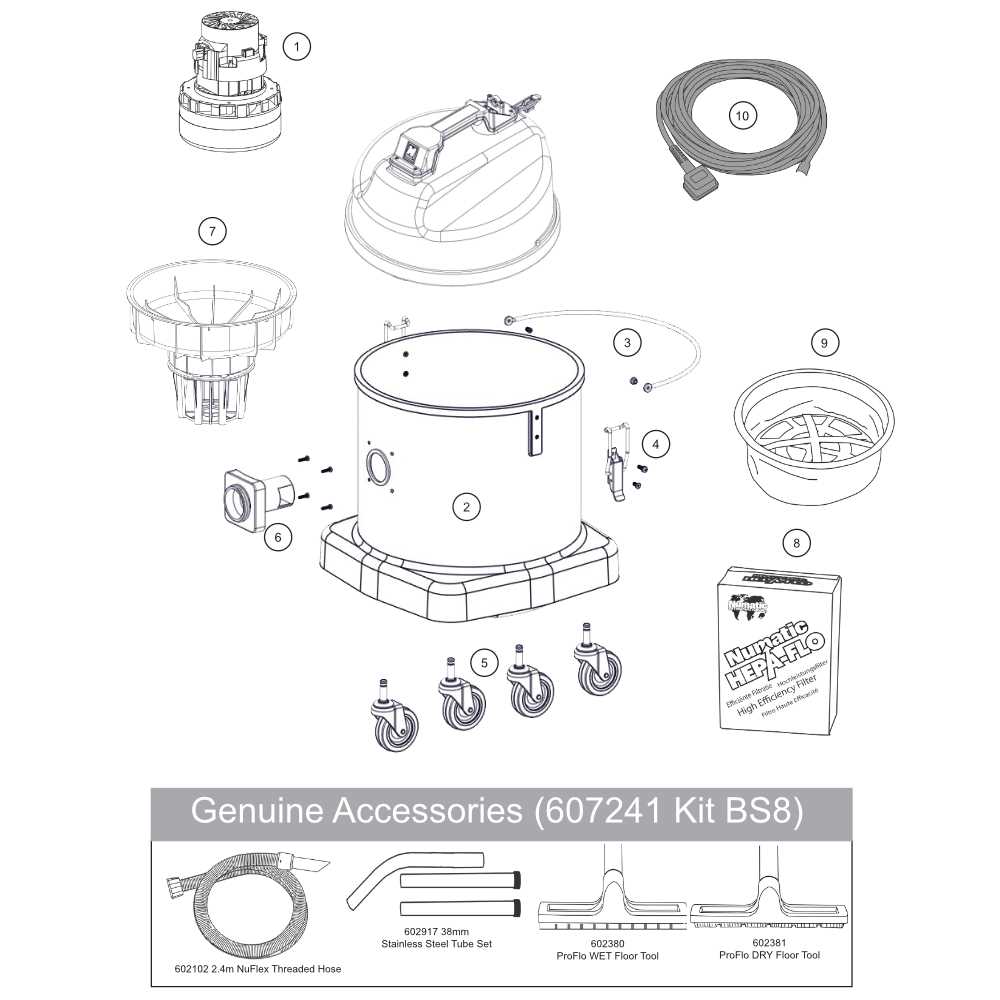

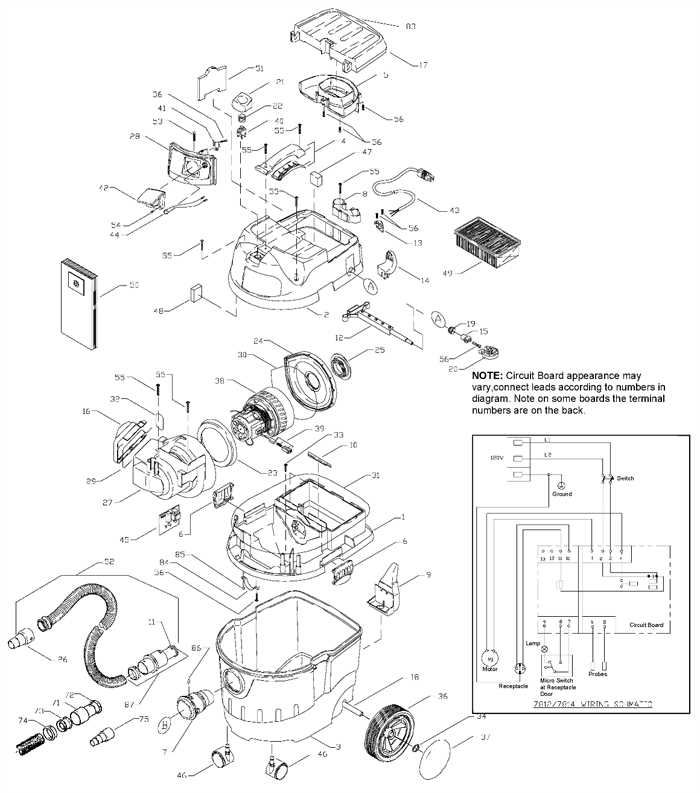

When it comes to maintaining and repairing your cleaning apparatus, having a clear overview of its individual elements is essential. A well-organized visual representation can significantly enhance your ability to troubleshoot and replace any malfunctioning pieces. Whether you’re dealing with an issue or simply looking to perform routine maintenance, knowing what each component does is invaluable.

The intricacies of your vacuum cleaner can often be daunting. Each part plays a crucial role in the overall functionality, and understanding their arrangement will empower you to tackle repairs with confidence. By familiarizing yourself with the layout, you can easily identify which segment needs attention, ensuring a more efficient cleaning experience.

Furthermore, a comprehensive guide can aid in sourcing replacement items, allowing you to keep your equipment in optimal condition. Whether you are a seasoned DIY enthusiast or a beginner, this resource will serve as a helpful companion in navigating the complex world of vacuum maintenance.

Understanding Shop-Vac Functionality

A vacuum system designed for both wet and dry cleaning offers versatile solutions for a variety of tasks. These devices are engineered to efficiently manage different types of debris, making them essential tools in workshops, garages, and construction sites. By comprehending their operational components, users can optimize performance and extend the lifespan of their equipment.

Key Components

The primary elements of these cleaning machines include the motor, filtration system, and collection tank. Each part plays a crucial role in ensuring effective suction and debris management. Understanding how these components interact helps in troubleshooting and maintenance.

| Component | Function |

|---|---|

| Motor | Powers the suction mechanism, generating airflow. |

| Filtration System | Catches particles to prevent them from being released back into the air. |

| Collection Tank | Holds the collected debris, allowing for easy disposal. |

Maintenance Tips

Regular upkeep of the vacuum system ensures optimal performance. This includes checking filters, cleaning the collection tank, and inspecting the motor for wear. By adhering to these practices, users can maintain the efficiency and effectiveness of their cleaning device over time.

Key Components of a Shop-Vac

Understanding the fundamental elements of a wet/dry vacuum cleaner is essential for effective use and maintenance. Each component plays a crucial role in the overall functionality, ensuring efficient suction and debris collection.

The motor serves as the powerhouse, generating the necessary suction to draw in materials. Coupled with the filter, it captures particles, preventing them from re-entering the air. The collection tank is where all debris accumulates, designed for easy emptying and cleaning.

Hoses and attachments are vital for versatility, allowing users to access tight spaces and handle various types of messes. Finally, the wheels and handles facilitate mobility, making it easier to transport the unit across different surfaces.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. This guide will help you navigate these illustrations, enabling you to identify and locate the necessary elements efficiently.

Follow these key steps to interpret the visual layout:

- Familiarize Yourself with the Symbols: Each illustration uses specific icons and notations. Recognizing these will help you understand what each part represents.

- Identify the Layout: Look for the overall structure. Components are usually organized logically, often from top to bottom or left to right.

- Refer to the Legend: Many visuals include a legend that explains the symbols used. This is crucial for accurate identification.

- Note the Numbers: Components are often labeled with numbers that correspond to a list or index. Use this to cross-reference details.

- Check for Variants: Some representations may include variations for different models. Ensure you are looking at the correct version for your needs.

By following these guidelines, you can effectively interpret a component layout and ensure you have the right information for your projects.

Common Shop-Vac Issues Explained

When utilizing powerful suction devices, users often encounter various challenges that can hinder performance. Understanding these common problems can lead to effective solutions, ensuring optimal functionality and longevity of the equipment.

Frequent Problems and Their Causes

| Issue | Possible Causes | Solutions |

|---|---|---|

| Poor suction | Clogged hose or filter | Inspect and clear any obstructions; replace filter if necessary. |

| Strange noises | Loose components or debris | Tighten loose parts; check for and remove foreign objects. |

| Overheating | Blocked airflow or dirty motor | Ensure proper ventilation; clean the motor area and filters. |

| Power issues | Faulty outlet or damaged cord | Test with a different outlet; replace the power cord if frayed. |

Preventive Maintenance Tips

Regular maintenance can significantly reduce the likelihood of encountering issues. Cleaning filters, checking hoses for blockages, and inspecting electrical connections will promote smooth operation and extend the lifespan of your device.

Replacing Worn Out Parts

Maintaining the efficiency of your cleaning equipment is crucial for its longevity and optimal performance. Over time, certain components may wear out, leading to decreased effectiveness and potential damage. Regularly assessing and replacing these aging elements can ensure your device continues to function smoothly.

Identifying Worn Components

Before you can replace any worn components, it’s essential to identify which parts are causing issues. Look for signs of wear such as cracks, tears, or decreased suction power. Routine inspections can help pinpoint problematic areas, allowing you to address them promptly and avoid further complications.

Steps for Replacement

Once you’ve identified the components that need replacing, follow these steps:

- Gather necessary tools: Ensure you have the right tools at hand to facilitate the replacement process.

- Refer to the user manual: Consult the manual for specific instructions related to your model.

- Carefully remove the old component: Take your time to avoid damaging surrounding parts.

- Install the new component: Ensure it fits securely and functions correctly.

By taking these steps, you can restore your equipment’s performance and extend its lifespan significantly.

Essential Tools for Repairs

Having the right equipment at your disposal can make all the difference when it comes to tackling repairs effectively. Whether you’re dealing with minor fixes or more extensive maintenance tasks, a well-equipped toolkit ensures that you can address issues promptly and efficiently. Below are some of the most important instruments you’ll want to have on hand for various repair activities.

Basic Tools Every DIYer Needs

To start, there are fundamental tools that serve as the backbone of any repair project. These items are versatile and applicable in numerous scenarios, making them invaluable for anyone looking to maintain their equipment or complete home repairs.

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for driving screws of various sizes and types. |

| Wrench Set | Ideal for loosening or tightening nuts and bolts. |

| Pliers | Great for gripping, twisting, or cutting wires and other materials. |

| Utility Knife | Perfect for cutting through packaging, materials, and more. |

| Measuring Tape | Essential for accurate measurements in any repair task. |

Specialized Tools for Specific Tasks

In addition to the basic tools, there are specialized instruments designed for particular repair needs. These tools enhance your ability to perform more complex tasks with precision, making them worthy investments for serious DIY enthusiasts.

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures that bolts are tightened to the correct specifications. |

| Heat Gun | Used for tasks like stripping paint or softening adhesives. |

| Multimeter | Measures electrical properties and helps diagnose issues. |

| Pipe Wrench | Designed for gripping and turning pipes. |

| Drill | Essential for making holes and driving fasteners. |

Upgrading Your Shop-Vac Performance

Enhancing the efficiency of your cleaning tool can significantly improve its functionality and overall effectiveness. By exploring various upgrades, you can achieve optimal performance that meets your specific needs. Whether it’s increasing suction power or extending usability, the right enhancements can transform your cleaning experience.

| Upgrade Type | Description |

|---|---|

| Filter System | Investing in a high-efficiency filter can capture smaller particles, ensuring cleaner air and improved suction. |

| Hoses | Replacing old hoses with larger diameter options can reduce clogging and increase airflow, enhancing overall performance. |

| Attachment Kits | Utilizing specialized attachments can make it easier to reach tight spaces, providing a thorough clean across various surfaces. |

| Power Boosters | Adding a power booster can elevate suction capability, allowing for more efficient debris pickup. |

Preventive Maintenance Tips

Regular upkeep is essential to ensure optimal performance and longevity of your cleaning equipment. Implementing a routine maintenance schedule can help you avoid unexpected breakdowns and costly repairs, ultimately enhancing efficiency and reliability.

Regular Inspections

Perform frequent checks to identify any wear or damage. Look for clogs, leaks, or signs of deterioration in hoses and connections. Early detection can save time and resources in the long run.

Cleaning and Lubrication

Keep all components clean and free of debris. Use appropriate lubricants on moving parts to reduce friction and prevent wear. A clean and well-lubricated unit operates more effectively and has a longer lifespan.