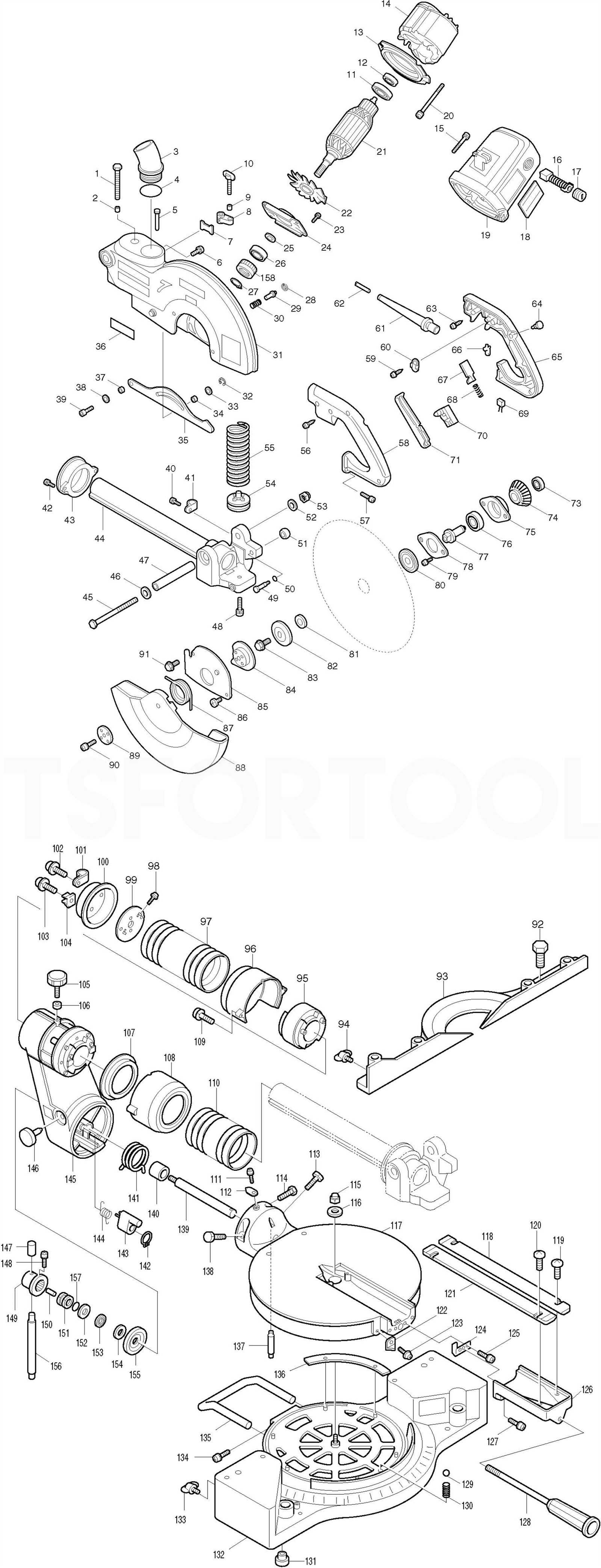

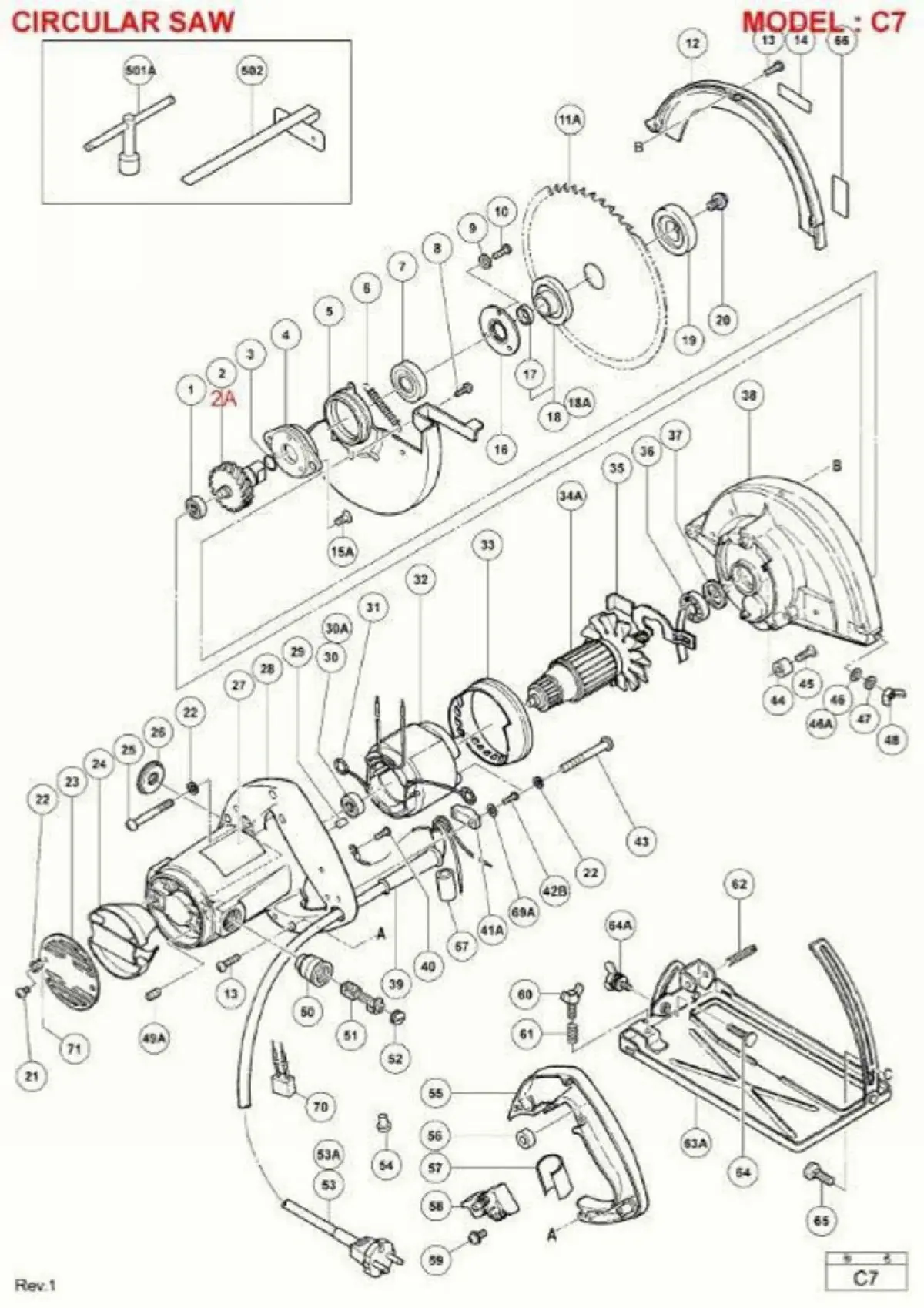

When it comes to mastering the intricacies of power tools, having a clear visual representation of their essential elements is invaluable. This understanding not only enhances repair skills but also facilitates effective maintenance, ensuring optimal performance.

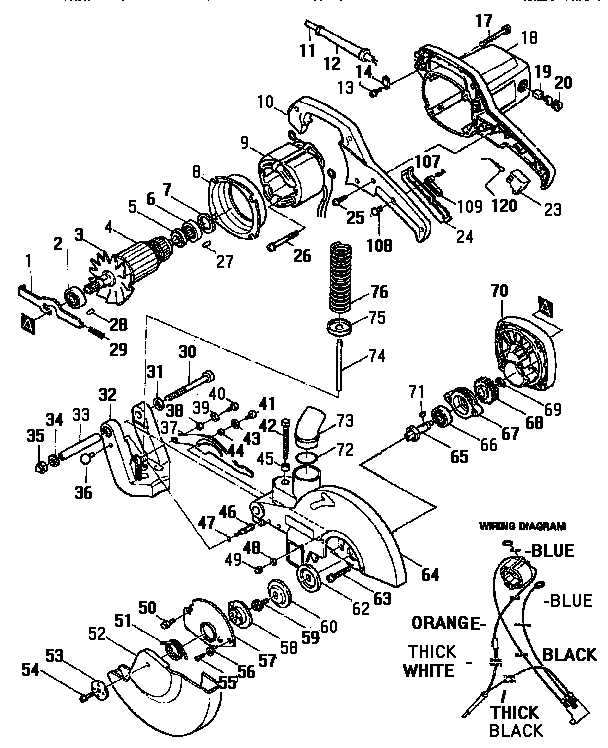

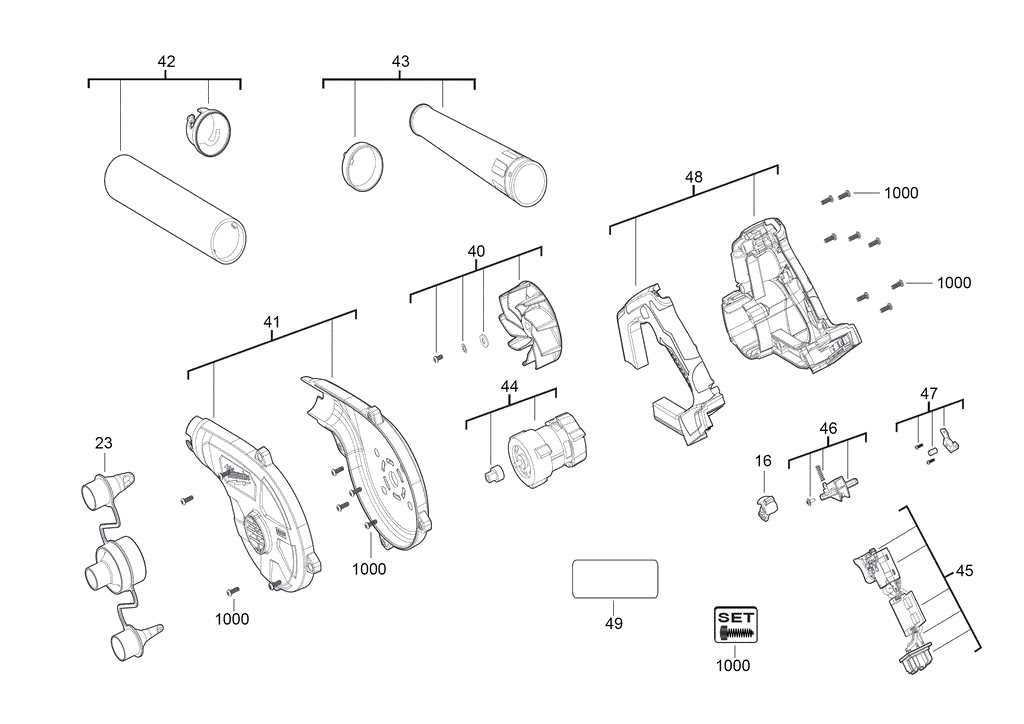

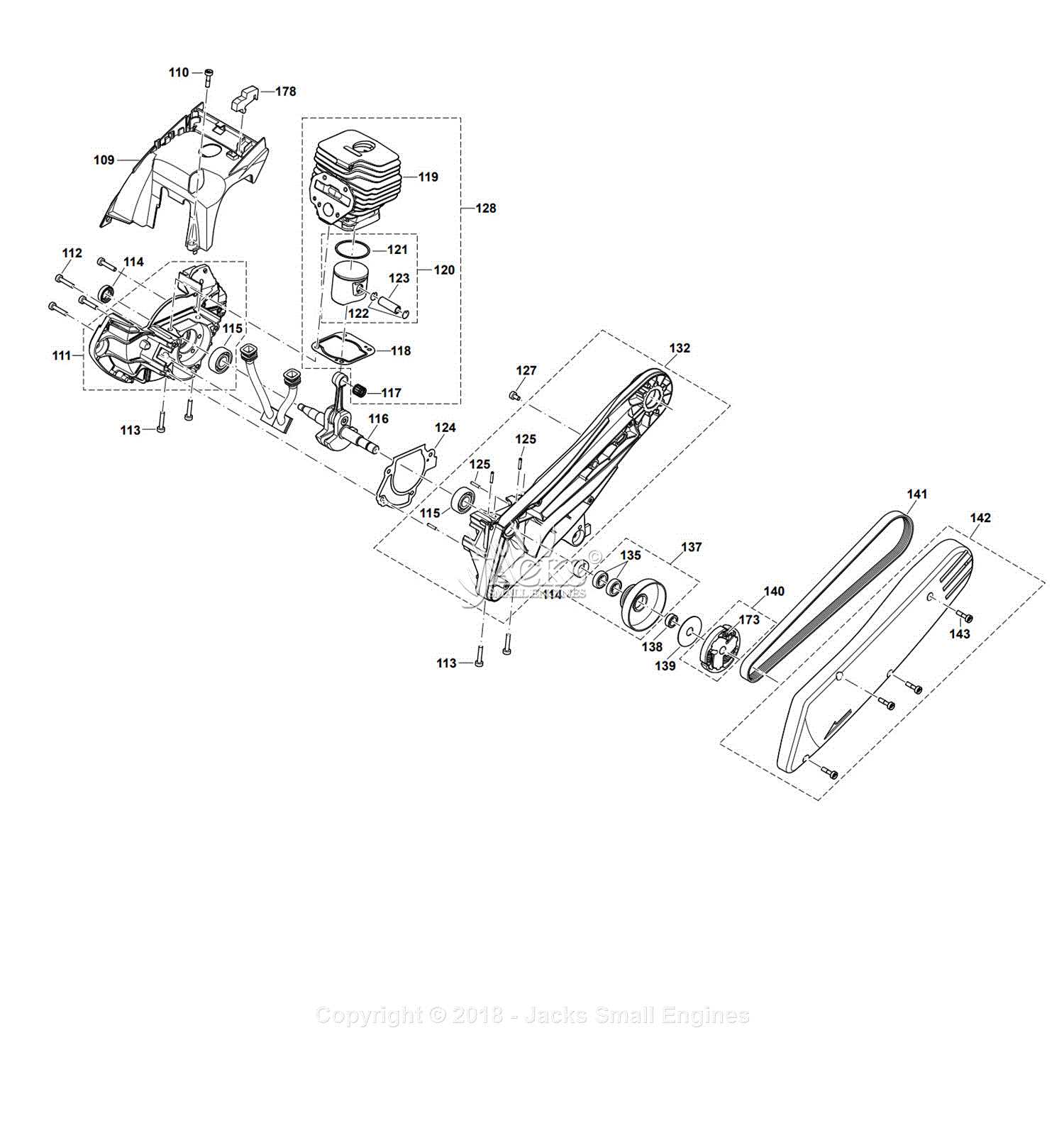

Each component plays a critical role in the functionality and efficiency of the equipment. By examining a detailed illustration of these parts, users can easily identify potential issues and learn how each segment contributes to the overall operation.

Furthermore, this knowledge empowers users to delve deeper into their tools, enabling informed decisions regarding upgrades and replacements. Ultimately, a comprehensive grasp of the inner workings leads to a more rewarding experience with any mechanical device.

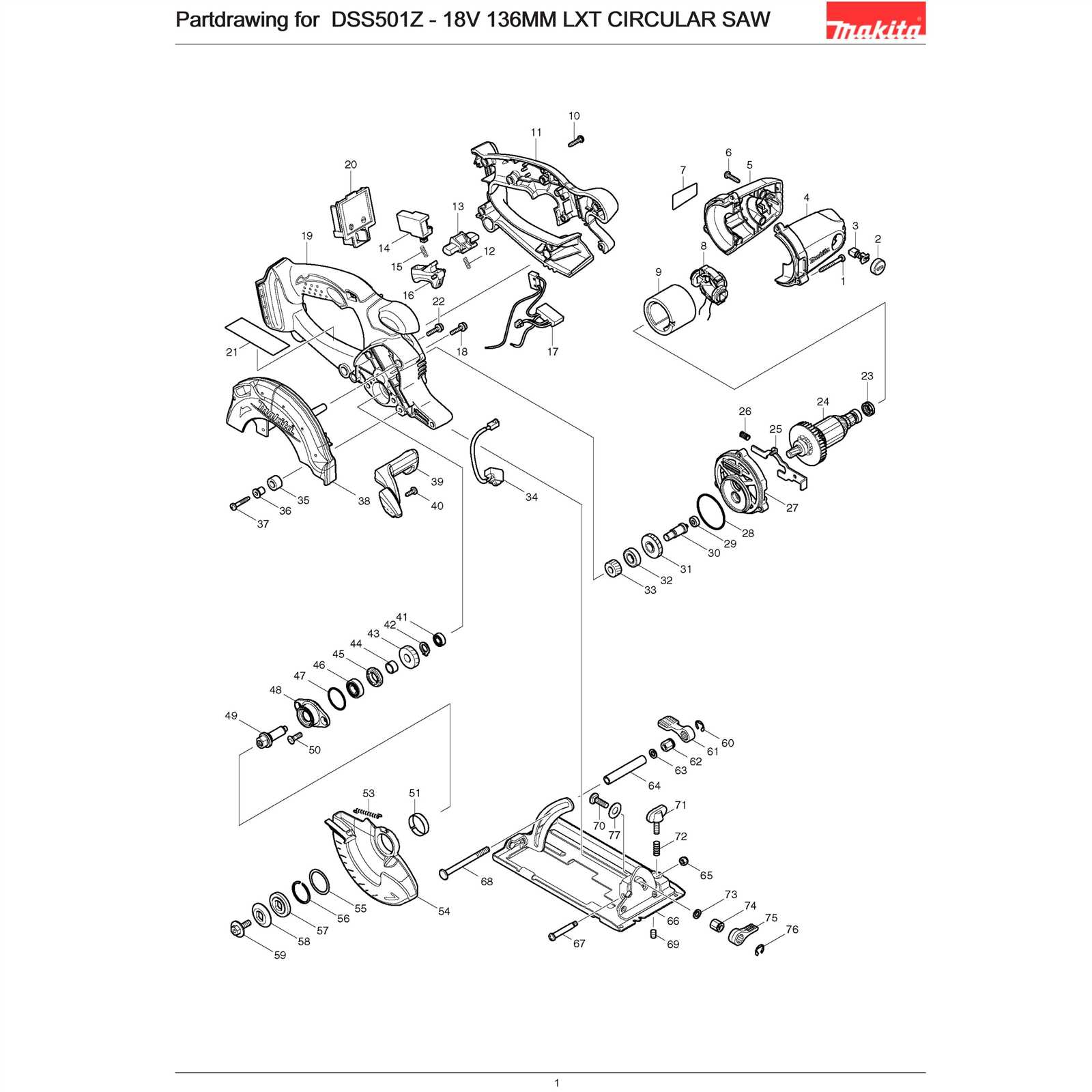

Understanding Makita Circular Saw Components

Grasping the essential elements of a power cutting tool is crucial for effective operation and maintenance. Each component plays a significant role in the functionality and performance of the machine, ensuring that it delivers precise cuts and operates safely. Familiarity with these elements can enhance user experience and longevity of the tool.

Main Elements of the Tool

There are several key components that contribute to the overall efficiency of the machine. Understanding their functions can help users troubleshoot issues and perform maintenance when necessary.

| Component | Function |

|---|---|

| Motor | Provides power for cutting through various materials. |

| Blade | Engages with the material to create precise cuts. |

| Base Plate | Stabilizes the tool during operation and guides the cutting process. |

| Guard | Enhances safety by covering the blade when not in use. |

Additional Components for Efficiency

In addition to the primary elements, various supplementary components contribute to the overall performance and usability of the equipment. Recognizing these elements can assist users in optimizing their cutting tasks.

| Additional Component | Benefit |

|---|---|

| Depth Adjustment Lever | Allows for easy modification of cutting depth for different materials. |

| Bevel Adjustment Mechanism | Enables angled cuts for versatility in projects. |

| Dust Blower | Keeps the cutting line clear for improved visibility. |

| Handle | Provides grip and control during operation, enhancing user comfort. |

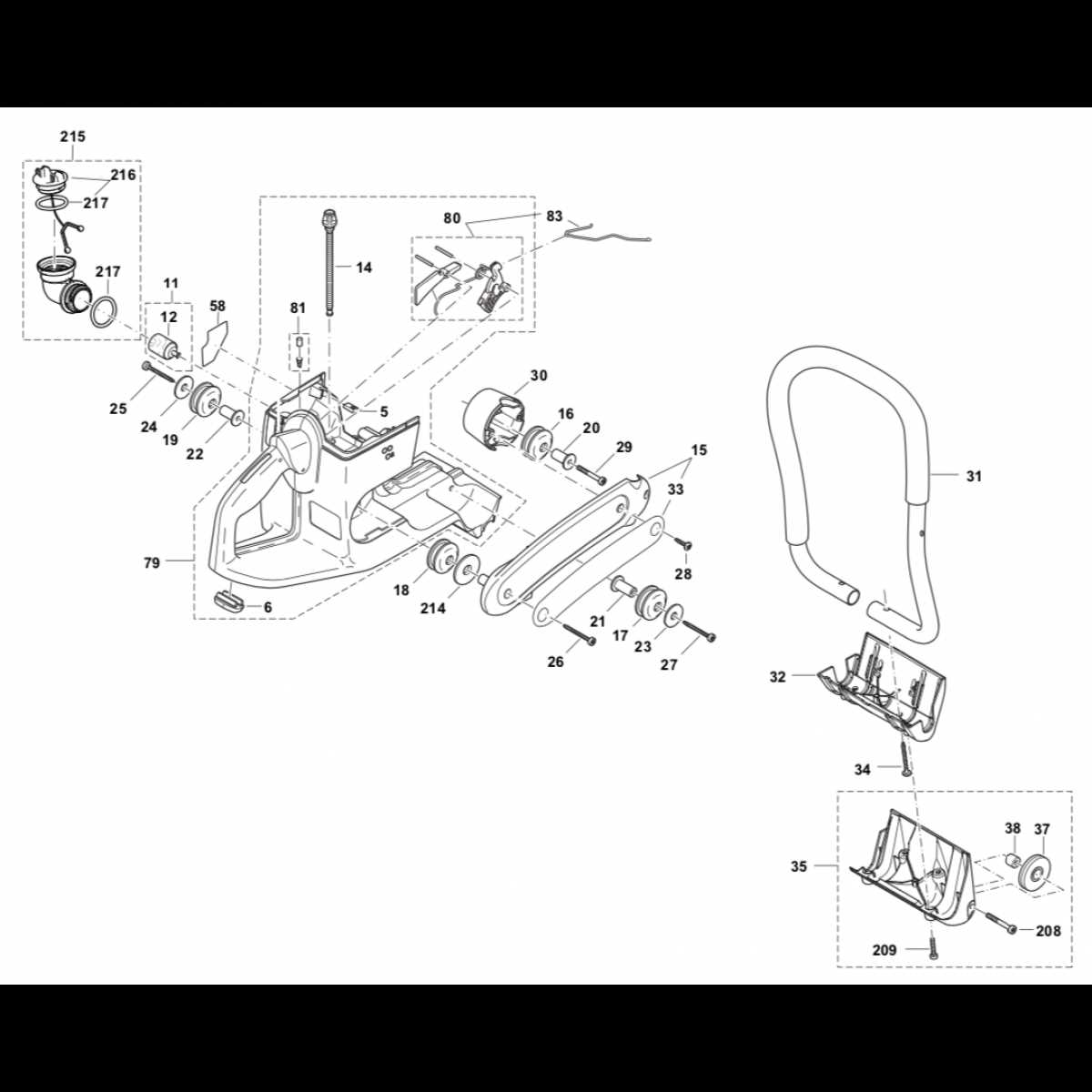

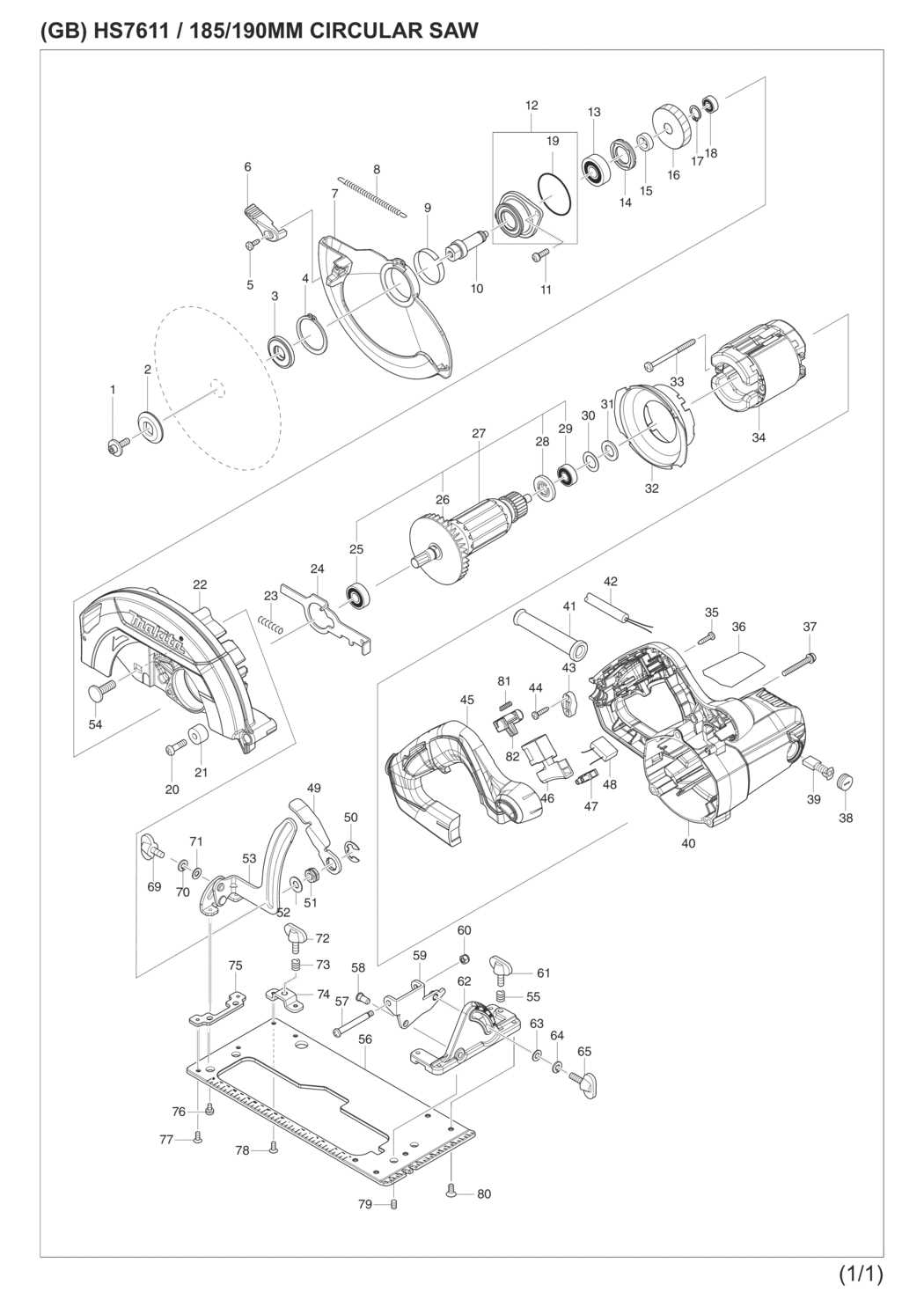

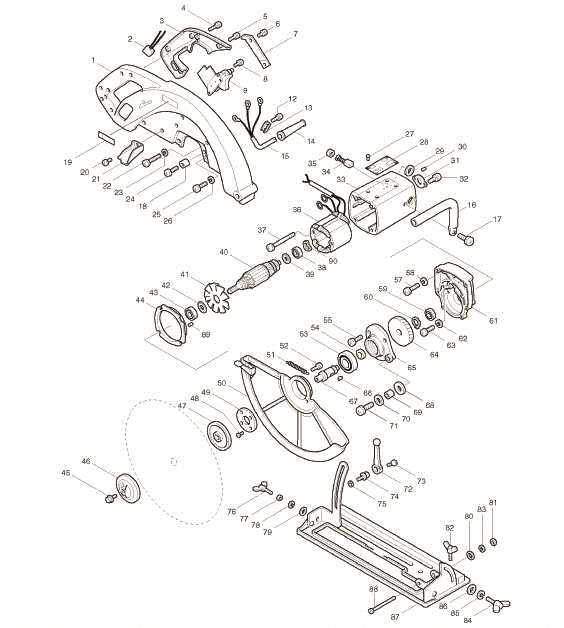

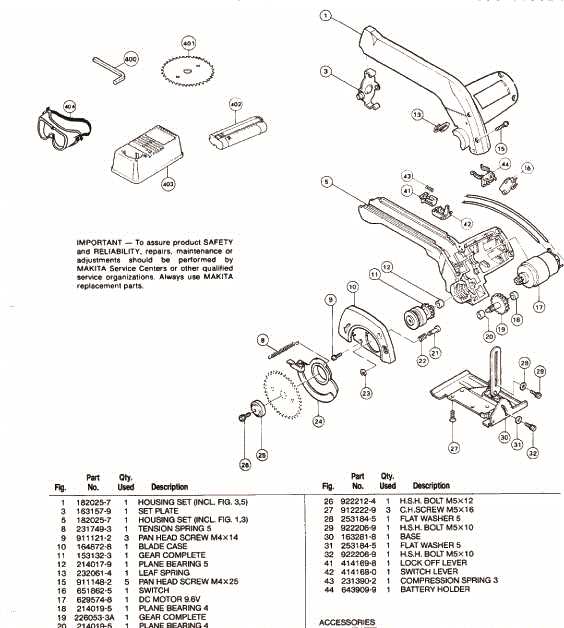

Exploring the Parts Diagram Overview

Understanding the structure of a tool is essential for efficient maintenance and repair. This section delves into the visual representation of components, offering insights into their arrangement and functionality. By familiarizing yourself with these elements, you can enhance your knowledge and improve your skills in tool management.

Key Components and Their Functions

Each segment of the illustration plays a pivotal role in the overall operation. Here are some crucial elements typically highlighted:

- Motor Assembly: Provides the necessary power for operation.

- Blade Holder: Secures the cutting edge in place.

- Base Plate: Offers stability and support during use.

- Adjustable Handle: Ensures comfort and control.

Benefits of Familiarization

Gaining insight into the configuration yields several advantages:

- Improved troubleshooting abilities.

- Increased efficiency in repairs and replacements.

- Enhanced safety during operation.

- Better understanding of tool upgrades and accessories.

In summary, a thorough grasp of the illustrated components significantly contributes to the effective utilization and longevity of your equipment.

Key Functions of Each Component

Understanding the essential roles played by various elements in a cutting tool is crucial for effective operation and maintenance. Each component contributes uniquely to the overall functionality, ensuring precision and safety during use.

Primary Components and Their Roles

- Blade: The heart of the tool, responsible for making clean and accurate cuts through materials.

- Motor: Provides the necessary power to rotate the blade at high speeds, enabling efficient cutting performance.

- Base Plate: Offers stability and support, helping to maintain the tool’s balance during operation.

- Guard: A protective feature that shields users from potential injuries while the tool is in use.

- Handle: Ensures a secure grip, allowing for better control and maneuverability.

Supporting Components

- Trigger: Activates the motor and blade, allowing for user control over the cutting process.

- Depth Adjustment Mechanism: Enables the user to set the cutting depth according to the material thickness.

- Dust Blower: Keeps the cutting line clear of debris, improving visibility and precision.

- Bevel Adjustment: Allows for angled cuts, adding versatility to the tool’s capabilities.

Each component plays a vital role, contributing to the effectiveness and safety of the entire apparatus. Familiarity with these functions enhances both the user experience and the longevity of the tool.

How to Read the Diagram Effectively

Understanding a technical illustration can be challenging, but it is crucial for successful maintenance and repairs. Familiarity with the layout and components can significantly enhance your efficiency. By mastering a few essential techniques, you can navigate the visual guide with confidence.

Start with the Legend: Most illustrations include a legend or key that defines symbols and numbers. Familiarize yourself with these elements to grasp the meaning behind the visual representations. This foundational step is essential for accurate interpretation.

Identify Major Components: Focus on the primary elements first. These are typically the larger sections of the illustration. By isolating these components, you can better understand their relationships and functions within the overall assembly.

Follow the Flow: Many illustrations are designed to depict the sequence of assembly or operation. Pay attention to arrows and lines that indicate movement or connection. Following this flow can help you visualize how parts interact and function together.

Take Notes: As you study the illustration, jot down important points or observations. This can aid retention and provide a quick reference when you begin your work. It’s a helpful practice that allows for a more hands-on approach to learning.

Refer to the Manual: If available, use the accompanying manual for additional context. The manual often contains descriptions and troubleshooting tips that can enhance your understanding of the illustration and its practical application.

Common Issues with Circular Saw Parts

Understanding frequent challenges related to tool components is essential for maintaining optimal performance and safety. Various elements can wear out or malfunction, leading to decreased efficiency and potential hazards during use. Identifying these issues early can help prevent larger problems down the line.

Worn Blades

Blades that are dull or damaged can lead to poor cutting results, increased strain on the motor, and potential kickback. Regular inspection and timely replacement are crucial for effective operation.

Electrical Failures

Electrical components may suffer from wear or damage, resulting in power loss or inconsistent performance. Ensuring connections are secure and checking for frayed wires can mitigate these risks.

Maintenance Tips for Longevity

Ensuring the durability of your cutting tool requires regular attention and care. By following a few essential practices, you can significantly extend the lifespan of your equipment and maintain its performance over time.

1. Regular Cleaning: After each use, take the time to clean your device thoroughly. Remove any debris, dust, or residue that may accumulate, as this can hinder functionality and lead to premature wear.

2. Proper Lubrication: Ensure that all moving components are adequately lubricated. This reduces friction and prevents overheating, which can cause significant damage if neglected.

3. Check for Wear: Periodically inspect your tool for signs of wear and tear. Replace any worn parts promptly to avoid further damage and maintain optimal performance.

4. Store Correctly: When not in use, store your equipment in a dry, safe place. Avoid exposure to extreme temperatures or moisture, as these conditions can deteriorate the materials.

5. Use Appropriate Accessories: Always utilize the correct attachments and accessories designed for your specific model. Using incompatible parts can lead to malfunctions and reduced efficiency.

By incorporating these practices into your routine, you can ensure that your cutting instrument remains reliable and effective for years to come.

Replacement Parts: Where to Find Them

Finding suitable components for your tools is essential for maintaining their performance and longevity. There are several reliable sources where you can explore options for acquiring these necessary items, ensuring your equipment remains in top condition.

Authorized Dealers

Visiting authorized retailers guarantees access to genuine components designed specifically for your model. These dealers often provide expert advice and can assist in identifying the correct replacements you need.

Online Marketplaces

Numerous online platforms offer a vast selection of items, often at competitive prices. Be sure to check seller ratings and reviews to ensure quality. Additionally, forums and community groups can be valuable resources for recommendations on where to purchase specific components.

Upgrades for Enhanced Performance

Improving the efficiency and functionality of your cutting tool can significantly impact your projects. Upgrading specific components not only enhances the performance but also extends the lifespan of the equipment. Investing in high-quality accessories can lead to smoother operation and increased precision, ensuring that every cut meets your expectations.

One of the most effective modifications involves replacing the standard blade with a high-performance variant. Opting for blades designed for specific materials can yield cleaner cuts and reduce wear on the tool. Additionally, considering a more powerful motor can provide increased torque and speed, allowing for quicker completion of tasks without sacrificing quality.

Enhancements in the base plate or shoe can also improve stability and accuracy during use. A robust, adjustable base enables better control, especially when working on uneven surfaces. Furthermore, integrating dust collection systems can enhance visibility and cleanliness in the workspace, contributing to a safer working environment.

Lastly, ergonomic upgrades, such as improved handles and grips, can greatly enhance user comfort. Reducing fatigue during extended use not only increases productivity but also ensures better safety. Investing in these upgrades can transform your tool into a more reliable and effective asset for any cutting endeavor.

Safety Considerations When Using Saws

Ensuring safety while operating cutting tools is paramount for both novice and experienced users. Proper precautions not only protect the individual but also enhance the overall efficiency of the task at hand. By adhering to established guidelines, one can minimize the risk of accidents and injuries.

Protective Gear: Always wear appropriate personal protective equipment, such as safety goggles, gloves, and ear protection. This gear acts as a barrier against flying debris and excessive noise, safeguarding your health during operation.

Work Environment: Maintain a clean and organized workspace. Clutter can lead to accidents; ensure that the area is free from obstacles and that all tools are within reach but out of the way of cutting paths.

Tool Maintenance: Regularly inspect and maintain your equipment. Ensure blades are sharp and properly aligned, as dull or misaligned tools can cause increased resistance and unexpected movements, leading to potential harm.

Technique: Employ correct techniques when using cutting instruments. This includes maintaining a firm grip and proper stance. Avoid distractions and focus on the task to reduce the likelihood of mistakes.

Emergency Procedures: Familiarize yourself with emergency protocols. Know how to quickly shut down your tools and have a first aid kit readily accessible. Being prepared can significantly reduce response time in the event of an incident.