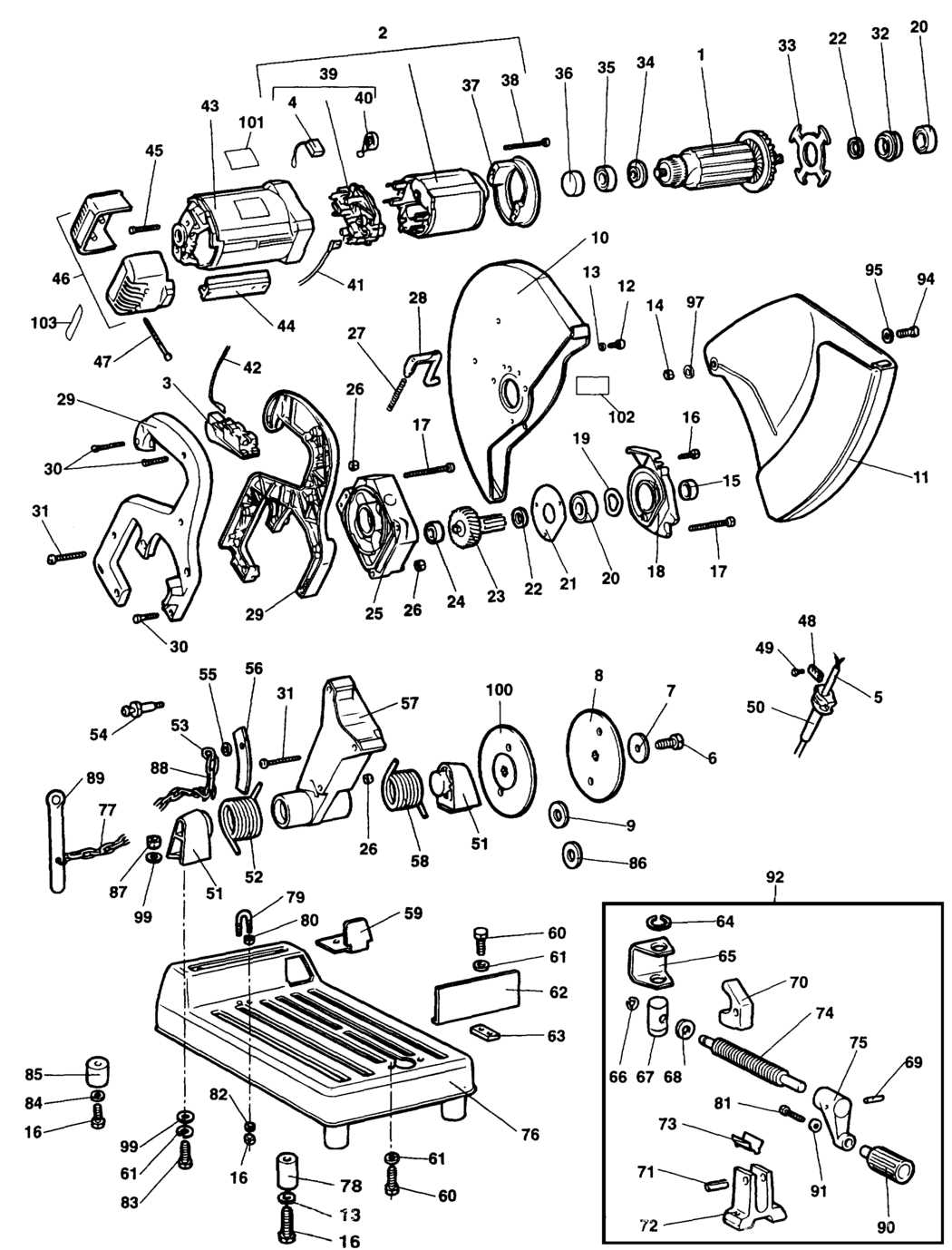

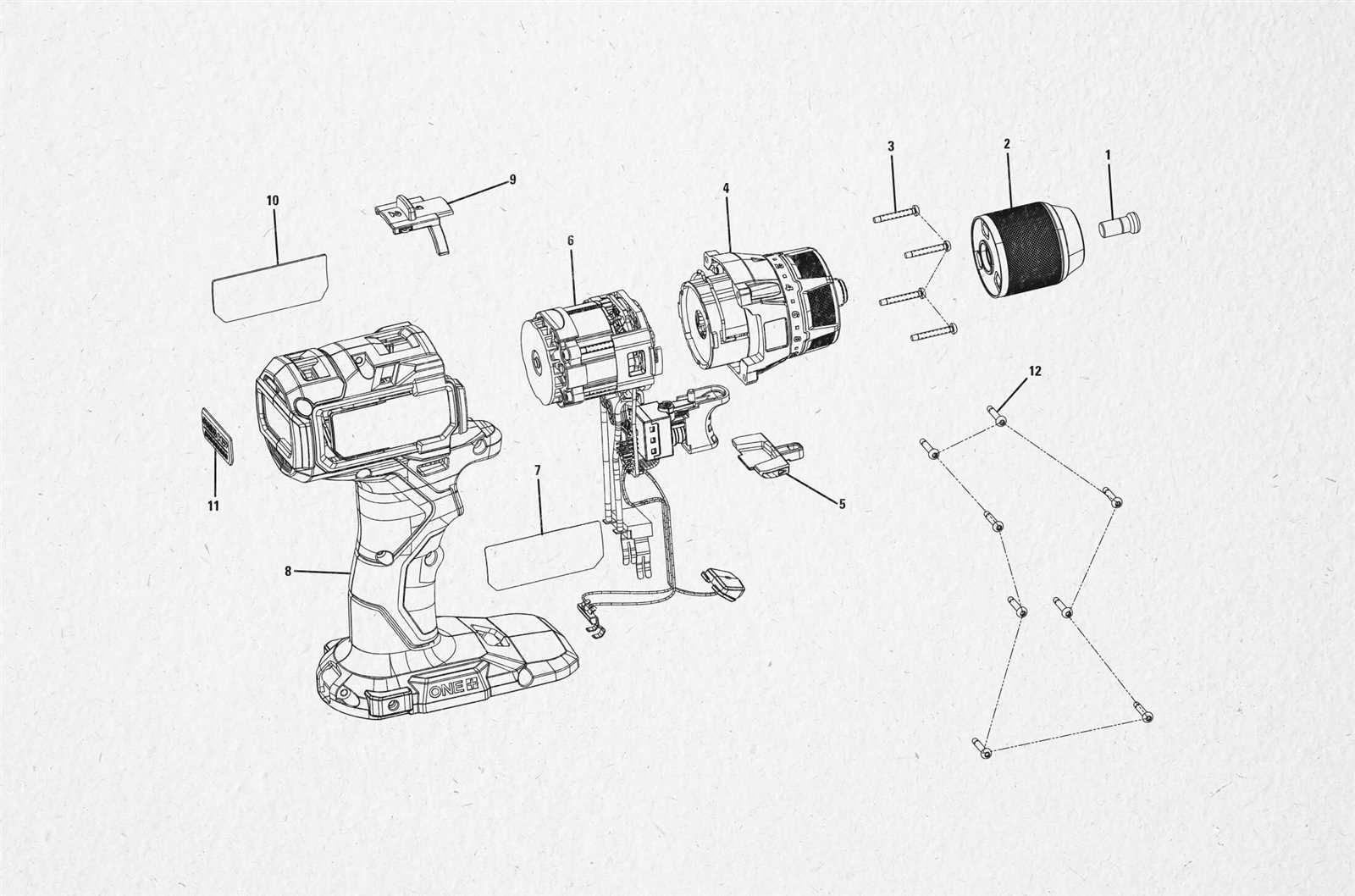

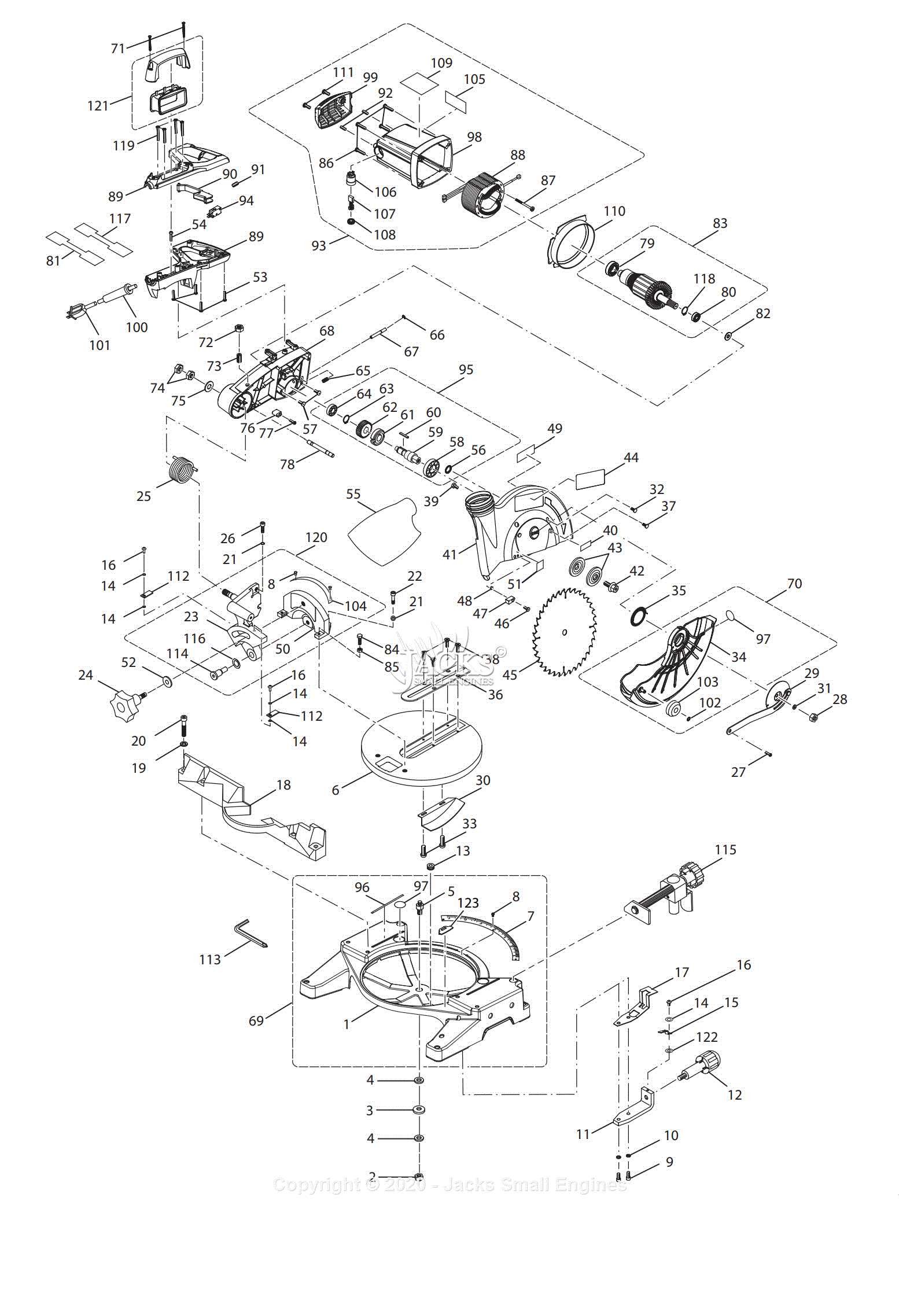

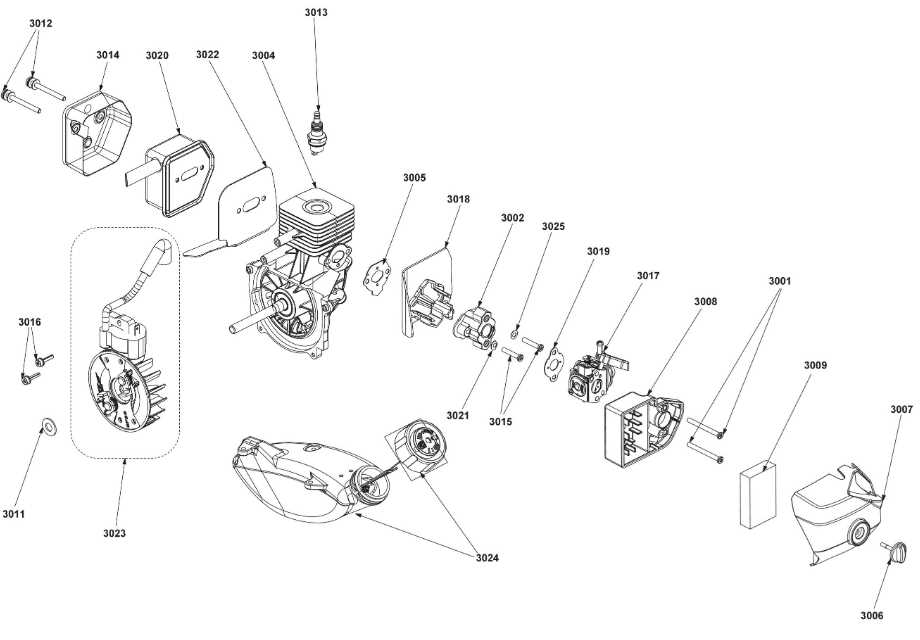

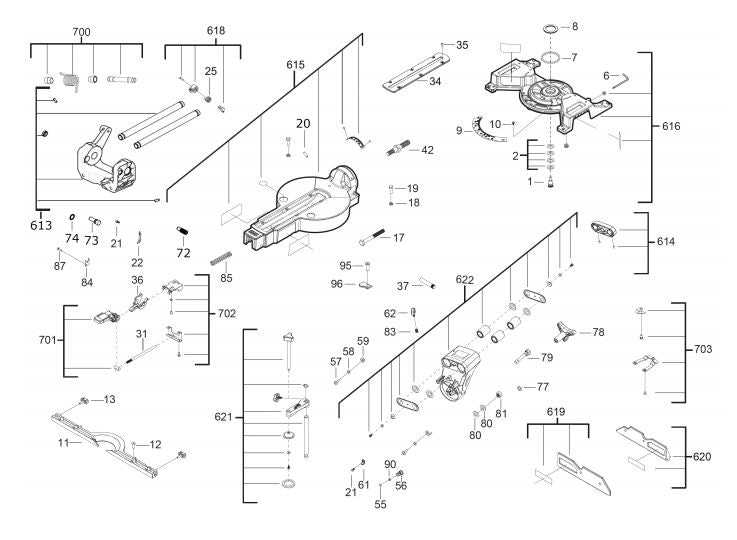

Every craftsman knows that the efficiency of their cutting equipment hinges on its individual elements. A thorough grasp of these components not only enhances operational effectiveness but also simplifies maintenance and repairs. By familiarizing yourself with each segment of your device, you can ensure optimal performance and longevity.

In this section, we will explore a comprehensive visual representation that illustrates the various constituents of your cutting instrument. This guide serves as a valuable resource, providing insights into how each piece interrelates, thereby enhancing your ability to troubleshoot and replace parts when necessary. Whether you are a novice or an experienced user, understanding the anatomy of your tool is crucial for any successful project.

As we delve deeper, we will discuss the significance of each part, emphasizing their roles in the overall functionality of the equipment. Recognizing the importance of these elements will empower you to make informed decisions, ensuring your device operates at peak performance for years to come.

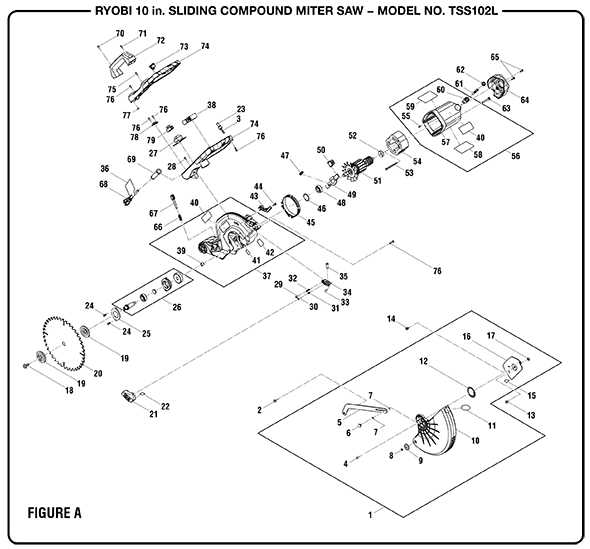

Understanding Ryobi Miter Saw Components

Grasping the various elements of a cutting tool is essential for optimal performance and maintenance. Each component plays a crucial role in ensuring accuracy and efficiency during operations. This section will delve into the fundamental parts that contribute to the functionality of these power tools.

Main Components

The primary sections of a cutting tool include the base, arm, and cutting head. Each part must be well-maintained to guarantee smooth operation and longevity. Below is a brief overview of these essential components:

| Component | Function |

|---|---|

| Base | Provides stability and support during cuts. |

| Arm | Holds the cutting head and allows for angular adjustments. |

| Cutting Head | Houses the blade and is responsible for the actual cutting action. |

Additional Features

Aside from the primary components, additional features enhance the tool’s versatility. These may include laser guides for precision, dust collection systems for cleanliness, and safety switches for user protection. Understanding these elements can significantly improve the cutting experience and ensure safer operations.

Importance of Parts Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. Visual representations of these elements facilitate the identification and organization of each part, ensuring that users can efficiently manage their tools. Such illustrations serve as valuable resources for both novices and seasoned professionals.

Benefits of Visual References

- Enhanced Clarity: Visual aids provide a clear view of each component, making it easier to locate specific items.

- Streamlined Repairs: Knowing the layout allows for quicker troubleshooting and assembly, reducing downtime.

- Improved Learning: Beginners can grasp the function of each element more effectively through visual guides.

Facilitating Efficient Maintenance

- Identification: Users can easily pinpoint worn or damaged components.

- Ordering Parts: Understanding the exact pieces needed simplifies the purchasing process.

- Reassembly: Visual references ensure that all elements are correctly aligned and secured during reassembly.

Common Issues with Miter Saw Parts

Power tools are essential for precision cutting, but they can encounter various challenges that affect their performance. Understanding these common issues can help users troubleshoot and maintain their equipment effectively, ensuring longevity and accuracy in their projects.

| Issue | Description | Possible Solution |

|---|---|---|

| Blade Misalignment | A misaligned blade can result in uneven cuts and safety hazards. | Regularly check alignment using a square and adjust as needed. |

| Worn-Out Blade | Blades that have lost their sharpness can produce rough edges and require more effort. | Replace the blade or sharpen it to maintain cutting efficiency. |

| Motor Overheating | Excessive use without breaks can lead to overheating, which may damage internal components. | Allow the tool to cool down periodically and ensure proper ventilation. |

| Dust Buildup | Accumulation of sawdust can hinder operation and visibility. | Clean the area regularly and use a vacuum attachment to minimize debris. |

| Loose Fasteners | Vibration can cause screws and bolts to loosen over time. | Inspect and tighten all fasteners periodically to ensure stability. |

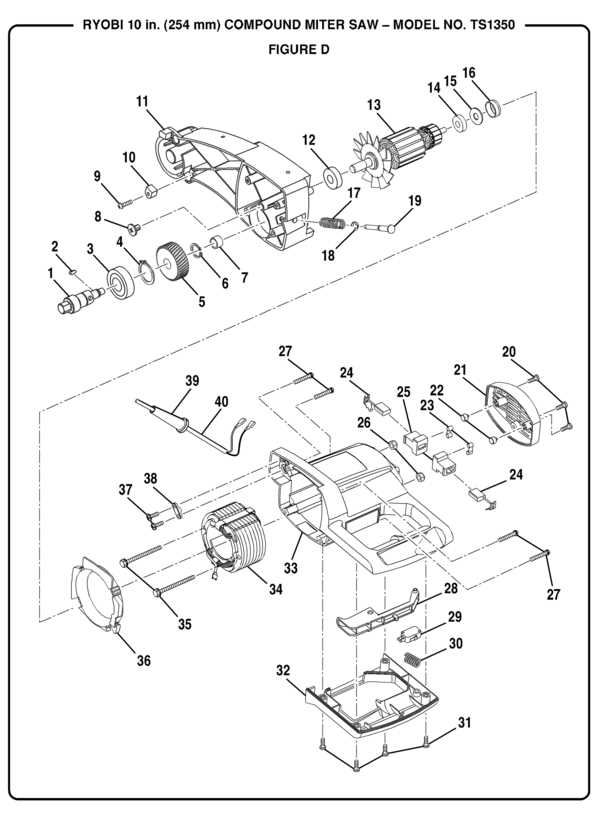

How to Identify Replacement Parts

When it comes to maintaining your equipment, understanding how to pinpoint the necessary components is essential for optimal performance. By following a systematic approach, you can ensure that you select the right items for your needs.

1. Refer to the User Manual: Always start with the user manual provided by the manufacturer. It often contains detailed information about the various components and their corresponding model numbers.

2. Model Number Identification: Locate the model number on your device, usually found on a label. This identifier is crucial for finding compatible replacements.

3. Online Resources: Utilize manufacturer websites or online forums dedicated to the equipment. These platforms often feature helpful diagrams and community advice that can assist you in identifying what you need.

4. Consult Retailers: When in doubt, visit local retailers or online shops that specialize in tools. Their staff can often help you discern which items are suitable replacements.

5. Visual Inspection: Conduct a thorough examination of your equipment. Take note of any visible damage or wear, as this can guide you in determining which elements require replacement.

By following these steps, you can effectively navigate the process of identifying and acquiring the right components for your equipment, ensuring it operates at its ultimate efficiency.

Maintenance Tips for Your Miter Saw

Regular upkeep of your cutting tool is essential for optimal performance and longevity. By following a few simple practices, you can ensure that your equipment remains in top condition, enhancing both precision and safety during use.

Routine Cleaning

Keeping your device clean is crucial for efficient operation. Dust and debris can affect performance and accuracy.

- Use a soft brush or compressed air to remove sawdust from the motor and housing.

- Wipe down surfaces with a damp cloth to prevent residue build-up.

- Check and clean the cutting area regularly to maintain clear visibility.

Regular Inspections

Frequent checks help identify potential issues before they escalate.

- Inspect the blade for signs of wear or damage; replace it if necessary.

- Check all moving parts for lubrication needs to prevent rust and ensure smooth operation.

- Examine electrical connections for fraying or damage to maintain safety.

Adhering to these maintenance tips will not only prolong the life of your cutting tool but also enhance the quality of your work.

Finding Genuine Ryobi Parts Online

When it comes to maintaining your tools, ensuring you have the right components is essential for optimal performance and longevity. Sourcing authentic replacements can be a challenge, but with the right approach, you can easily find what you need without hassle.

Here are some reliable methods to discover genuine components online:

| Method | Description |

|---|---|

| Official Website | Start by visiting the manufacturer’s official website. They often have a dedicated section for replacement components and accessories. |

| Authorized Retailers | Check with authorized sellers who specialize in tools. These retailers typically stock genuine items and can assist with specific inquiries. |

| Online Marketplaces | Platforms like Amazon or eBay may offer authentic items, but ensure you verify the seller’s reputation and read reviews before purchasing. |

| Community Forums | Join online communities or forums where enthusiasts gather. Members often share reliable sources for authentic components and helpful tips. |

By utilizing these strategies, you can confidently secure the necessary items to keep your equipment in peak condition.

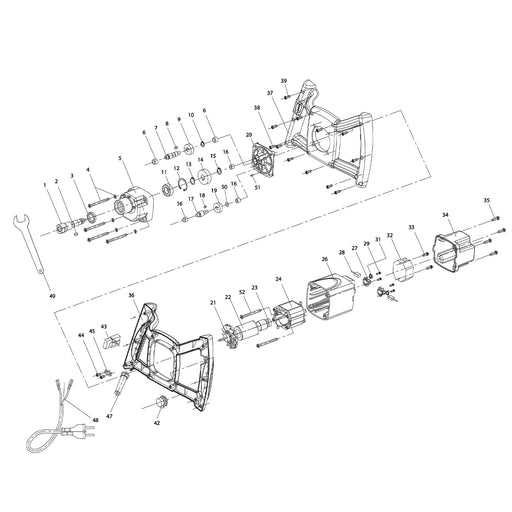

Assembly Instructions for Miter Saws

This section outlines essential guidelines for assembling cutting tools designed for precise angles. Proper construction ensures optimal performance and safety during usage.

Essential Tools Required

- Screwdriver set

- Wrench

- Allen keys

- Safety goggles

- Work gloves

Step-by-Step Assembly Process

- Begin by gathering all components and tools.

- Refer to the provided instructions for the sequence of assembly.

- Secure the base to a stable surface.

- Attach the arm mechanism carefully, ensuring all bolts are tightened.

- Install the cutting blade, confirming its orientation and secure fit.

- Double-check all connections before powering on the tool.

Following these steps will help you achieve a reliable and functional tool ready for various cutting tasks.

Upgrades and Accessories for Enhanced Performance

Optimizing the functionality of your cutting tool can significantly enhance your woodworking experience. By incorporating advanced components and attachments, you can achieve greater precision, efficiency, and versatility in your projects. This section explores some of the most effective enhancements available.

Essential Upgrades

Consider upgrading the blade for improved cutting accuracy and speed. High-quality blades reduce friction and enhance longevity, making them a worthwhile investment. Additionally, incorporating a laser guide can provide clear alignment, ensuring each cut is straight and true.

Useful Accessories

Accessories like extension tables and clamps can increase stability and support for larger materials. A dust collection system is also invaluable, as it maintains a clean workspace and improves visibility during use.

| Upgrade/Accessory | Benefits |

|---|---|

| High-Quality Blade | Improves cutting precision and lifespan |

| Laser Guide | Enhances alignment for accurate cuts |

| Extension Table | Provides additional support for larger pieces |

| Dust Collection System | Keeps workspace clean and clear |

Safety Considerations When Using Saws

Working with cutting tools can be rewarding but also presents certain hazards. Understanding and applying safety measures is essential to prevent accidents and injuries. Adopting a proactive approach ensures not only your safety but also the well-being of those around you.

- Personal Protective Equipment (PPE):

- Always wear safety glasses to protect your eyes from flying debris.

- Use ear protection to shield your hearing from loud noises.

- Wear appropriate gloves to enhance grip and prevent cuts.

- Consider dust masks to avoid inhaling harmful particles.

- Workspace Preparation:

- Keep your work area clean and free of clutter.

- Ensure proper lighting to clearly see your work.

- Maintain adequate ventilation, especially when cutting materials that generate dust.

- Tool Maintenance:

- Regularly inspect tools for any signs of wear or damage.

- Ensure blades are sharp and properly installed to reduce the risk of kickback.

- Follow the manufacturer’s guidelines for maintenance and repairs.

- Operational Practices:

- Read and understand the operating manual before use.

- Use the appropriate tool for the job to avoid misuse.

- Keep hands and other body parts away from the cutting area.

- Never bypass safety features or guards.

By adhering to these safety considerations, users can significantly reduce the risk of accidents and ensure a safer working environment. Always prioritize safety to enjoy a productive and worry-free experience.