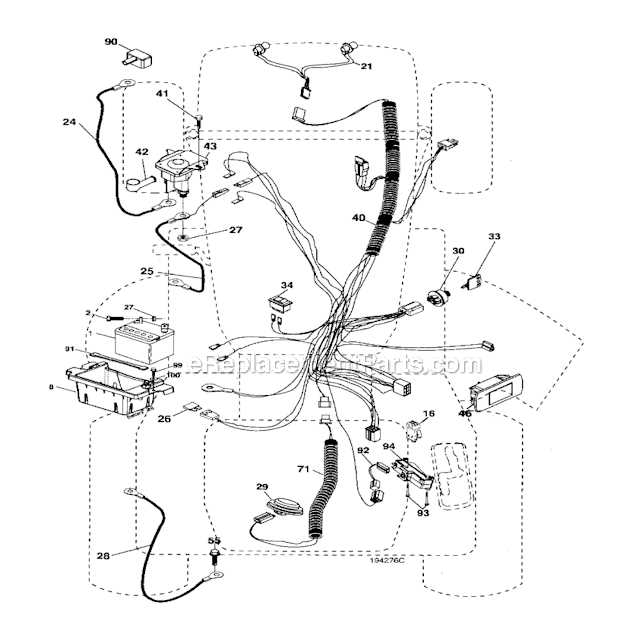

Step-by-Step Repair Guide

This guide provides a systematic approach to fixing common issues associated with lawn maintenance equipment. Whether you’re facing mechanical failures or general wear and tear, following these steps will help restore functionality effectively.

Before starting any repair, ensure you have the necessary tools and safety equipment on hand. This will facilitate a smoother process and minimize the risk of accidents.

| Step | Description |

|---|---|

| 1 | Identify the Problem: Examine the machine thoroughly to determine the source of the issue. |

| 2 | Gather Tools: Collect all required tools such as wrenches, screwdrivers, and safety gear. |

| 3 | Disconnect Power: Ensure the equipment is powered down and disconnected from any energy source. |

| 4 | Disassemble Components: Carefully remove the necessary parts to access the area needing repair. |

| 5 | Inspect for Damage: Check all components for signs of wear, cracks, or other issues that may need addressing. |

| 6 | Replace or Repair: Depending on the inspection, either replace damaged parts or make necessary repairs. |

| 7 | Reassemble: Put all parts back together in reverse order of disassembly, ensuring everything is secure. |

| 8 | Test the Equipment: Reconnect power and run the machine to ensure proper functionality. |

Following this methodical approach will enhance your chances of a successful repair, prolonging the life of your equipment and improving its performance.

Where to Find Replacement Parts

When your equipment requires new components, locating high-quality alternatives is essential for maintaining optimal performance. There are several reliable sources to consider when searching for these necessary items, ensuring you can quickly restore functionality without hassle.

Online Retailers

The internet offers a vast selection of platforms where you can find various components. Some of the most popular options include:

- Dedicated hardware and tool websites

- Major e-commerce platforms

- Specialized machinery retailers

These sites often provide detailed descriptions and customer reviews to assist in your selection.

Local Stores and Repair Shops

If you prefer a hands-on approach, visiting local establishments can be beneficial. Consider checking out:

- Home improvement centers

- Garden supply shops

- Independent repair facilities

These locations may also offer personalized assistance and advice on the best items for your specific needs.

Comparing YS4500 with Other Models

When evaluating various models within the same category, it’s essential to understand their distinct features and capabilities. This comparison highlights how each design stands out in terms of performance, usability, and overall efficiency.

- Performance: Different models offer varying levels of power, impacting speed and cutting ability.

- Durability: Material quality and construction methods play a significant role in longevity.

- User Experience: Ergonomics and ease of use can greatly affect user satisfaction and comfort.

In examining these aspects, consumers can make informed decisions based on their specific needs and preferences.

DIY vs. Professional Repair Options

When it comes to fixing machinery, individuals often face a choice between tackling repairs themselves or hiring skilled technicians. Each option presents its own set of benefits and challenges, impacting both the quality of work and cost-efficiency. Understanding these differences can help in making an informed decision tailored to specific needs.

Advantages of DIY Repairs

Taking on repairs independently can be both rewarding and cost-effective. Learning new skills and the satisfaction of completing a project can greatly enhance one’s confidence. Additionally, sourcing materials independently can lead to savings, allowing enthusiasts to delve into their hobbies without breaking the bank.

Benefits of Professional Services

On the other hand, enlisting professional assistance guarantees expertise and often a quicker turnaround. Experienced technicians are equipped with the necessary tools and knowledge to handle complex issues effectively. This can ultimately save time and reduce the likelihood of future problems, ensuring that the machinery operates at peak performance.

Tips for Long-lasting Performance

Ensuring the durability and efficiency of your equipment involves regular maintenance and thoughtful practices. By following a few key guidelines, you can extend the life of your machinery and maintain its peak functionality. This section highlights essential strategies to promote longevity and reliable operation.

Regular Maintenance Checks

Performing routine inspections is crucial. Examine all components for wear and tear, and promptly replace any damaged elements. Cleaning after use is also vital, as debris accumulation can hinder performance. Make it a habit to check fluid levels and ensure proper lubrication to prevent unnecessary friction and overheating.

Proper Storage and Handling

Store your equipment in a sheltered environment to protect it from harsh weather conditions. Use a cover if necessary, and avoid leaving it exposed to moisture. Handling machinery with care during operation minimizes the risk of damage. Follow recommended usage guidelines to ensure optimal performance without unnecessary strain on the system.