In the world of machinery, comprehending the individual elements that make up a device is crucial for effective maintenance and repair. Each component plays a significant role in ensuring optimal performance and longevity. By gaining insights into these segments, users can enhance their operational efficiency and troubleshoot issues more effectively.

Every intricate system consists of various units, each interlinked to achieve the ultimate functionality. Understanding how these pieces interact can lead to more informed decisions during repairs or upgrades. This knowledge not only saves time but also reduces the risk of errors in handling the equipment.

In this section, we will explore the arrangement and relationships of the various elements, providing a clearer picture of how to navigate the complexities of your device. With a closer examination, users can delve into the specifics, ensuring they are well-equipped to manage their machinery with confidence.

Understanding Hrr2166vka Components

Grasping the intricacies of each individual element within a mechanical system is essential for optimal functionality and maintenance. This knowledge not only enhances performance but also aids in troubleshooting and repairs. Each component plays a specific role, contributing to the overall efficiency and reliability of the entire assembly.

To better comprehend the various elements, it is helpful to categorize them based on their functions and interactions. Below is a summary table that outlines the primary categories of these elements, along with their respective purposes.

| Component Category | Function |

|---|---|

| Power Unit | Supplies energy for operation |

| Transmission System | Transfers power to various parts |

| Control Mechanism | Regulates operation and efficiency |

| Safety Features | Ensures safe operation and prevents failures |

| Structural Elements | Provides support and stability |

Understanding these categories allows for a clearer insight into the entire mechanism’s functionality, making it easier to identify issues and carry out maintenance effectively. Each element is vital, and a comprehensive knowledge of their roles is crucial for any user or technician.

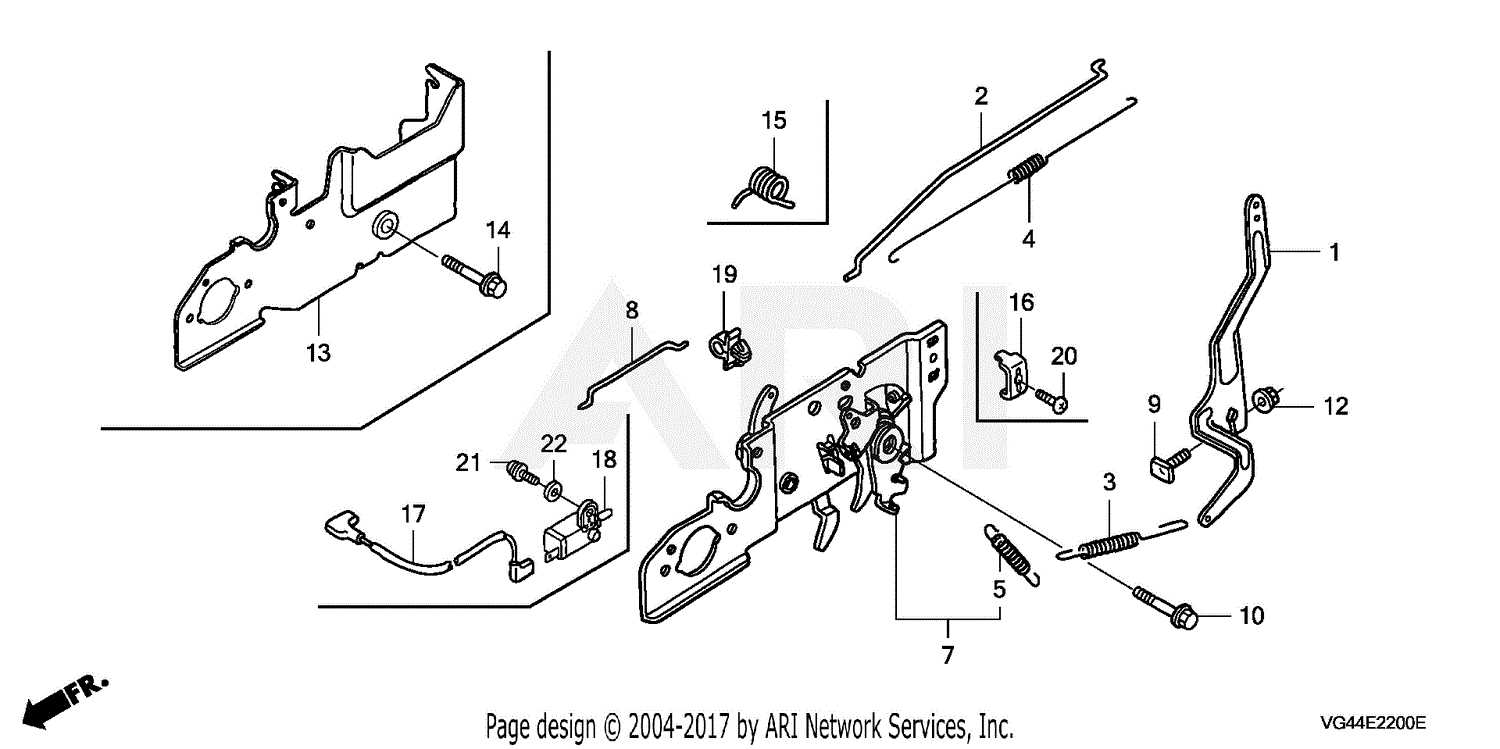

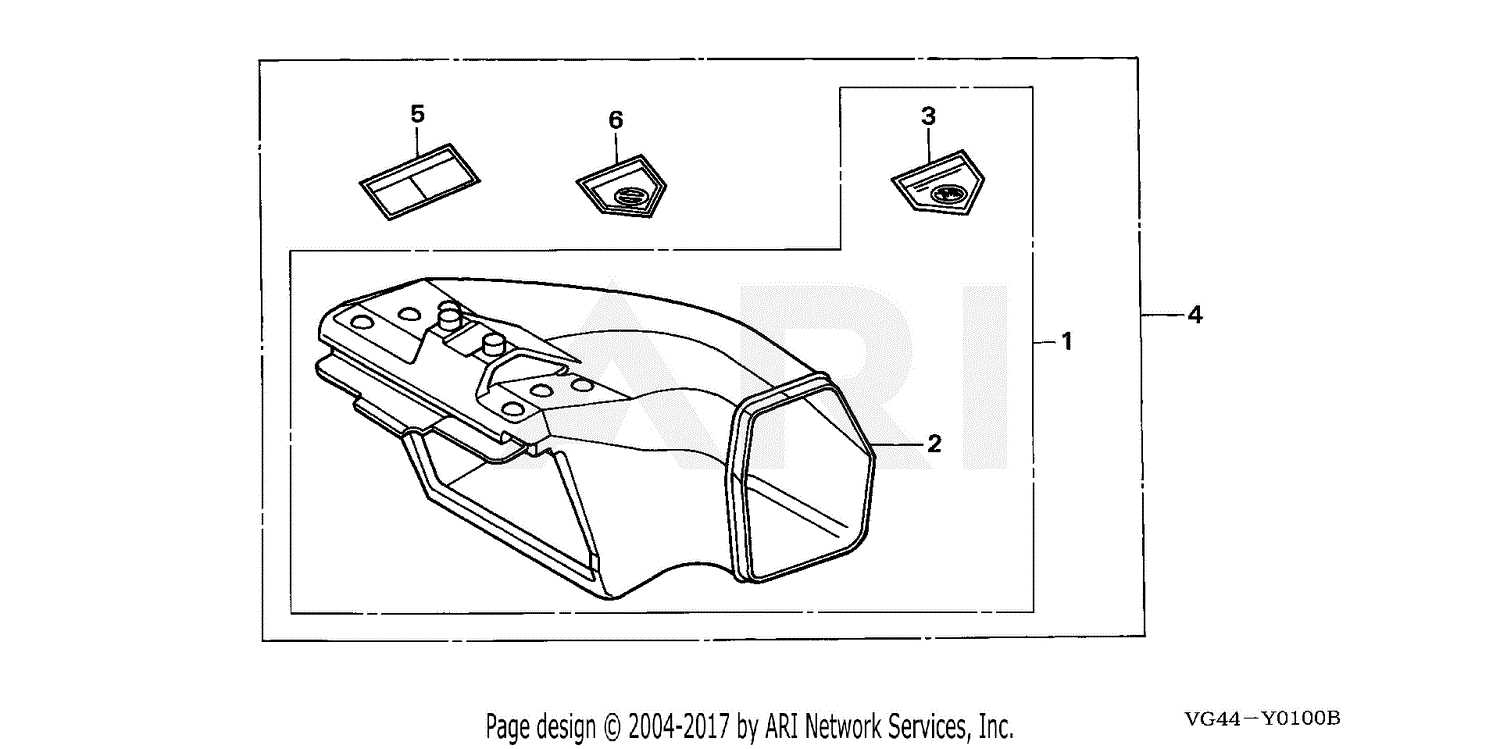

Importance of Parts Diagrams

Understanding the intricacies of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, offering insights into the components and their interrelations. These illustrations enable technicians to identify parts quickly, streamline repairs, and enhance overall efficiency.

Moreover, accurate visual aids foster better communication among team members, ensuring everyone is on the same page regarding assembly and disassembly processes. They also serve as valuable references for troubleshooting, allowing for swift identification of potential issues and solutions.

In addition, these representations play a pivotal role in training new personnel. By providing a clear overview of the structure, newcomers can grasp complex systems more easily, leading to a smoother onboarding experience. Overall, the availability of detailed visuals significantly contributes to the longevity and optimal performance of equipment.

Identifying Key Components in Hrr2166vka

Understanding the crucial elements of any mechanical system is essential for effective maintenance and operation. By recognizing these vital parts, users can enhance performance and troubleshoot issues more efficiently. Each component plays a significant role, contributing to the overall functionality and reliability of the unit.

Major Elements

Key elements include the engine, transmission, and electrical systems. Each of these parts works in harmony to ensure smooth operation, with specific functions that support overall performance.

Supportive Accessories

In addition to primary components, various supportive accessories, such as filters, belts, and sensors, are also essential. These elements contribute to the optimal functioning of the entire system, providing critical support and enhancing durability.

Common Issues with Hrr2166vka Parts

When dealing with various components of a specific model, users often encounter a range of challenges that can affect performance and longevity. Understanding these common problems can help in diagnosing issues early and ensuring smoother operation. Below are some frequent concerns that may arise with these components.

| Issue | Description | Possible Solutions |

|---|---|---|

| Wear and Tear | Over time, certain elements may degrade due to regular use, leading to decreased efficiency. | Regular maintenance and timely replacement of worn parts can help mitigate this. |

| Corrosion | Exposure to moisture and harsh conditions can cause rust and deterioration. | Using protective coatings and storing in dry conditions can minimize damage. |

| Misalignment | Components may become misaligned, leading to operational issues and increased wear. | Frequent checks and adjustments during maintenance can prevent this issue. |

| Blockages | Debris and foreign objects can obstruct function, impacting overall performance. | Regular cleaning and inspections are essential to avoid blockages. |

| Leakage | Seal failures can lead to fluid leaks, resulting in decreased performance and potential damage. | Inspecting seals and replacing them when necessary can help maintain integrity. |

How to Read a Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair tasks. These illustrations provide a clear overview of the various elements involved, allowing users to identify and locate each item with ease.

1. Familiarize Yourself with Symbols: Each element in the illustration is often represented by specific symbols or shapes. Take time to learn what these symbols signify, as they can vary between different models or manufacturers.

2. Refer to the Legend: Most illustrations include a legend or key that explains the symbols used. This is a crucial resource for deciphering the meanings behind the visuals, ensuring accurate interpretation.

3. Follow the Flow: Pay attention to the layout and flow of the components. Many illustrations are designed to represent the assembly or operational sequence, so understanding this order can enhance your comprehension of the system.

4. Cross-Reference with Manuals: Using the visual alongside user manuals or technical documentation can provide additional context. This combination of resources helps clarify any uncertainties and reinforces your understanding.

5. Practice Makes Perfect: The more you engage with these visual aids, the more proficient you’ll become at reading and interpreting them. Over time, this skill will enhance your overall capability in troubleshooting and repairs.

Maintenance Tips for Hrr2166vka

Regular upkeep is essential to ensure optimal performance and longevity of your lawn equipment. By following a structured maintenance routine, you can prevent common issues and enhance the efficiency of your machine. Here are some practical suggestions to keep your device in top shape.

Routine Checks

Conduct frequent inspections of the machine to identify any wear and tear. Focus on the cutting mechanism and the motor. Ensure that all components are secure and free from debris. Cleaning is crucial; remove grass clippings and dirt after each use to avoid build-up that can affect performance.

Lubrication and Adjustments

Regularly lubricate moving parts to minimize friction and prevent rust. Use high-quality oil recommended by the manufacturer. Additionally, check and adjust the tension of the belts and cables periodically. Proper tension is vital for smooth operation and prevents potential damage.

Where to Find Replacement Parts

Finding the right components for your equipment can often feel overwhelming, but there are several reliable sources to consider. Whether you’re looking for OEM items or compatible alternatives, understanding where to search can save you time and money.

Online Retailers

Numerous online platforms specialize in providing various components. Here are some popular options:

- Manufacturer’s Official Website: This is often the best place to start for original parts.

- Third-Party Marketplaces: Websites like Amazon and eBay offer a range of options, including used and aftermarket items.

- Specialized Retailers: Certain websites focus specifically on equipment parts, offering a broad selection.

Local Stores and Workshops

In addition to online options, local resources can also be beneficial. Consider the following:

- Home Improvement Stores: Many carry common components and accessories.

- Specialty Shops: Stores that focus on specific types of equipment may have what you need.

- Repair Shops: Local repair services can often order specific items or might have spare ones available.

Assembly Process of Hrr2166vka

The assembly process involves a systematic approach to bring together various components, ensuring functionality and efficiency. This structured method allows for the creation of a cohesive unit through careful integration of elements.

- Preparation of Components

- Inspect all elements for quality assurance.

- Organize tools and workspace for optimal workflow.

- Begin with the main structure.

- Attach secondary components as per guidelines.

- Incorporate moving parts to enhance functionality.

- Ensure alignment and proper fit for smooth operation.

- Test all features for operational efficiency.

- Make necessary adjustments to achieve optimal performance.

This thorough approach ensures that the end product is reliable and meets quality standards, ultimately leading to user satisfaction.

Upgrading Hrr2166vka Components

Enhancing the functionality and efficiency of your equipment can lead to improved performance and longevity. This process often involves replacing or upgrading certain elements to ensure optimal operation. Understanding the available options is crucial for making informed decisions that align with your specific needs.

Benefits of Upgrading

- Improved efficiency and power output.

- Enhanced durability and lifespan of the machinery.

- Better compatibility with modern technologies.

- Increased overall reliability and performance.

Key Components to Consider

- Engine: Upgrading the motor can provide more power and efficiency.

- Blades: Choosing high-quality blades can significantly improve cutting performance.

- Air Filters: Enhanced filtration systems can lead to better airflow and engine performance.

- Wheels: Consider upgrading to more durable wheels for improved maneuverability.

By strategically upgrading these components, you can maximize the performance and functionality of your equipment, ensuring it meets your expectations and requirements for years to come.