When the chilly season arrives, having a reliable machine for clearing pathways becomes essential. Knowing how every component functions ensures smooth operation and enhances the lifespan of your device. Familiarity with the assembly of your machine can transform a daunting task into a straightforward one.

In this section, we will explore the intricate details of each element within your equipment. By breaking down the individual components, you can identify the key features and mechanisms that contribute to optimal performance. This knowledge not only aids in maintenance but also empowers you to tackle any issues that may arise.

Whether you are a seasoned user or a newcomer, delving into the specifics can enhance your experience and provide the ultimate confidence in handling your machinery. Let’s dive into the details and ensure you are well-prepared for the snowy days ahead.

Understanding Cub Cadet Snow Blowers

When it comes to winter equipment designed for clearing pathways and driveways, having a solid grasp of the various components and their functions is essential. These machines are engineered to handle harsh conditions and effectively manage the accumulation of frost. By understanding their design and operation, users can optimize performance and enhance longevity.

Typically, these machines consist of several crucial elements, each contributing to their overall efficiency. Familiarity with these components not only aids in maintenance but also helps in troubleshooting common issues. Below is a table that outlines some of the key components and their functions.

| Component | Description |

|---|---|

| Auger | Helps in gathering and lifting the material to be cleared. |

| Chute | Directs the flow of the material once it is processed. |

| Engine | Powers the entire machine, enabling movement and operation. |

| Skid Shoes | Protect the base and assist in adjusting the height for different surfaces. |

| Drive System | Facilitates movement, allowing the machine to navigate through various terrains. |

By understanding these critical aspects, users can ensure their equipment remains effective and reliable throughout the winter season.

Key Components of Snow Blowers

Understanding the essential elements of winter clearing machines is crucial for efficient operation and maintenance. Each part plays a vital role in ensuring the effectiveness of these devices, especially during heavy snowfall. Familiarity with these components can help users troubleshoot issues and optimize performance.

Engine: The engine serves as the powerhouse, providing the necessary force to operate the entire mechanism. It is available in various types, including gas and electric, influencing the overall efficiency and convenience.

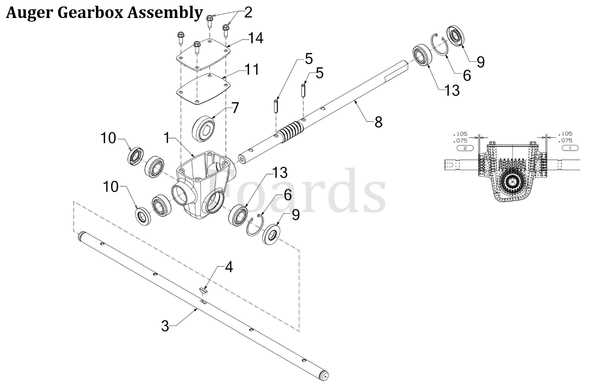

Auger: This rotating component is responsible for gathering and moving the frozen precipitation towards the discharge chute. Its design can vary, with some models featuring multiple blades for enhanced performance.

Chute: The chute directs the ejected material away from the machine. Adjustable chutes allow users to control the distance and angle of the discharge, making it easier to clear paths effectively.

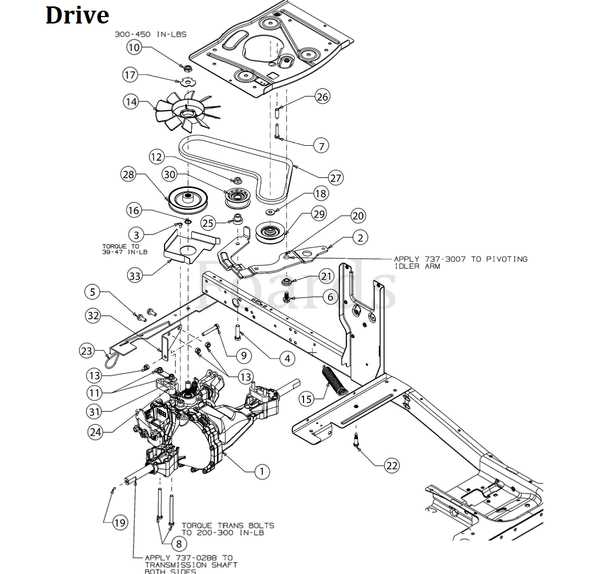

Drive System: This system powers the wheels or tracks, enabling mobility across different terrains. A robust drive mechanism is essential for tackling heavy accumulations and maintaining stability.

Controls: User-friendly controls allow for easy operation and adjustments. Features such as speed settings and chute direction controls enhance the overall user experience and adaptability to varying conditions.

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the extended lifespan of any machinery. By engaging in consistent care practices, one can prevent wear and tear, enhance performance, and reduce the risk of unexpected failures. A proactive approach allows users to identify potential issues before they escalate, leading to more efficient operation and lower repair costs.

Maintaining equipment not only preserves its functionality but also maximizes safety for the user. Well-maintained machines are less likely to malfunction, providing peace of mind during usage. Furthermore, it contributes to the overall efficiency, enabling the equipment to perform at its ultimate best when needed the most.

Incorporating a maintenance routine is an investment in the future of the machinery, as it fosters reliability and performance. Ultimately, a commitment to care translates into a longer, more productive life for any piece of equipment, ensuring it serves its purpose effectively over time.

Common Issues with Snow Clearing Equipment Components

Maintenance of winter machinery is essential for optimal performance. Various components can experience wear and tear, leading to potential malfunctions. Identifying these common challenges is crucial for ensuring reliability during harsh weather conditions.

Worn Out Belts and Cables

Over time, drive belts and control cables may become frayed or stretched. This can result in decreased efficiency and responsiveness. Regular inspection and timely replacement can prevent more significant issues and ensure smooth operation.

Clogged Mechanisms

Debris accumulation can obstruct the functioning of critical elements. Snow, ice, and other materials can hinder movement and cause overheating. Cleaning these areas frequently is vital for maintaining performance and extending the lifespan of the equipment.

How to Read a Parts Diagram

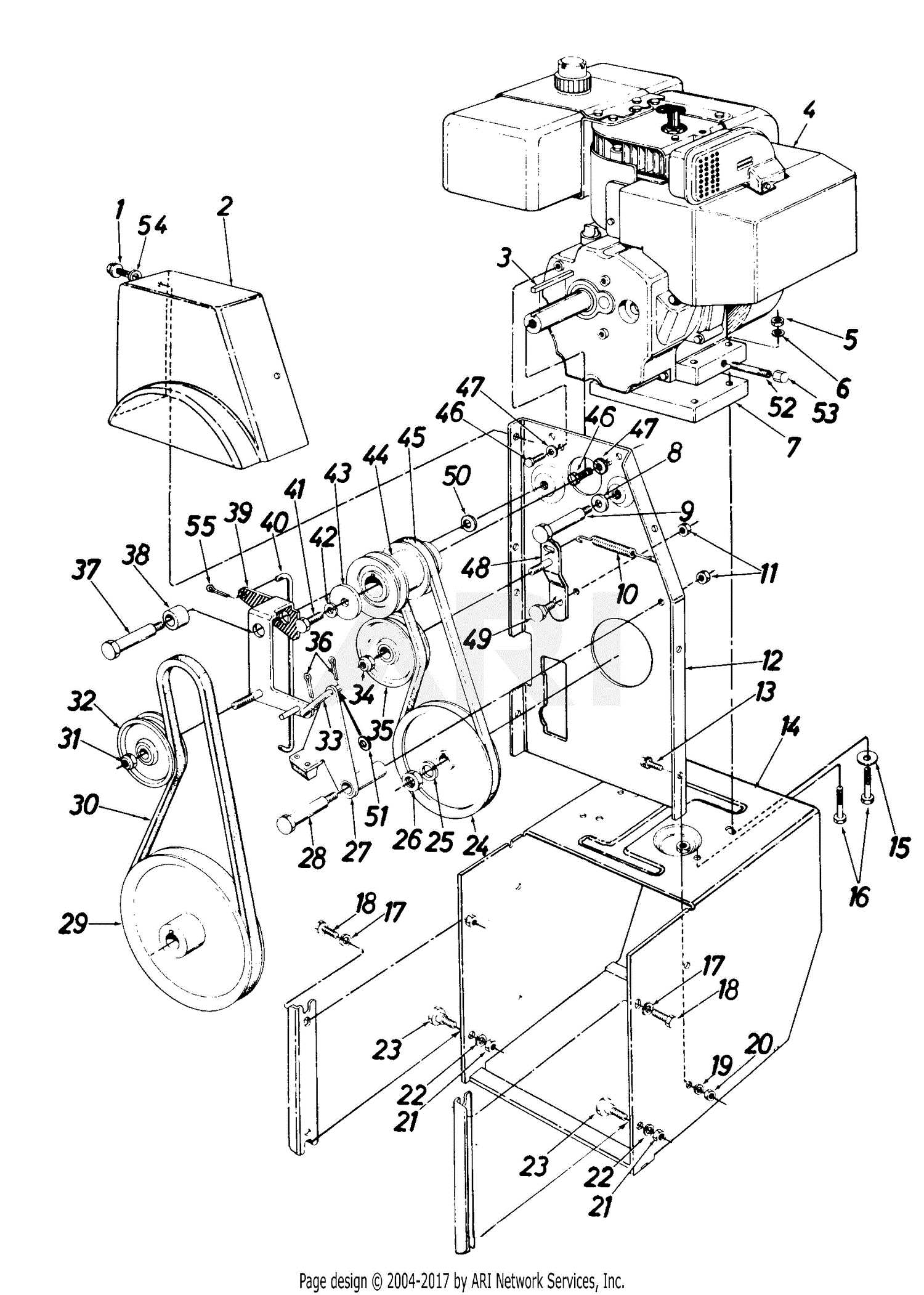

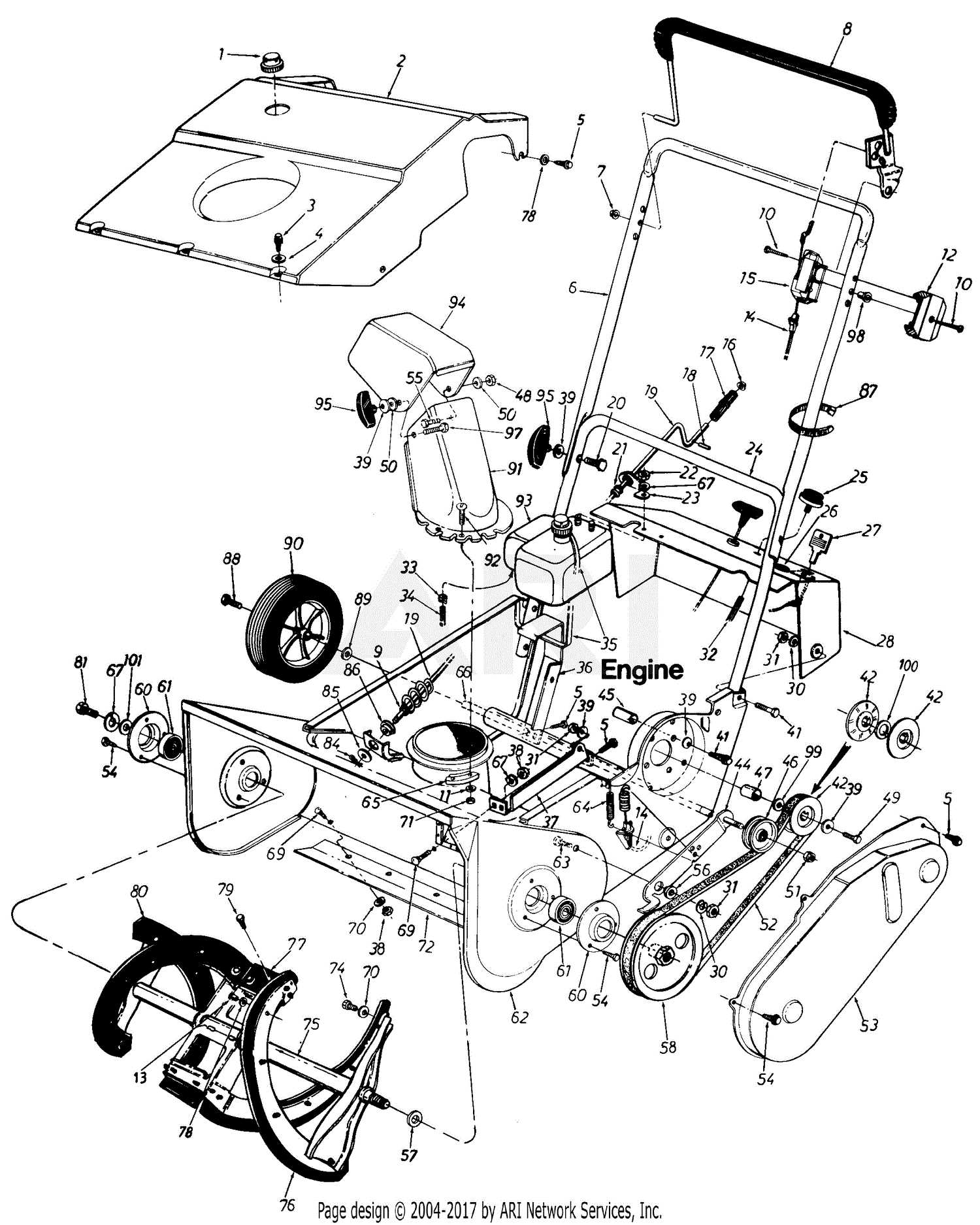

Understanding a schematic is essential for effective maintenance and repair. These illustrations serve as valuable references, showcasing the relationship between components and their placements within a machine. Familiarity with these visuals can streamline the troubleshooting process and facilitate the acquisition of necessary components.

Key Components of the Illustration

Begin by identifying the various sections of the graphic. Each element is typically labeled with a unique identifier or number. This allows users to easily cross-reference the illustration with accompanying documentation or catalogs to find specific components.

Interpreting Symbols and Labels

Pay close attention to the symbols and notations used within the schematic. Arrows may indicate movement or direction, while circles or squares often represent distinct parts. Color coding can also provide additional insights, highlighting different types of materials or functions within the system.

Where to Find Replacement Parts

Finding the right components for your equipment is crucial for maintaining its performance and longevity. Whether you’re in need of a specific item or a full set, knowing where to look can save time and money.

Online Retailers

- Official manufacturer websites

- Major e-commerce platforms

- Specialty retailers focused on outdoor equipment

Local Shops

- Authorized dealers in your area

- Hardware stores with a wide range of inventory

- Repair shops that may have spare items available

Assembly Tips for Snow Blower Parts

Proper assembly of your equipment can significantly enhance its performance and longevity. Understanding the relationship between different components is essential for effective operation, especially in challenging winter conditions. Here are some helpful suggestions to guide you through the process.

Preparation Steps

- Review the user manual thoroughly to familiarize yourself with each component.

- Gather all necessary tools to avoid interruptions during the assembly process.

- Organize all components systematically to streamline your workflow.

Assembly Guidelines

- Begin with the frame, ensuring all bolts are securely fastened.

- Attach the motor unit, checking alignment before tightening any screws.

- Connect the drive mechanism, making sure to follow the specified order in the manual.

- Install the auger system, verifying that all safety features are engaged.

- Finish with the chute assembly, ensuring it moves freely for optimal operation.

By following these guidelines, you can achieve a successful assembly that maximizes efficiency and minimizes potential issues during use.

DIY Repairs: What You Need to Know

Engaging in home repairs can be a rewarding experience, allowing you to save money and gain valuable skills. Understanding the basic components of your equipment and how they work together is crucial for effective maintenance. This knowledge empowers you to tackle issues confidently and enhances your ability to perform necessary fixes without professional assistance.

Before starting any repair, it’s essential to gather the right tools and resources. Familiarize yourself with the user manual, which typically contains troubleshooting tips and detailed information on the system’s layout. Utilizing online resources, such as instructional videos or forums, can provide additional insights and guidance from experienced users.

Safety should always be a priority. Ensure you wear appropriate protective gear and disconnect power sources when working on equipment. Taking the time to prepare adequately will help prevent accidents and ensure a smoother repair process.

When diagnosing a problem, systematically check each component. Identify any signs of wear or damage and replace parts as needed. Keeping track of your progress and documenting the steps taken can also be beneficial for future repairs or for others who may encounter similar issues.

With practice and patience, you can become proficient at maintaining your equipment. Embrace the learning curve, and remember that each repair enhances your understanding and capability for future projects.

Choosing the Right Model for Your Needs

Selecting the ideal machinery for winter maintenance requires careful consideration of various factors. The right choice can enhance efficiency and performance, ensuring that you tackle the challenges of the season effectively.

Here are key aspects to evaluate:

- Size of Area: Assess the dimensions of the area you need to clear.

- Snow Conditions: Consider the typical snowfall amounts and the type of snow.

- Power Source: Decide between gas or electric options based on convenience and availability.

- Features: Look for specific functionalities like adjustable speeds and throw distance.

- Budget: Set a budget that aligns with your expectations and needs.

Delve into these criteria to find the ultimate model that meets your specific requirements.