In any aquatic management system, the efficiency of circulation is paramount. A comprehensive grasp of the intricate elements that contribute to optimal functionality can greatly enhance performance and longevity. This exploration aims to elucidate the various components involved in these systems, shedding light on their roles and interconnections.

By delving into the specifics, users can gain insights into how each piece interacts with the others, facilitating a seamless flow of water. Recognizing the importance of each component empowers operators to make informed decisions regarding maintenance and troubleshooting, ultimately ensuring a reliable and effective setup.

Moreover, visual representations of these intricate systems serve as invaluable tools for both novices and seasoned professionals. Understanding the layout and function of each element can simplify repairs and upgrades, promoting a more sustainable and efficient aquatic environment.

Understanding Jandy Pool Pumps

Comprehending the components and functionality of a water circulation system is essential for maintaining a clean and inviting recreational area. These systems are designed to ensure efficient water movement, filtration, and overall hygiene, which are vital for an enjoyable environment. A thorough understanding of the various elements involved can greatly enhance the effectiveness and longevity of the system.

The main components consist of a motor, an impeller, and a housing unit. Each part plays a critical role in achieving optimal performance. The motor is responsible for driving the entire mechanism, while the impeller facilitates water flow. The housing serves as a protective shell, ensuring that all elements work harmoniously together.

Regular maintenance and familiarity with the design can prevent common issues, allowing for timely repairs and replacements when necessary. Understanding how these elements interact can lead to improved efficiency and reduced energy consumption, ultimately benefiting both the environment and your finances.

In addition, knowing the specific configuration and layout can aid in troubleshooting problems. Whether dealing with leaks or unusual noises, being aware of how everything fits together can simplify the diagnosis process and save time in addressing issues.

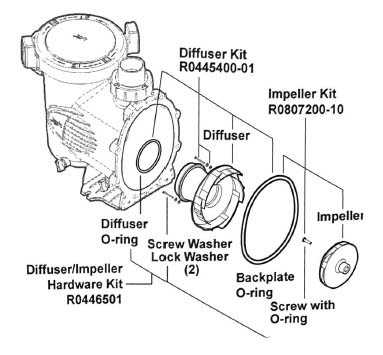

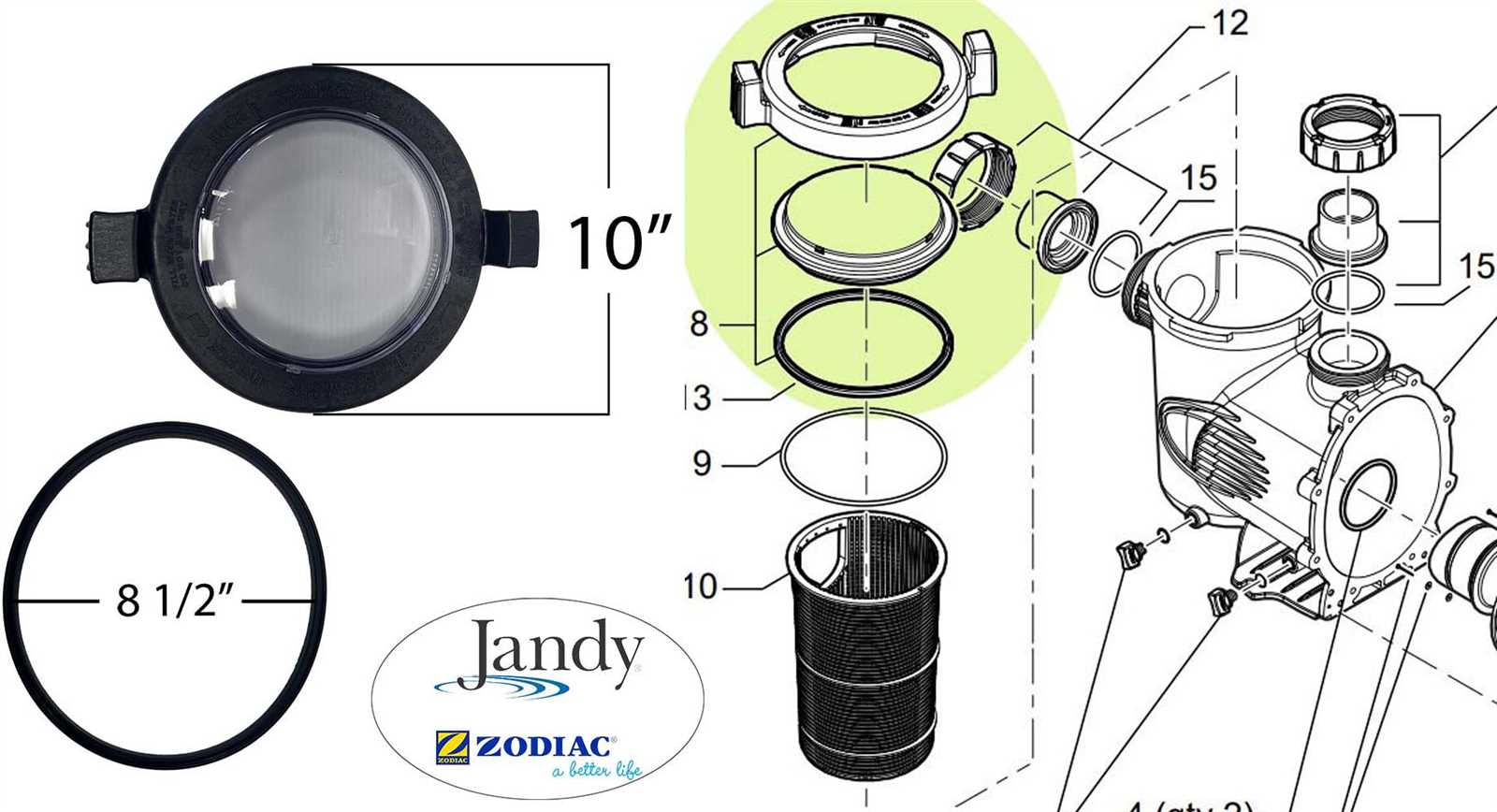

Key Components of Pool Pump Systems

Understanding the essential elements of water circulation systems is crucial for maintaining a clean and healthy environment. Each component plays a significant role in ensuring efficient operation and longevity. From the initial intake of water to the final distribution, every part contributes to the overall functionality.

1. Motor: The motor serves as the driving force behind the entire mechanism, converting electrical energy into mechanical energy to facilitate water movement. Its efficiency directly impacts the system’s performance and energy consumption.

2. Impeller: This component is responsible for creating the flow of water. Its design affects the velocity and volume of water being circulated, making it vital for achieving optimal results.

3. Strainer: Acting as a filter, the strainer prevents debris and larger particles from entering the system. Regular maintenance of this part is essential to avoid clogs and ensure smooth operation.

4. Volute: This housing directs the flow of water from the impeller to the discharge outlet. Its design influences the system’s efficiency and is crucial for maintaining proper pressure levels.

5. Seal: Preventing leaks, the seal is a critical element that safeguards the motor and other internal components from water damage. Regular inspection can prevent costly repairs.

6. Base: The sturdy foundation of the entire system, the base provides stability and support, ensuring that all components function correctly without unnecessary vibrations or movements.

Each of these key components works in harmony to ensure the seamless operation of water circulation systems, making understanding their functions essential for effective maintenance and repair.

How to Read Pump Parts Diagrams

Understanding the layout of components in a system is crucial for effective maintenance and troubleshooting. Familiarity with these visuals enables you to identify specific elements and their functions, leading to more efficient repairs and replacements. This section will guide you through the essential steps to interpret these schematics accurately.

Key Elements to Identify

- Labels: Look for text that names each component, as these provide immediate context.

- Symbols: Recognize standardized icons that represent various elements, which can differ by manufacturer.

- Connections: Pay attention to lines indicating how different parts interact or connect with one another.

Steps to Interpretation

- Familiarize Yourself: Spend time reviewing the layout to understand the overall configuration.

- Match Components: Cross-reference the labeled items with actual pieces in the system.

- Follow Flow Directions: Identify the flow paths to comprehend how the system operates.

- Consult Additional Resources: Use manuals or online guides for clarification on specific components.

Common Jandy Pump Models Overview

This section provides insights into various models of a well-known brand, focusing on their unique features and applications. Understanding the distinctions between these options can help users make informed decisions based on their specific needs and preferences.

Model Features

Each model in the lineup boasts its own set of characteristics. From energy efficiency to flow rate capabilities, these machines are designed to cater to different requirements. Some models prioritize quiet operation, making them ideal for residential areas, while others emphasize high performance for larger installations. Familiarizing oneself with these attributes can significantly enhance user experience.

Maintenance and Reliability

Regular upkeep is essential for optimal functionality. Models are generally engineered for ease of maintenance, with accessible components that facilitate routine checks and repairs. Users can expect durability, as many units come with warranties that underscore their reliability. Investing in a trusted model ensures longevity and peace of mind for any aquatic environment.

Importance of Regular Maintenance

Consistent upkeep is vital for ensuring optimal performance and longevity of any mechanical system. Without it, minor issues can escalate into significant problems, leading to costly repairs or replacements.

Regular checks can identify wear and tear early, allowing for timely interventions. This proactive approach not only enhances efficiency but also promotes safety for users.

Moreover, a well-maintained system can contribute to lower energy consumption, resulting in cost savings over time. Ultimately, dedicating time to routine care can yield significant benefits, ensuring that everything operates smoothly for years to come.

Troubleshooting Common Pump Issues

Dealing with mechanical failures can be frustrating, especially when essential components don’t function as expected. Identifying and resolving these issues quickly is crucial to maintain efficiency and extend the lifespan of the equipment. Below are some common problems and practical solutions to help you get back on track.

Common Problems

- Noisy Operation: Excessive noise can indicate wear and tear or foreign objects obstructing the mechanism.

- Inadequate Flow: A decrease in flow rate may result from clogs or blockages in the system.

- Leakage: Fluid leaks can stem from damaged seals or loose connections.

- Overheating: High temperatures may arise due to prolonged use or insufficient ventilation.

Quick Solutions

- Inspect and Clean: Regularly check for debris and clean components to ensure unobstructed operation.

- Check Connections: Tighten any loose fittings and replace worn seals to prevent leaks.

- Monitor for Overuse: Allow adequate rest periods to avoid overheating and ensure proper airflow.

- Seek Professional Help: If problems persist, consult an expert for comprehensive diagnostics and repairs.

Replacing Parts: A Step-by-Step Guide

When it comes to maintaining your equipment, understanding how to replace essential components can save both time and money. This guide will walk you through the necessary steps to ensure a smooth and efficient replacement process, enabling your system to function optimally once again.

Preparation

Before you begin, it’s crucial to gather the right tools and materials. Follow these steps to prepare:

- Identify the components that need replacement.

- Gather necessary tools, such as screwdrivers, wrenches, and pliers.

- Ensure you have the replacement parts ready for installation.

- Turn off all power sources connected to the system.

Replacement Process

Now that you’re prepared, follow these detailed steps for replacing the components:

- Remove any covers or barriers that obstruct access to the components.

- Carefully disconnect the old component, taking note of how it is attached.

- Install the new component, ensuring it is secured properly.

- Replace any covers or barriers that were removed.

- Restore power and check for functionality.

By following these guidelines, you can effectively replace components and maintain the efficiency of your equipment.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward task if you know where to look. Various resources are available to help you source the items you need, ensuring your system operates efficiently.

Online Retailers

- Specialty websites dedicated to equipment maintenance

- Major e-commerce platforms with extensive inventories

- Manufacturer’s official website for genuine components

Local Suppliers

- Home improvement stores often carry common items

- Dedicated repair shops can provide expert advice and stock

- Wholesale distributors may have bulk options available

Upgrading Your Pool Pump System

Enhancing your aquatic circulation system can significantly improve its efficiency and longevity. A modernized setup not only boosts performance but also contributes to energy savings and reduces maintenance costs. This section outlines essential considerations for optimizing your system.

When contemplating an upgrade, it’s vital to assess the current components and their compatibility with newer technologies. Evaluating your existing configuration will help identify potential areas for improvement, allowing for a seamless transition to a more efficient system.

| Component | Benefits of Upgrade |

|---|---|

| Motor | Increased efficiency, quieter operation |

| Control System | Enhanced automation, remote monitoring |

| Filtration Unit | Improved clarity, reduced chemical usage |

| Piping | Reduced friction loss, optimized flow |

Investing in superior components not only enhances operational capabilities but also extends the lifespan of the entire system. Make informed choices to enjoy a more effective and enjoyable aquatic environment.