The intricate design of engines often involves a multitude of components working in harmony to ensure optimal performance. Each element, from the smallest fasteners to the major assemblies, plays a crucial role in the overall functionality. Grasping the relationship between these parts is essential for effective maintenance and repair.

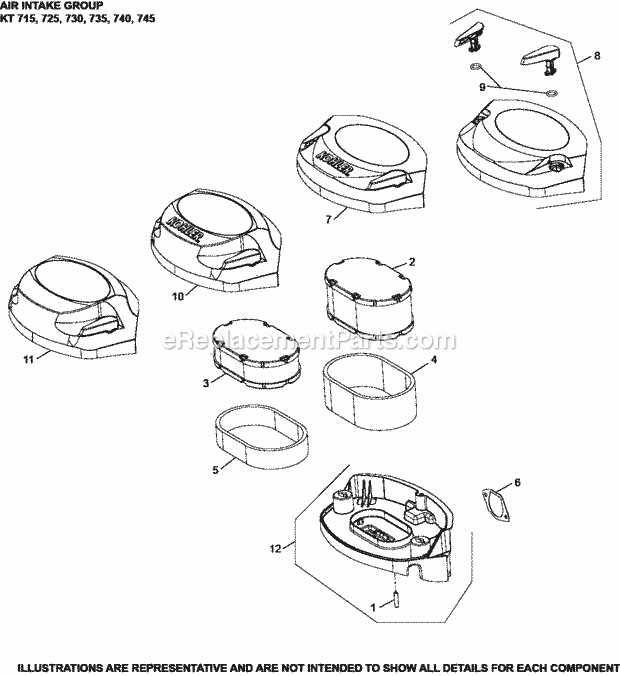

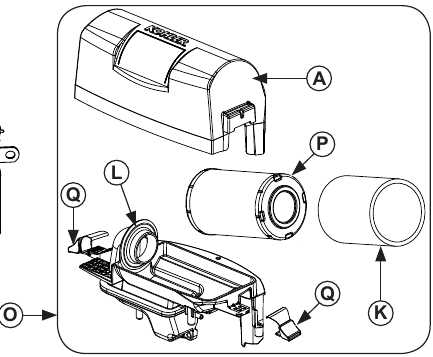

Visual representations of engine layouts provide valuable insights into how various components interact. These illustrations not only aid in identifying each part but also serve as a guide for troubleshooting and replacement. A well-organized schematic can significantly simplify the repair process, making it accessible even for those less experienced in engine mechanics.

In this section, we will explore the key features of these visual aids, highlighting their importance in the realm of engine maintenance. Understanding these diagrams empowers users to tackle repairs with confidence, ensuring that every aspect of the engine is accounted for and functioning efficiently.

Understanding the Kohler 7000 Series

This section explores the intricacies of a specific line of high-performance engines, focusing on their design, functionality, and maintenance. The aim is to provide a comprehensive understanding of the components that contribute to their efficiency and durability.

Key features include:

- Innovative engineering techniques

- Advanced fuel management systems

- Robust construction materials

To maximize the performance of these engines, consider the following maintenance tips:

- Regular oil changes to ensure optimal lubrication.

- Inspect air filters frequently to maintain airflow.

- Check spark plugs for wear and replace as needed.

Understanding these aspects will ultimately enhance the longevity and reliability of the equipment powered by these engines.

Overview of Kohler 7000 Components

This section provides a comprehensive examination of the various elements that constitute a specific engine model, highlighting their roles and interconnections. Understanding these components is essential for maintenance and performance optimization, ensuring efficient operation in various applications.

Key Elements

The main parts include the power unit, fuel system, and ignition assembly. Each element plays a vital role in the overall functionality, contributing to effective energy production and operational reliability.

Maintenance and Performance

Regular inspection of these components can lead to enhanced longevity and performance. Identifying wear or damage in the key elements helps in addressing issues before they escalate, ultimately ensuring peak operational efficiency.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the functionality and assembly of complex systems. They serve as essential tools for both technicians and enthusiasts, enabling efficient troubleshooting and maintenance.

Facilitating Maintenance

Having a clear illustration of components allows users to quickly identify and locate parts that require attention. This can significantly reduce downtime and enhance operational efficiency.

Streamlining Repairs

When performing repairs, accurate visuals aid in ensuring that each piece is correctly fitted and aligned. This not only improves the overall performance but also prolongs the lifespan of the equipment.

Common Issues with Kohler 7000 Parts

When dealing with components from a well-known engine brand, users may encounter a variety of challenges that can impact performance and reliability. Understanding these common problems is essential for maintenance and troubleshooting.

Wear and Tear: Over time, certain elements may experience significant deterioration due to frequent use. This can lead to reduced efficiency and, in some cases, complete failure. Regular inspection is crucial to identify signs of wear early.

Fuel System Problems: Inadequate fuel delivery can cause starting difficulties or erratic performance. Blockages or malfunctions in the fuel filter or pump are often culprits that need attention.

Electrical Issues: Electrical components may fail or malfunction, leading to starting problems or irregular operation. Corroded connections and worn-out wiring are common concerns that should be monitored.

Overheating: Excessive heat can result from poor cooling system performance, often due to debris blockage or coolant leaks. Regular checks can prevent serious damage.

Incorrect Maintenance: Neglecting routine maintenance tasks, such as oil changes and filter replacements, can lead to various operational issues. Adhering to the manufacturer’s guidelines is key to ensuring longevity and performance.

How to Read a Parts Diagram

Understanding an illustration of components is essential for effective maintenance and repair tasks. Such visuals provide a clear representation of individual elements and their relationships within a system, allowing users to identify and locate specific items quickly.

Begin by familiarizing yourself with the layout. Typically, these illustrations are organized to showcase the components in a logical order, often mirroring their arrangement in the actual machinery. Look for a legend or key that explains the symbols used, as this will guide you in interpreting the various parts correctly.

Next, pay attention to the numbering or labeling system. Each item is usually assigned a unique identifier, which corresponds to a list detailing specifications, quantities, or replacement options. This cross-referencing is vital for ensuring you obtain the correct items for any repairs or upgrades.

Visual cues play a significant role in understanding how each part interacts with others. Observe the connecting lines or arrows that indicate relationships, movements, or assemblies. This can provide insight into how to disassemble or reassemble components effectively.

Lastly, don’t hesitate to consult additional resources or manuals that might offer more detailed explanations or troubleshooting tips. By combining the visual representation with supplementary information, you’ll enhance your comprehension and confidence in managing any repairs.

Identifying Essential Spare Parts

Understanding the critical components of machinery is vital for effective maintenance and smooth operation. Recognizing which elements require regular attention and replacement can significantly enhance performance and extend the lifespan of the equipment. This section will guide you through the identification of key replacement components that are crucial for maintaining optimal functionality.

Key Components to Consider

- Fuel System Elements

- Electrical Components

- Air Intake Parts

- Cooling System Components

- Lubrication Elements

Each category plays a specific role in the overall efficiency and reliability of the equipment. Regular inspection and timely replacement of these items can prevent unexpected breakdowns and ensure continuous operation.

Steps to Identify Essential Components

- Review the user manual for specific recommendations on maintenance intervals.

- Conduct visual inspections to assess the condition of each component.

- Keep track of performance issues that may indicate a need for replacement.

- Consult with experts or authorized service providers for insights on frequently replaced items.

By systematically evaluating these elements, you can ensure that your equipment remains in top condition, minimizing downtime and enhancing overall productivity.

Maintenance Tips for Kohler Engines

Regular upkeep is essential for optimal performance and longevity of your machinery. By adhering to a structured maintenance routine, you can prevent unexpected breakdowns and enhance the efficiency of your engine. This guide outlines key practices to ensure your unit remains in peak condition.

| Task | Frequency | Tips |

|---|---|---|

| Oil Change | Every 50 hours | Use recommended oil type for better lubrication. |

| Air Filter Inspection | Every 25 hours | Clean or replace to maintain airflow. |

| Fuel System Check | Every season | Ensure no contaminants are present in fuel. |

| Spark Plug Replacement | Every 100 hours | Choose compatible plugs for effective ignition. |

| Cooling System Cleaning | Every 50 hours | Remove debris to prevent overheating. |

Implementing these strategies will contribute to the ultimate reliability and performance of your engine, ensuring it serves you well for years to come.

Where to Purchase Replacement Parts

Finding the right components for your equipment can greatly enhance its performance and longevity. Whether you are looking to replace a worn-out item or upgrade your device, there are several reliable sources available to ensure you obtain quality replacements. This section will guide you through the best options for acquiring these essential elements.

Authorized Retailers

Visiting authorized dealers is one of the most reliable ways to secure genuine components. These retailers typically stock a wide array of items, ensuring that you receive the correct match for your model. Additionally, purchasing from authorized sources often comes with the added benefit of warranties and customer support, giving you peace of mind.

Online Marketplaces

Another convenient option is to explore various online platforms that specialize in equipment components. Websites dedicated to tools and machinery often feature comprehensive catalogs and user-friendly search functions. Be sure to verify the seller’s reputation and check for reviews to ensure that you are making a safe purchase. Comparing prices and shipping options can also help you find the best deal.

Expert Resources for Kohler Support

When facing challenges with your equipment, having access to reliable resources is crucial. Expert support can significantly enhance the efficiency and longevity of your machinery. Here are some valuable avenues to explore for assistance and information.

- Official Manufacturer Website: Always start with the primary source. The official site offers manuals, troubleshooting guides, and FAQs that cover a wide range of topics.

- Online Forums: Community-driven platforms can provide insights from fellow users. Engaging in discussions can help solve common issues and share tips.

- Authorized Service Centers: For more complex problems, reaching out to certified professionals ensures that you receive expert help and genuine components.

- Instructional Videos: Numerous tutorials are available on platforms like YouTube. Visual guidance can simplify understanding and performing repairs.

- Social Media Groups: Joining dedicated groups on platforms like Facebook can connect you with other enthusiasts and experts for real-time advice.

Utilizing these resources not only aids in resolving issues but also fosters a deeper understanding of your equipment, ensuring optimal performance over time.