Understanding the arrangement and core elements of a motorized garden tool can significantly improve its maintenance and longevity. Each component plays a crucial role in ensuring smooth operation and efficient performance. Regular inspection of the system helps identify any potential issues early, allowing for timely repairs or replacements.

In this section, we will explore the main elements that contribute to the operation of such a machine. By recognizing how these components interact, you can optimize the machine’s functionality and keep it running effectively for years to come.

Whether you’re looking to replace an individual element or simply enhance your knowledge about the tool’s configuration, having a clear understanding of its structure is essential. Proper care and occasional upgrades will ensure that your equipment remains reliable over time.

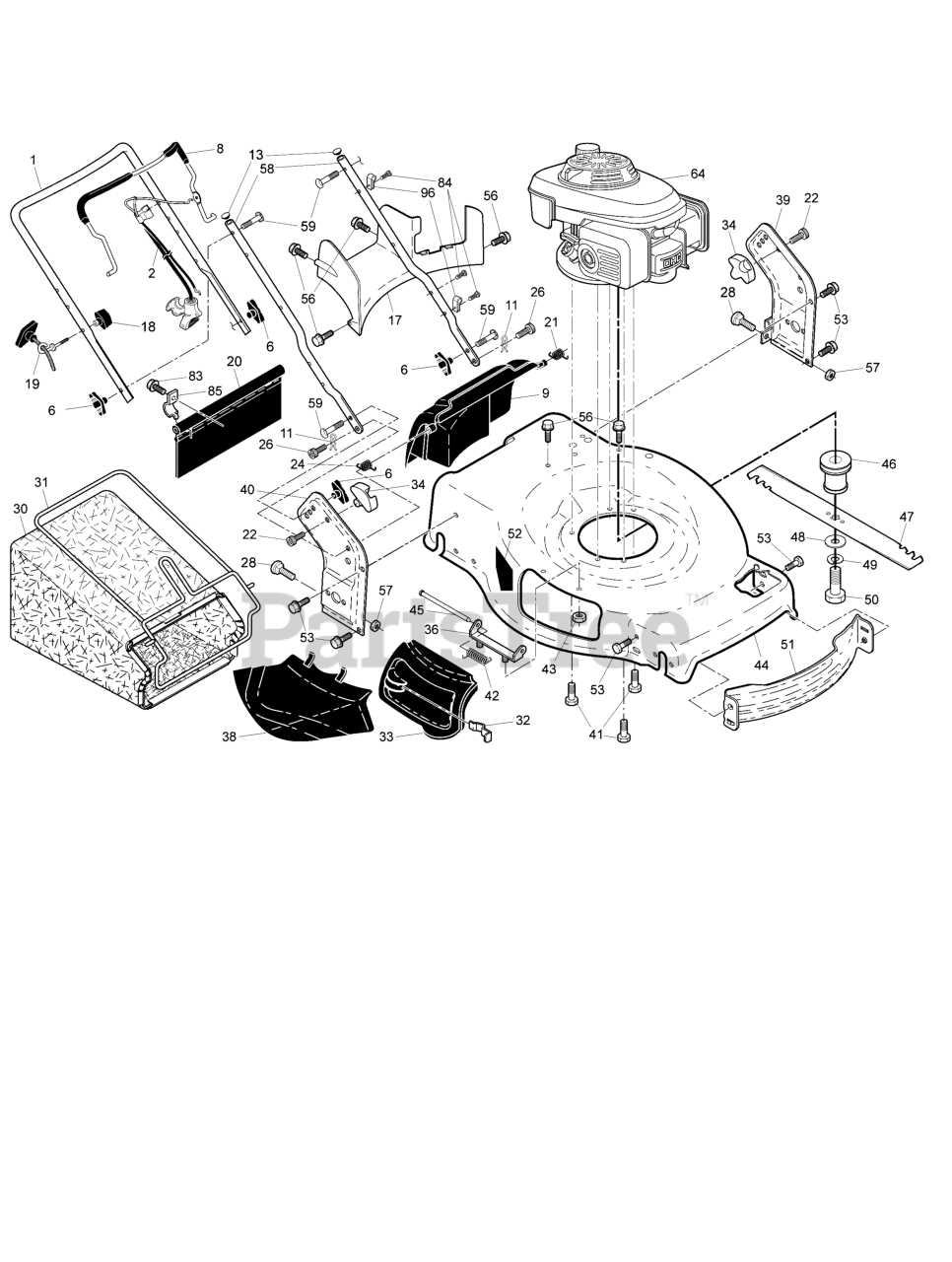

Key Components of a Walk-Behind Mower

The functionality and efficiency of this type of garden equipment depend on several crucial elements working together. Each part plays a significant role in ensuring smooth operation, durability, and ease of use, making it essential to understand their individual contributions.

Power System

- Engine: The core element providing the energy required for movement and cutting.

- Fuel Tank: Stores the fuel necessary for the engine to function effectively.

- Throttle Control: Allows the operator to manage the engine speed, providing control over cutting conditions.

Cutting and Control Mechanisms

- Blade Deck: Houses the cutting blades, responsible for trimming vegetation.

- Height Adjustment Lever: Enables users to modify the blade height for different cutting needs.

- Handlebars: Provide steering control and maneuverability for the user during operation.

- Wheels: These ensure smooth movement and stability over various terrains.

- Discharge Chute: Directs the clippings either to a collection bag or back onto the ground.

Understanding the Self-Propelled Mechanism

The driving system of this type of outdoor equipment offers users enhanced efficiency, reducing the physical effort needed to operate it. Instead of relying solely on manual force, a mechanical component assists in moving the equipment forward. This allows for smoother operation, even on uneven terrain or larger areas, significantly improving the overall experience.

How the Drive System Works

The core of the propulsion system is based on an integrated motor connected to the wheels. The engine transfers power to the drivetrain, which in turn moves the equipment without requiring continuous pushing. By controlling the speed through a lever or throttle, the operator can easily adjust the movement, providing a customizable and comfortable workflow.

Key Components of the Mechanism

Key elements of this system include the transmission, drive belt, and wheels. The transmission handles the conversion of engine power to motion, while the drive belt connects this power to the wheels. Proper maintenance of these components ensures reliable performance and prevents breakdowns.

Engine Parts and Their Maintenance

The internal components of the power unit play a crucial role in ensuring efficient and smooth operation. Regular attention to these elements is vital for prolonged functionality and optimal performance. Proper care and periodic inspection help avoid potential issues and keep the machine running at its best.

Key Engine Components

Some of the main elements include the cylinder head, spark plug, and the air filter. The cylinder head houses critical parts, while the spark plug ignites the fuel mixture to power the system. The air filter ensures the engine receives clean air, preventing damage from debris.

Maintenance Tips

Routine tasks such as cleaning or replacing the air filter, checking the spark plug, and ensuring proper lubrication can greatly extend the life of the engine. It is recommended to follow manufacturer guidelines for service intervals and use only appropriate tools for each component to prevent unnecessary wear or damage.

Blade System Overview and Care Tips

The blade system plays a crucial role in maintaining a well-groomed outdoor space. Understanding its components and maintenance is essential for optimal performance.

Key Components:

- Blades: Responsible for cutting grass evenly.

- Spindle Assembly: Supports and rotates the blades.

- Deck: Houses the blade system and provides airflow for efficient cutting.

Maintenance Tips:

- Regularly inspect blades for wear and damage.

- Sharpen blades every 20-25 hours of use to ensure clean cuts.

- Clean the deck after each use to prevent grass buildup.

- Check spindle assembly for proper lubrication and function.

- Replace damaged components promptly to maintain efficiency.

How the Drive Belt Powers the Mower

The drive belt is a crucial component that enables effective movement and operation of the machine. It transmits power from the engine to the wheels, allowing for smooth and controlled motion across various terrains.

Functionality of the Drive Belt

When the engine is activated, it generates rotational force. This force travels through the drive belt, which is designed to withstand tension and friction. As the belt engages with the pulleys, it converts the engine’s energy into kinetic energy, propelling the device forward.

Maintenance for Optimal Performance

To ensure longevity and efficiency, regular inspection of the drive belt is essential. Look for signs of wear or damage, and replace it if necessary. A well-maintained belt guarantees the ultimate performance of your equipment, making it essential for optimal functionality.

Wheels and Drive Assembly Insights

The functionality of a cutting machine relies heavily on its wheel and drive components. Understanding how these elements interact is crucial for optimal performance and maintenance. This section delves into the intricacies of these assemblies, highlighting their importance in the overall mechanism.

| Component | Description | Function |

|---|---|---|

| Wheels | Rubberized fittings designed for traction | Facilitate movement across various terrains |

| Drive Belt | Flexible band connecting engine to wheels | Transmits power to enable movement |

| Axles | Cylindrical rods supporting wheel rotation | Provide stability and allow wheels to turn |

| Gear Assembly | Interconnected gears regulating speed | Adjusts motion for efficiency |

Regular inspection and maintenance of these components can enhance longevity and ensure the ultimate functionality of the machine. Proper care will prevent common issues that could disrupt operation.

Fuel System: Common Issues and Fixes

The fuel mechanism is crucial for optimal engine performance, yet it can encounter various challenges that hinder operation. Identifying and resolving these problems is essential for maintaining efficiency and longevity.

Common Problems

| Issue | Description |

|---|---|

| Clogged Fuel Filter | Restricts fuel flow, leading to poor engine performance. |

| Old or Contaminated Fuel | Can cause starting issues and rough operation. |

| Damaged Fuel Lines | Leads to leaks and inconsistent fuel delivery. |

Recommended Fixes

To address these concerns, regularly inspect and replace the fuel filter, use fresh fuel, and check for any damage to fuel lines. These maintenance practices can significantly enhance functionality and prevent further complications.

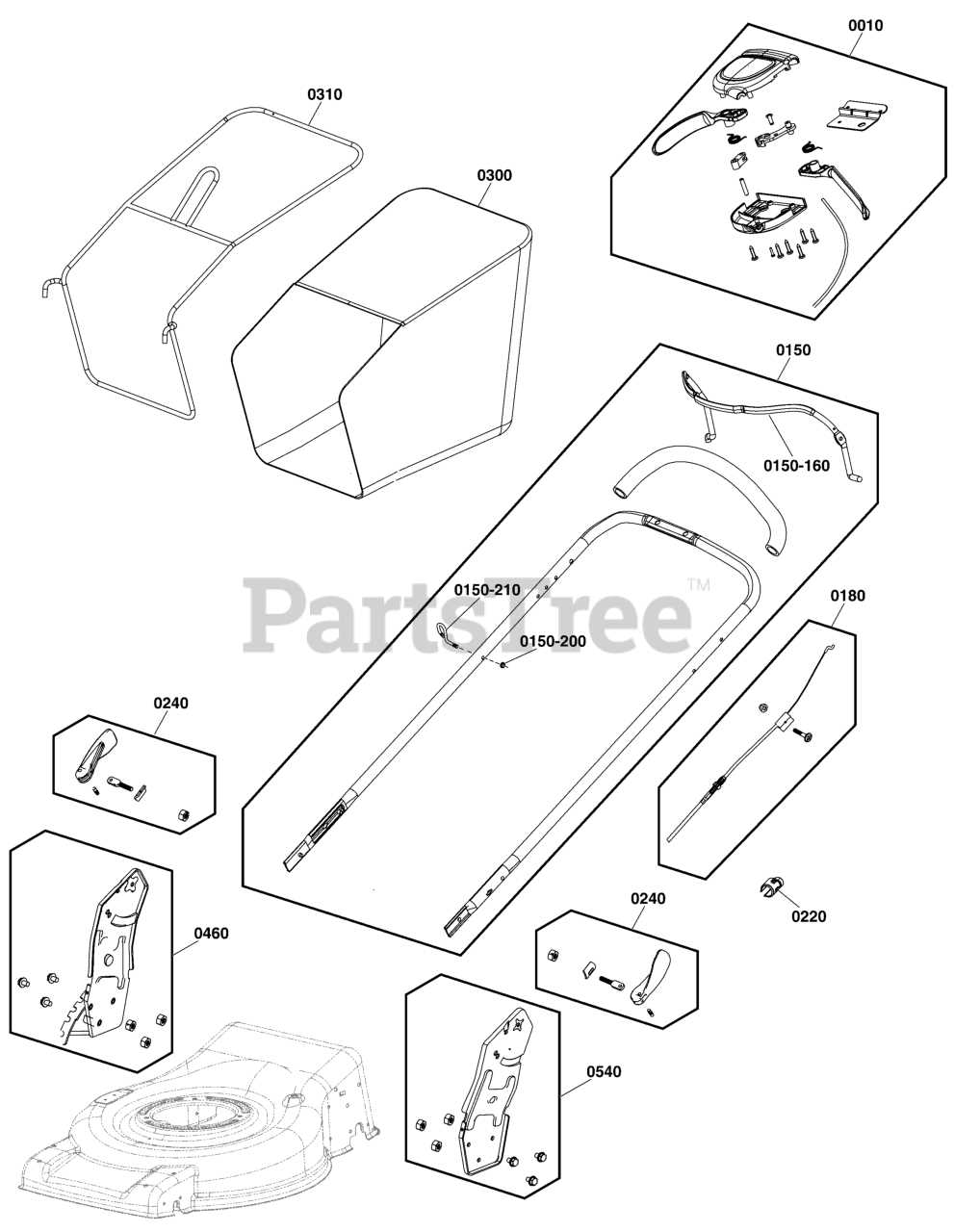

Handle Assembly and Control Functions

The handle assembly plays a crucial role in the operation and maneuverability of the equipment. It provides the necessary grip and support for the user, allowing for effective control over movement and various functions. Understanding the components and their interactions can enhance both the performance and ease of use.

Components of the Handle Assembly

The handle assembly consists of several key elements that work together to ensure smooth operation. These components include the main handle, control levers, and safety features that help prevent accidents during use.

| Component | Description |

|---|---|

| Main Handle | Provides a grip for maneuvering the equipment. |

| Control Levers | Regulate speed and other functions, allowing for customization. |

| Safety Features | Includes mechanisms to prevent unintended activation. |

Control Functions Overview

Control functions are integral to ensuring that the equipment operates effectively. The user can easily adjust speed settings and activate different modes through the control levers. Familiarity with these functions enhances the overall experience and allows for precise handling.

Tips for Regular Mower Maintenance

Keeping your grass cutting machine in prime condition is essential for optimal performance and longevity. Regular upkeep not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Here are some valuable practices to consider.

1. Clean the Deck: After each use, ensure that the underside of the cutting deck is free from clippings and debris. This prevents rust and maintains cutting efficiency.

2. Check the Blades: Inspect and sharpen the blades regularly. Dull blades can tear the grass rather than cut it, leading to a less healthy appearance.

3. Change the Oil: Just like any engine, regular oil changes are crucial. Follow the manufacturer’s recommendations for frequency and type of oil.

4. Replace Air Filters: Clean or replace the air filter periodically to ensure optimal airflow to the engine, which helps it run smoothly.

5. Inspect Cables and Belts: Regularly check for wear or damage to cables and belts. Address any issues early to avoid further complications.

6. Store Properly: When not in use, store your machine in a dry, sheltered area. This protects it from the elements and prolongs its lifespan.

Implementing these tips can significantly enhance the performance and durability of your grass cutting equipment, ensuring it remains an ultimate tool in your gardening arsenal.