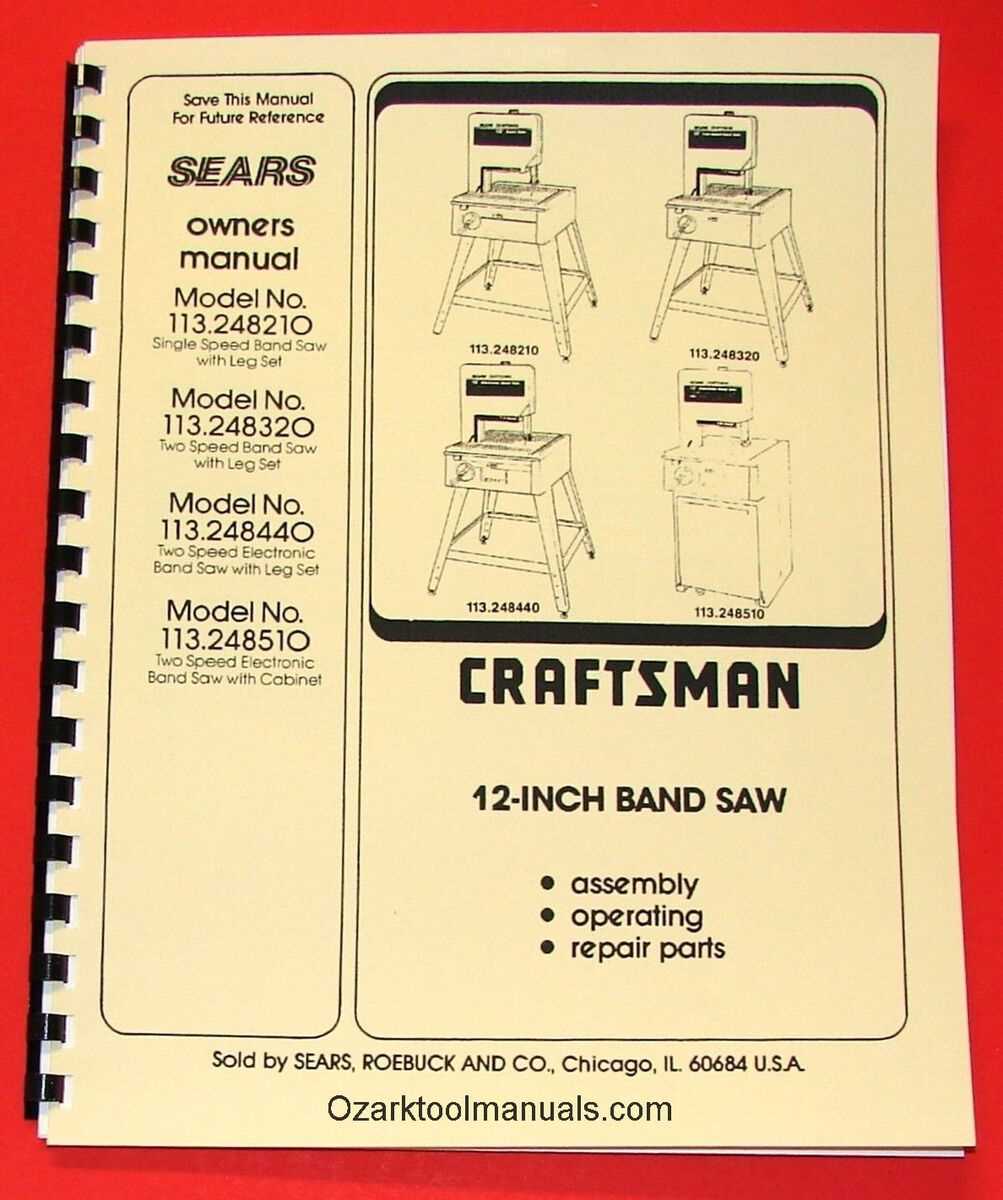

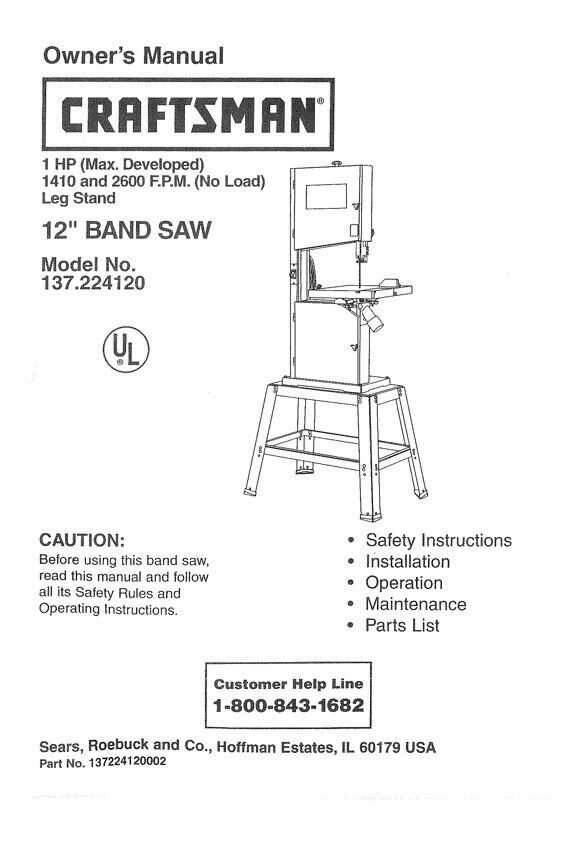

In the realm of woodworking and metalworking, the efficient operation of cutting equipment relies heavily on its individual components. Each element plays a crucial role in the overall functionality, ensuring precision and reliability during use. Familiarity with these pieces is essential for maintenance, troubleshooting, and enhancing performance.

When delving into the specifics of a cutting apparatus, one encounters various mechanisms that contribute to its effectiveness. From the motor to the guiding system, each section works harmoniously to facilitate seamless operation. Understanding these segments not only aids in optimal usage but also empowers users to identify potential issues before they escalate.

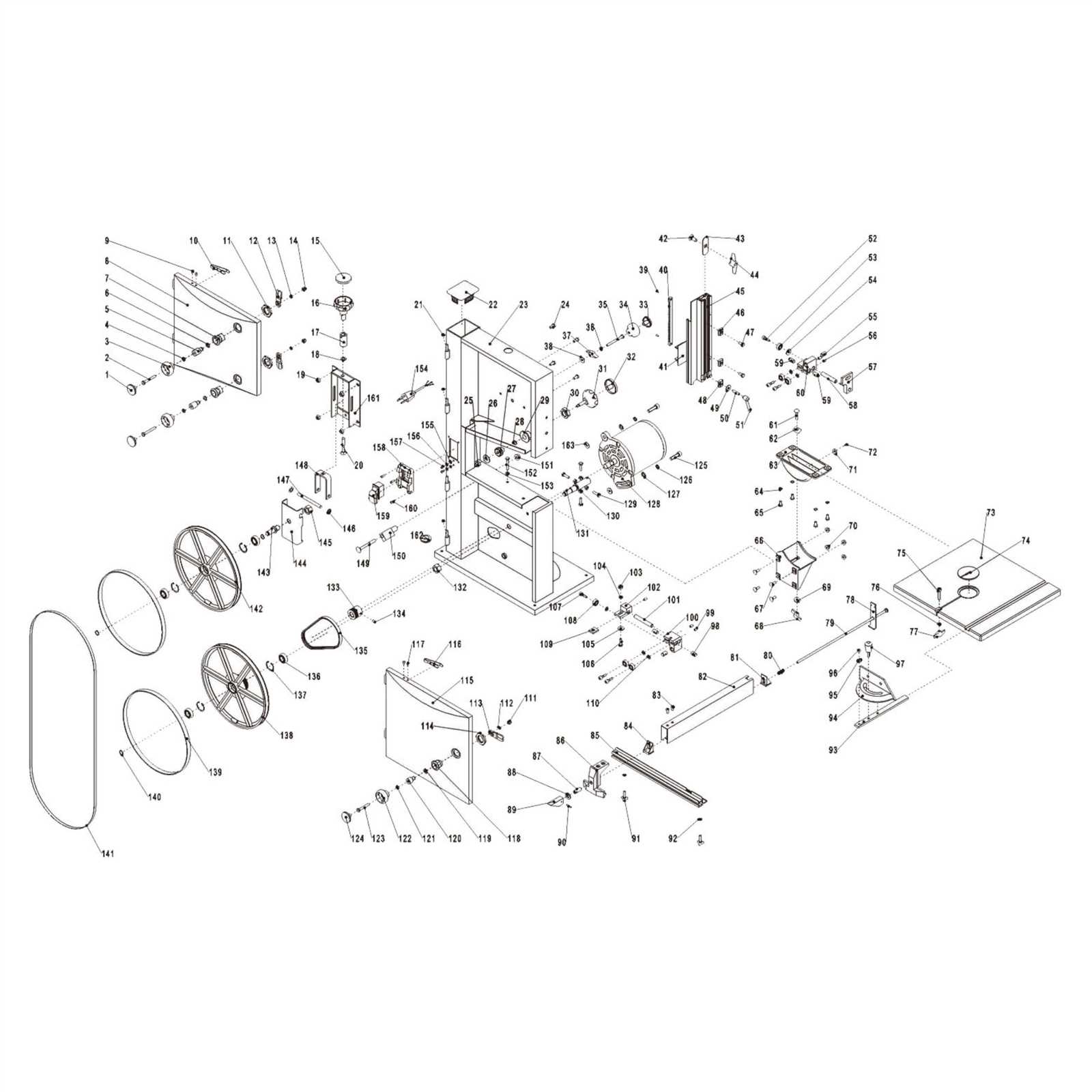

For enthusiasts and professionals alike, having a clear representation of these components can significantly simplify the repair and enhancement process. Visual aids serve as invaluable resources, providing clarity on how each part interconnects. By gaining insight into the layout of these elements, users can better appreciate the craftsmanship behind their tools and ensure they remain in peak condition.

Key Components of the Band Saw

Understanding the essential elements of a cutting tool is crucial for effective operation and maintenance. Each component plays a vital role in ensuring precision, safety, and durability. Here, we will explore the fundamental parts that make up this versatile machine.

- Frame: The sturdy structure supports all other elements, providing stability during operation.

- Motor: This powerhouse drives the cutting mechanism, determining speed and efficiency.

- Blade: The heart of the machine, designed to perform specific cutting tasks with accuracy.

- Table: A flat surface that supports the material being cut, often adjustable for various angles.

- Guide System: Keeps the blade aligned and reduces vibration for smoother cuts.

Each of these components contributes to the overall functionality, making it essential to maintain and understand them for optimal performance.

Importance of Accurate Parts Diagram

Having a precise representation of components is essential for effective maintenance and repair of machinery. Such visual guides enable users to identify individual elements swiftly, ensuring that any adjustments or replacements can be made with confidence. This accuracy not only streamlines the repair process but also enhances safety and efficiency in operations.

Facilitating Repairs

An accurate visual guide allows technicians to pinpoint the exact components that need attention. By clearly illustrating where each part is located, users can avoid common mistakes that lead to further damage or malfunction. This can significantly reduce downtime and costs associated with repairs, as well as minimize the risk of incorrect reassembly.

Enhancing User Knowledge

Detailed visual aids serve as educational tools for both novice and experienced users. By familiarizing themselves with the layout and function of each component, users gain a deeper understanding of the equipment they are working with. This knowledge empowers them to make informed decisions regarding upgrades, modifications, or troubleshooting.

| Benefits | Description |

|---|---|

| Time Efficiency | Reduces the time needed for maintenance by simplifying identification and access to components. |

| Cost Savings | Minimizes unnecessary expenditures on repairs through accurate assessment of required components. |

| Safety | Improves safety by ensuring proper handling and installation of components, reducing the risk of accidents. |

Common Issues with Band Saw Parts

In the realm of woodworking tools, various components may encounter problems that hinder performance and efficiency. Recognizing these common challenges is essential for maintaining optimal functionality and prolonging the lifespan of the equipment. By understanding potential failures, users can take proactive measures to ensure smooth operation and enhance safety during use.

Misalignment of the Blade

One prevalent issue is the misalignment of the cutting blade, which can result in inaccurate cuts and increased wear on the equipment. Regularly checking and adjusting the blade’s alignment can prevent complications, ensuring that it operates correctly and produces precise results.

Wear and Tear on Bearings

Another frequent concern is the deterioration of bearings, which can lead to increased friction and noise during operation. Over time, these components can wear down, affecting the overall performance of the tool. Regular maintenance and timely replacement of worn bearings are crucial to maintaining smooth operation and reducing the risk of further damage.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations provide a simplified view of various elements, allowing users to identify and locate each item with ease.

Key Components to Focus On

- Labels: Ensure you read the annotations carefully, as they clarify the function and placement of each item.

- Numbering System: Familiarize yourself with the numbering, which usually corresponds to a list of components or a manual.

- Lines and Arrows: Pay attention to connections and relationships indicated by lines and arrows, which depict how parts interact.

Tips for Effective Interpretation

- Start with an overview of the entire illustration before diving into specifics.

- Cross-reference with a list or manual to confirm your understanding.

- Take notes on any unclear items for further research or assistance.

Identifying Replacement Parts Easily

Finding the right components for your tools can often be a challenging task. However, understanding how to effectively identify and source these elements is crucial for maintaining the functionality of your equipment. By utilizing resources such as manuals, online databases, and community forums, you can streamline the process of locating the necessary items for repairs or upgrades.

Utilizing Visual References

One of the most effective methods for identifying the components you need is to consult visual aids. Diagrams and schematics serve as excellent references, providing a clear view of each individual element and its placement. This visual approach not only helps in pinpointing the exact item but also enhances your understanding of how each piece interacts within the system.

Resources for Sourcing Components

Once you have identified the required elements, the next step is to find reliable sources for procurement. There are several avenues to explore, including online retailers, local hardware stores, and manufacturer websites. It’s beneficial to compare prices and availability across different platforms to ensure you get the best deal.

| Source Type | Examples |

|---|---|

| Online Retailers | Amazon, eBay, Tool parts Direct |

| Local Stores | Home Depot, Lowe’s, Ace Hardware |

| Manufacturer Websites | Official company sites, Service centers |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and performance of your tools. By implementing a few key practices, you can enhance their lifespan and maintain optimal functionality, ultimately saving time and resources in the long run.

Regular Cleaning

Keeping your equipment clean is paramount. After each use, wipe down surfaces to remove dust and debris. Pay special attention to the internal components, as buildup can hinder performance. Use appropriate cleaning solutions and avoid harsh chemicals that could damage sensitive parts.

Lubrication and Adjustment

Frequent lubrication of moving parts minimizes friction and wear. Check the manufacturer’s guidelines for recommended lubricants and application intervals. Additionally, ensure that all settings and tensions are properly adjusted to enhance performance and prevent unnecessary strain on the machinery.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a crucial task, ensuring optimal performance and longevity. Whether you’re looking to replace worn-out elements or upgrade your machine, several resources are available to assist you in this endeavor.

Online Retailers

Numerous online platforms specialize in providing a wide range of components. Here are some reliable options:

- Manufacturer’s official website: Often the best source for authentic replacements.

- Dedicated tool supply websites: These sites frequently carry a vast selection of components for various brands.

- Marketplaces: Websites like Amazon and eBay can offer both new and used items at competitive prices.

Local Supply Stores

Visiting physical stores can also be beneficial. Consider checking out:

- Home improvement centers: Many of these stores maintain a good inventory of tools and accessories.

- Specialized hardware shops: These retailers often have knowledgeable staff who can assist you in finding the right components.

- Tool repair shops: These establishments can sometimes order specific parts directly from manufacturers.

By exploring these options, you can efficiently source the necessary components to keep your equipment running smoothly.