In the realm of hose management systems, a comprehensive visualization of individual elements is essential for effective maintenance and operation. These schematics provide clarity on how various components interact, ensuring optimal functionality. Familiarity with these layouts can significantly enhance user experience and troubleshooting capabilities.

Exploring these intricate designs allows users to identify essential sections and understand their roles within the overall system. This knowledge not only aids in the installation process but also contributes to the longevity and efficiency of the equipment. Whether you’re a seasoned technician or a novice user, a clear grasp of the configuration will empower you to make informed decisions.

Delving into the specifics of each segment reveals the ultimate intricacies that define performance. By analyzing these arrangements, one can appreciate the thoughtful engineering behind each unit, which ultimately leads to better maintenance practices and reduced downtime.

Understanding Reelcraft Parts Diagrams

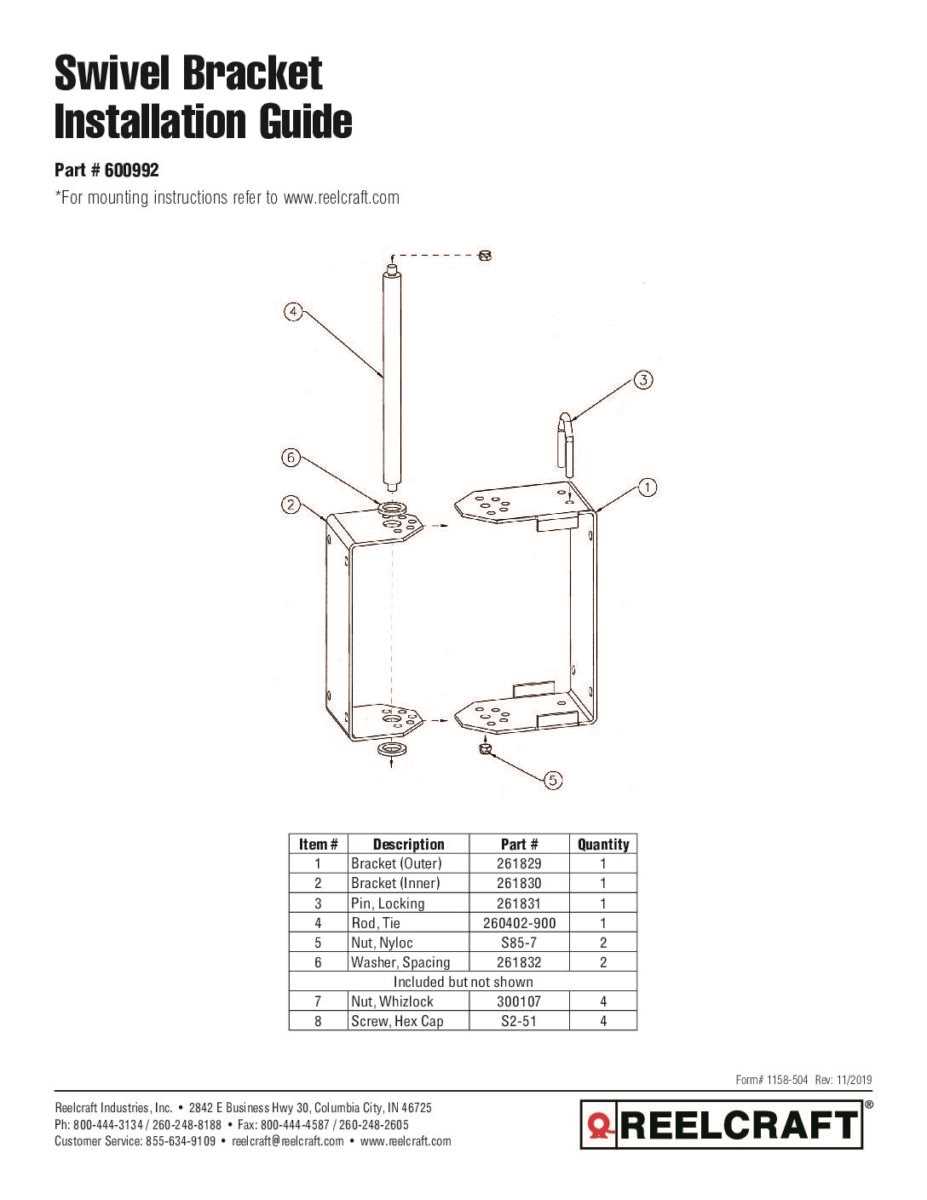

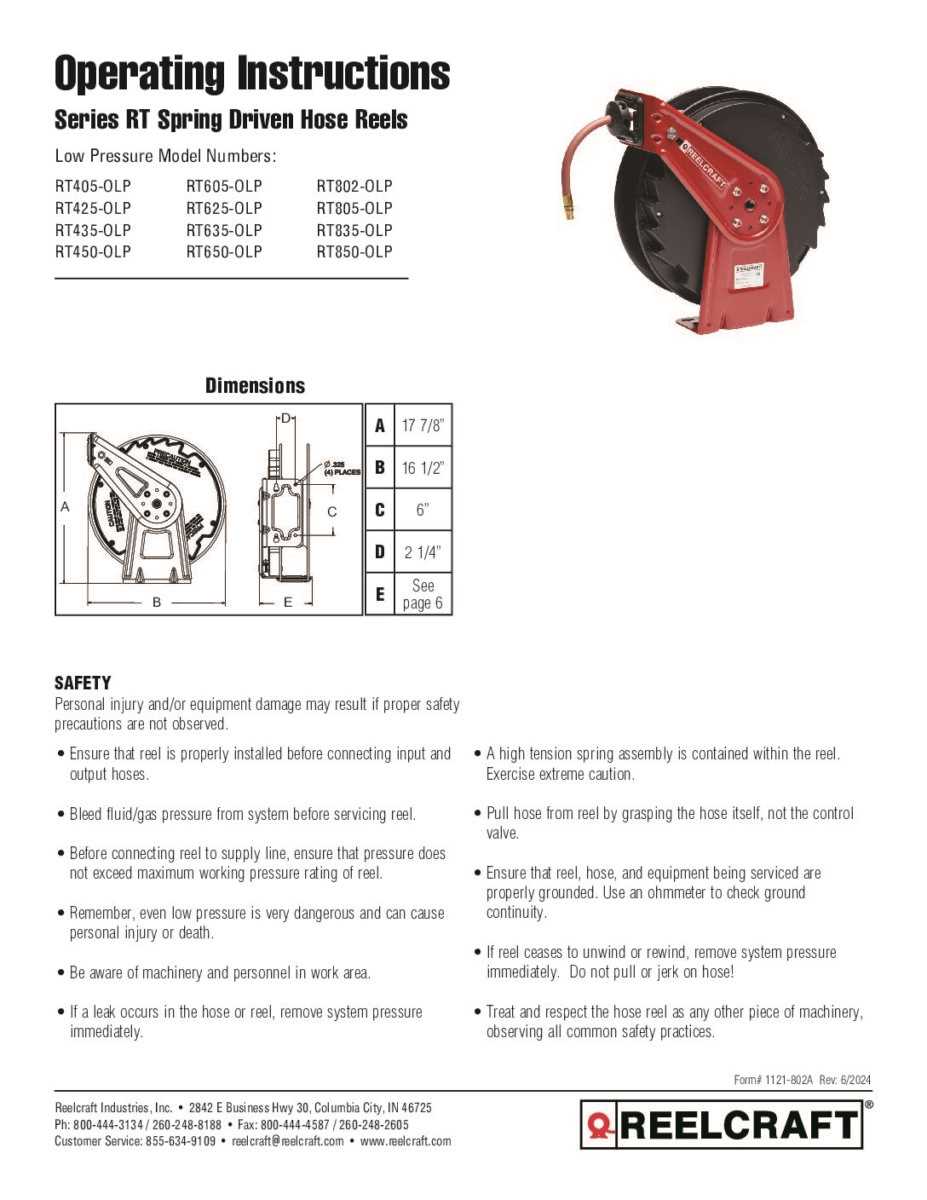

Gaining insight into assembly visuals is essential for effective maintenance and repair of equipment. These illustrations serve as invaluable resources, offering a clear representation of components and their relationships. Familiarity with these visuals enhances troubleshooting skills and simplifies the identification of necessary replacements.

The Importance of Visual Guides

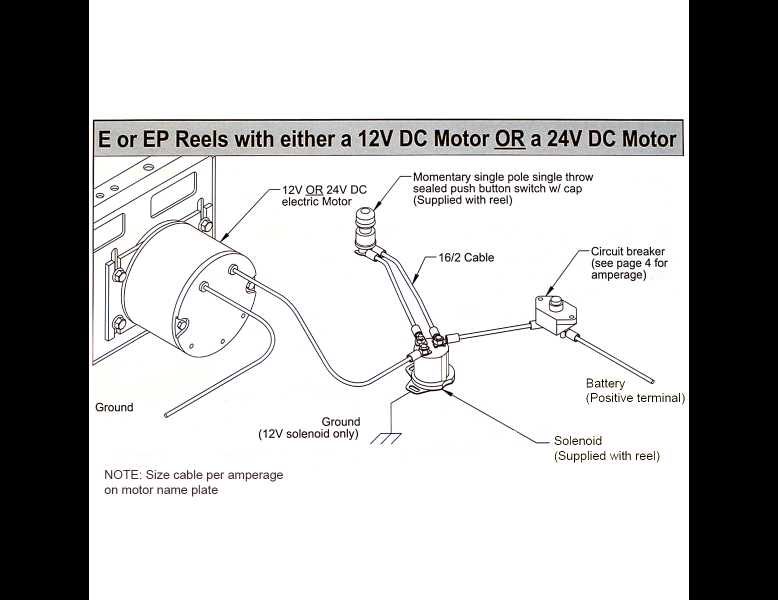

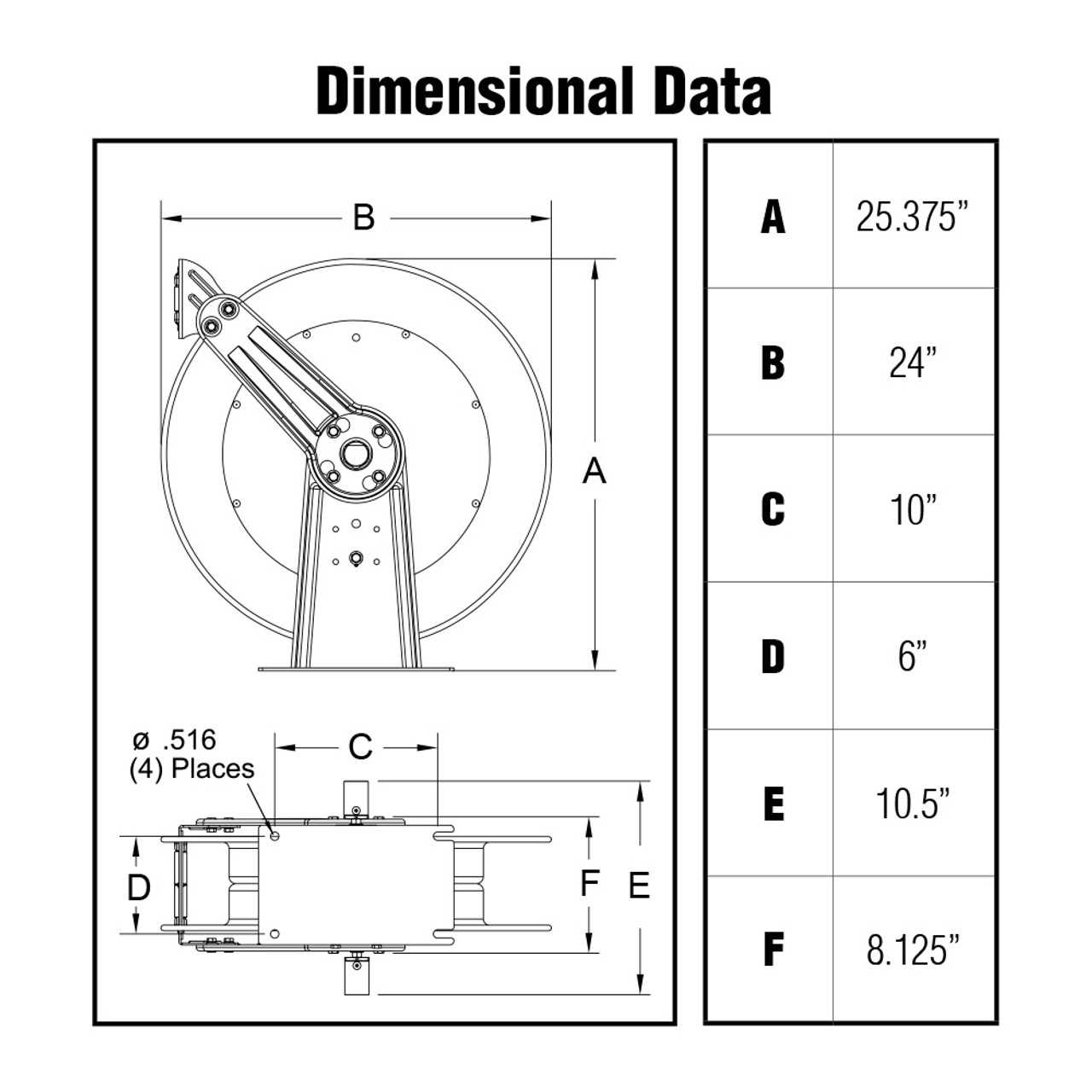

Visual guides play a crucial role in the repair process. They break down complex structures into manageable segments, allowing users to locate and comprehend each individual element. This clarity reduces confusion and streamlines the workflow, making it easier to follow instructions or conduct repairs without prior experience.

Interpreting the Illustrations

Understanding the conventions used in these visuals is vital. Each symbol or label corresponds to specific components, often accompanied by numbers for easy reference. By familiarizing oneself with these indicators, users can efficiently identify required items and understand how they interact within the larger assembly. Attention to detail when analyzing these visuals ensures accurate replacements and optimal functionality of the equipment.

Components of Reelcraft Products

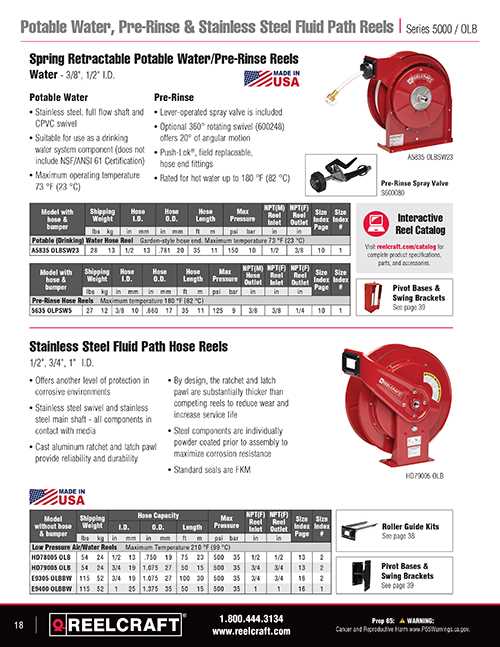

The various elements that constitute these products play a crucial role in their functionality and efficiency. Each component is designed with precision to ensure seamless operation, durability, and user satisfaction. Understanding these integral parts can significantly enhance the overall experience and maintenance of the equipment.

Housings provide structural support, protecting internal mechanisms from external damage. Drums are essential for storing the hoses or cables, allowing for easy deployment and retraction. Guides facilitate smooth movement, ensuring that the stored material remains tangle-free and organized.

Additionally, reels are equipped with various mounting options for versatile installation, catering to different environments and user needs. The inclusion of springs helps in automatic retraction, enhancing user convenience and reducing physical strain.

Lastly, accessories such as nozzles and connectors further optimize the equipment, making it suitable for diverse applications. Together, these components form a cohesive unit that exemplifies quality and reliability.

How to Read a Parts Diagram

Understanding the layout of components is essential for effective maintenance and repair. This visual representation serves as a guide, helping you identify various elements and their relationships. By becoming familiar with the symbols and structure, you can navigate the assembly with confidence and precision.

Familiarize Yourself with the Legend

Most illustrations include a legend or key that explains the symbols used. This section provides essential information regarding each item, including its designation and specific function. Take the time to study this part, as it will enhance your comprehension of the entire layout.

Identify Key Sections

Look for clearly marked areas that group similar components together. These clusters often indicate how parts interact or fit within the overall system. By recognizing these sections, you can more easily locate individual items and understand their roles within the assembly.

Common Issues with Reelcraft Equipment

When utilizing industrial hose reels and similar devices, users often encounter a variety of challenges that can hinder performance and efficiency. Understanding these common problems is crucial for effective troubleshooting and maintenance, ensuring optimal functionality over time.

Frequent Mechanical Failures

Mechanical issues such as excessive wear and tear, misalignment, or malfunctioning components can lead to operational failures. Regular inspections and timely replacements of worn parts can significantly reduce downtime.

Fluid Leakage Problems

Leaks can occur due to damaged hoses, worn seals, or improper connections. Addressing these issues promptly helps maintain safety and prevents fluid loss, which can be costly and environmentally hazardous.

Finding Replacement Parts Easily

Locating the necessary components for your equipment can be a straightforward process if you know where to look. Understanding the right resources and methods will help streamline your search and ensure you get what you need without hassle.

Utilizing Online Resources

The internet is an invaluable tool for sourcing items. Many websites offer comprehensive catalogs and user-friendly search features. By entering the model number or description of the equipment, you can quickly find compatible options. Additionally, forums and community groups can provide recommendations and firsthand experiences.

Consulting Manufacturer Support

Don’t underestimate the importance of direct communication with the manufacturer. Their support teams can offer detailed insights and guidance on identifying the right components. Having your equipment’s serial number handy can expedite the process and lead to the ultimate solution.

Importance of Maintenance for Longevity

Regular upkeep is crucial for extending the lifespan of any mechanical system. By ensuring that components are consistently checked and serviced, potential issues can be identified and resolved before they escalate. This proactive approach not only enhances performance but also minimizes the risk of unexpected failures.

Implementing a routine maintenance schedule fosters reliability and efficiency, allowing systems to operate at their best. Proper care contributes to the overall health of machinery, reducing wear and tear and promoting optimal function. As a result, investment in consistent maintenance translates to significant long-term savings.

Ultimately, a commitment to regular servicing not only safeguards the equipment but also ensures that users can depend on its performance. By prioritizing maintenance, one can maximize productivity and enjoy the benefits of well-functioning machinery for years to come.

Where to Source Genuine Parts

Finding authentic components for your equipment is crucial for maintaining its performance and longevity. Ensuring you acquire high-quality items not only enhances efficiency but also minimizes the risk of future issues.

Authorized Distributors

- Check manufacturer websites for a list of approved vendors.

- Contact local dealers who specialize in your equipment type.

Online Marketplaces

- Visit reputable e-commerce platforms that focus on industrial supplies.

- Look for user reviews and ratings to confirm reliability.

- Verify the seller’s return policy and warranty options.

By utilizing these sources, you can ensure that you are obtaining genuine items, ultimately enhancing your operational success.

Tips for Assembling Reelcraft Products

When putting together these high-quality items, careful attention to detail can greatly enhance the final outcome. Following a structured approach not only simplifies the process but also ensures optimal performance of the equipment. Here are some effective strategies to keep in mind.

Understand the Components

Before starting, take time to familiarize yourself with each element involved. Studying the manual will provide insight into the specific functions and relationships between different pieces, allowing for smoother assembly.

Use the Right Tools

Having the appropriate tools at your disposal is crucial. Make sure to gather everything needed beforehand, as this will help you avoid unnecessary interruptions. Quality tools can significantly reduce the risk of damage during the assembly process.

Innovations in Reelcraft Design Technology

The evolution of design in the realm of fluid management systems has introduced remarkable advancements that enhance efficiency, durability, and user experience. This section explores the latest innovations that have redefined the standards in the industry.

Key Features of Modern Designs

- Advanced Materials: Utilization of lightweight, corrosion-resistant substances to ensure longevity.

- Ergonomic Designs: Focus on user-friendly configurations that minimize strain during operation.

- Smart Technology: Integration of digital monitoring systems for enhanced functionality.

Impact on Performance

- Increased efficiency due to optimized fluid flow.

- Reduction in maintenance costs through durable materials.

- Improved safety features that protect users and equipment.